A compound proton exchange film for self-humidity increase fuel battery and its making method

A proton exchange membrane and fuel cell technology, applied in the field of proton exchange membranes, can solve the problems of complex electroless plating methods, long membrane production cycle, poor battery performance, etc., to eliminate mixed overpotential, increase proton conductivity, and improve battery efficiency. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

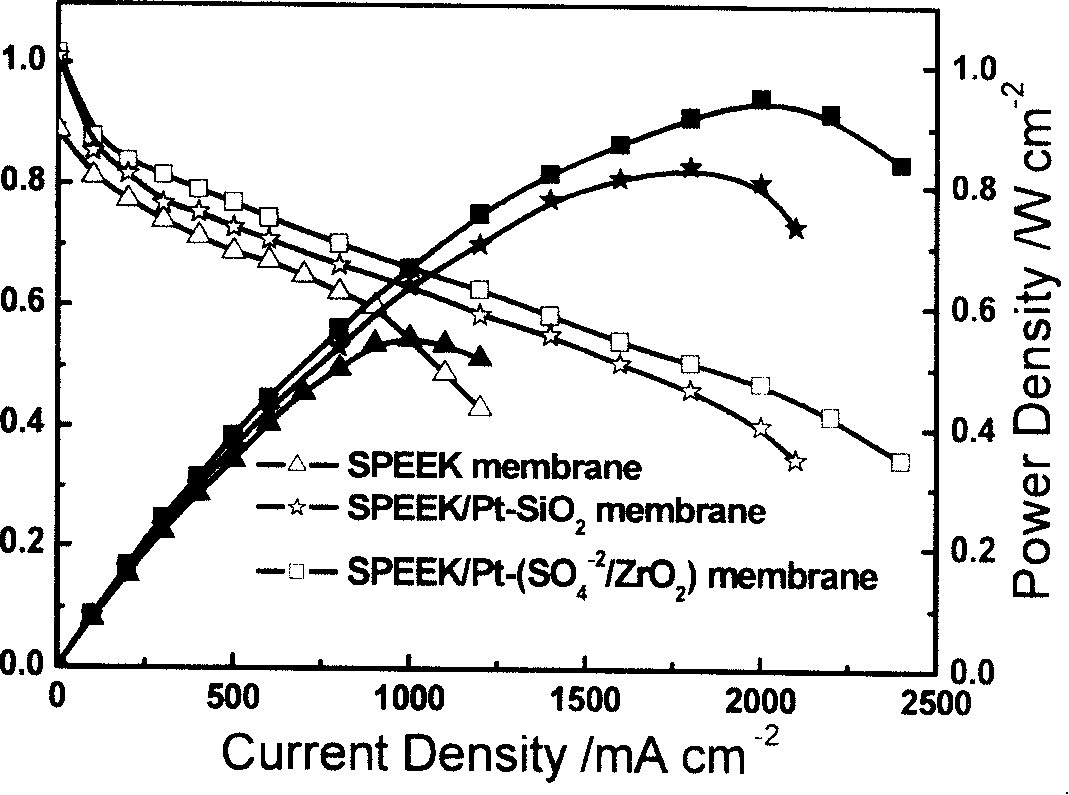

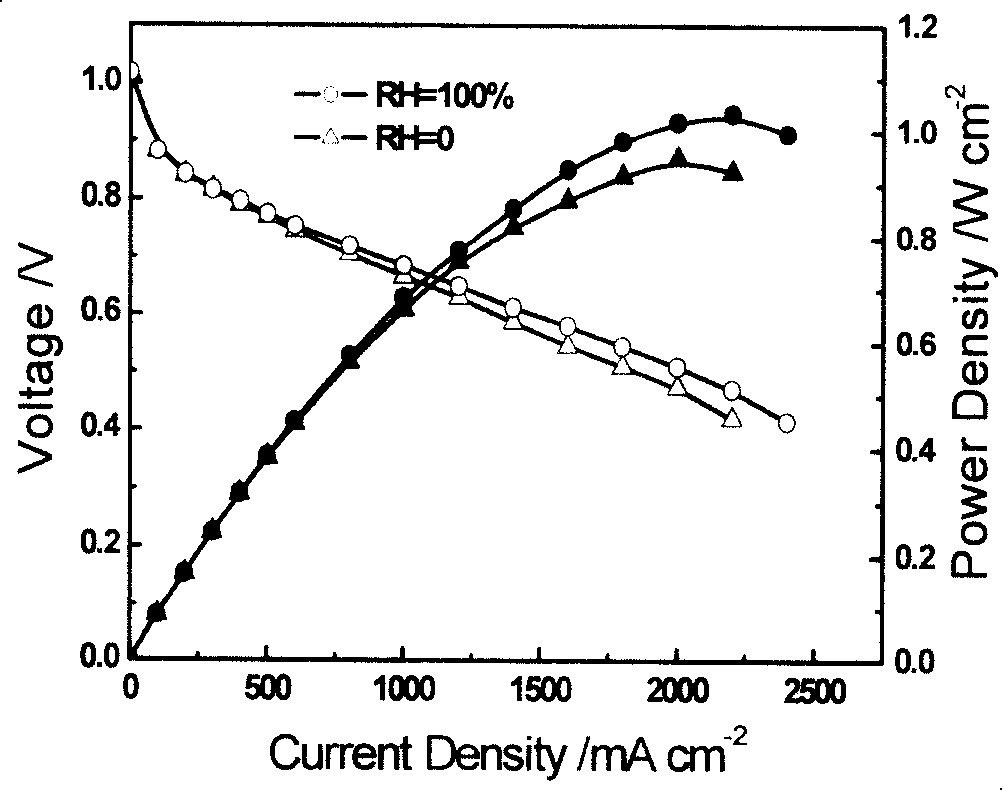

[0038] The preparation of the supported catalyst is to use the impregnation reduction method to load the nano-scale catalytic active component carrier with the catalytic active component. The role of the catalyst is to chemically catalyze the interpenetrating H 2 and O 2 Water is generated to wet the proton exchange membrane. The role of the catalytically active component carrier is to absorb the water generated on the surface of the catalytically active component and the electrochemically generated water on the cathode side, and release water in time to wet the membrane when the membrane needs moisture. In addition, the carrier can provide additional protons in the composite membrane Conduction path, thereby improving the conductivity of the composite film, improving the open circuit voltage and battery performance of the battery.

[0039] The self-humidifying composite membrane in the present invention includes two types, one is to dissolve the polymer electrolyte with a hi...

Embodiment 1

[0041] Example 1: 3.7mg / ml of H 2 PtCl 6 solution and nano-SO -2 4 / ZrO 2 Immerse an equal volume (50ml) at room temperature for 24h, and then use H at 200°C 2 Reduction 10h, prepared into supported catalyst Pt / (SO -2 4 / ZrO 2), the Pt loading was 0.2wt.%.

Embodiment 2

[0042] Embodiment 2: the HAuCl of 3.7mg / ml 4 solution and nano-SO -2 4 / Fe 2 o 3 Immerse an equal volume (50ml) at room temperature for 24h, and then use H at 120°C 2 After reduction for 10 h, the supported catalyst Au / (SO -2 4 / Fe 2 o 3 ), the Au loading is 10 -3 wt.%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com