Humidification technology and humidification system for large power PEM fuel battery test platform

A fuel cell and test bench technology, applied in the field of humidification technology and humidification system, can solve problems such as submerged electrodes, protons cannot pass through, and affect battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

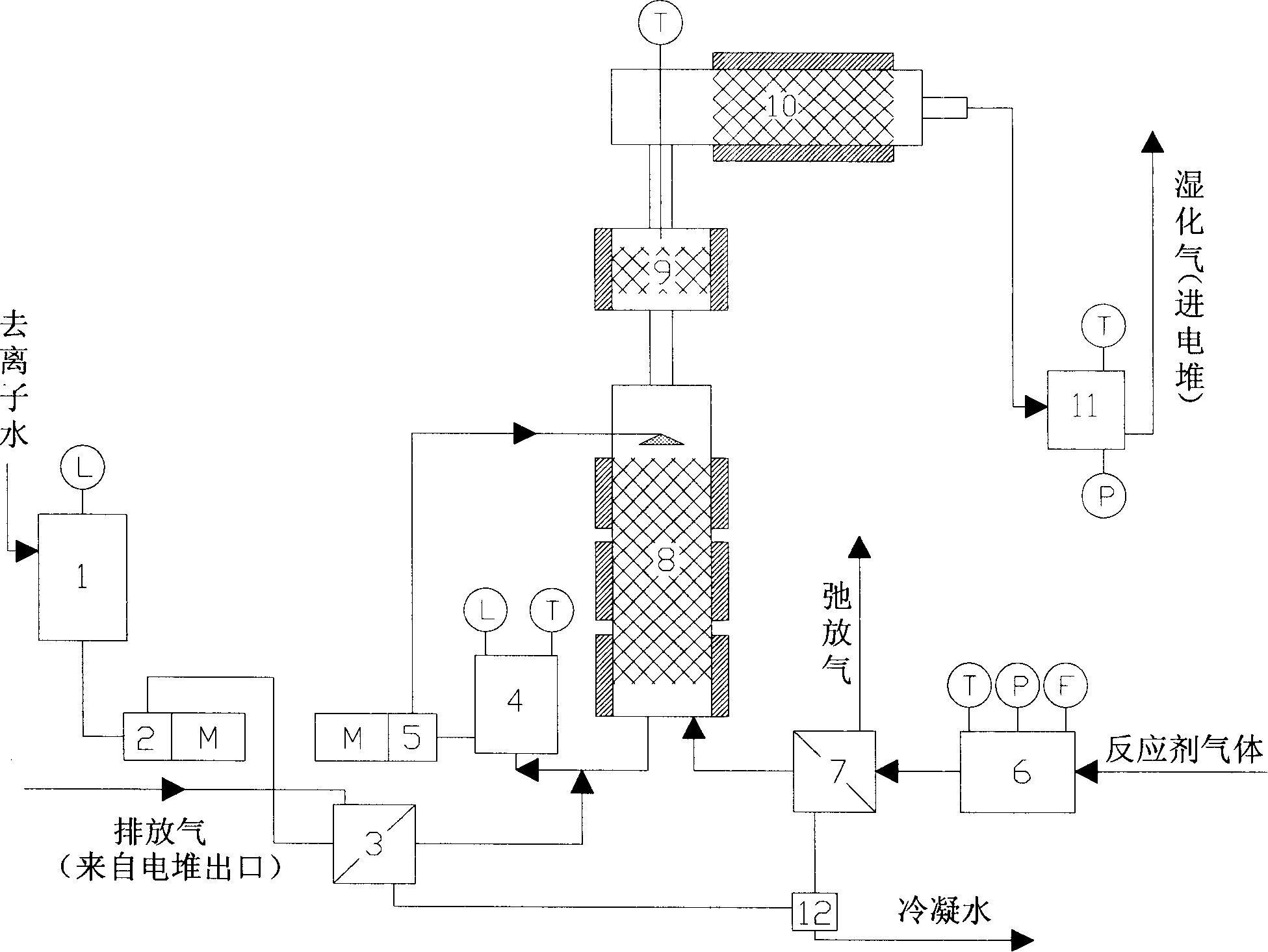

[0013] The deionized water from the deionized water pipeline enters the deionized water tank 1 through the liquid level gauge of the normal pressure deionized water tank 1 to control the solenoid valve. The deionized water in the deionized water tank flows through the heat exchanger 3 to raise the temperature by the replenishment pump 2 and then is sent to the supplementary water heating tank 4 with liquid level control according to the specified flow rate. According to the system pressure of the test bench, the supplementary water pump 2 can be a peristaltic pump, a diaphragm pump or a centrifugal pump. A stepping motor or an AC frequency conversion motor can be used to adjust the motor speed according to the liquid level of the water replenishing heating tank 4, thereby controlling the replenishing water flow of the deionized water, and maintaining the deionized water in the replenishing water heating tank 4 at a constant liquid level . The replenishing water heating tank 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com