Waste gas treatment equipment with aeration groove of biological purification tower

A technology of waste gas treatment equipment and purification tower, which is applied in the direction of air quality improvement, chemical instruments and methods, and separation of dispersed particles. It can solve the problems of large investment, high energy consumption, and incomplete treatment, and achieves convenient operation and management. The effect of small area and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

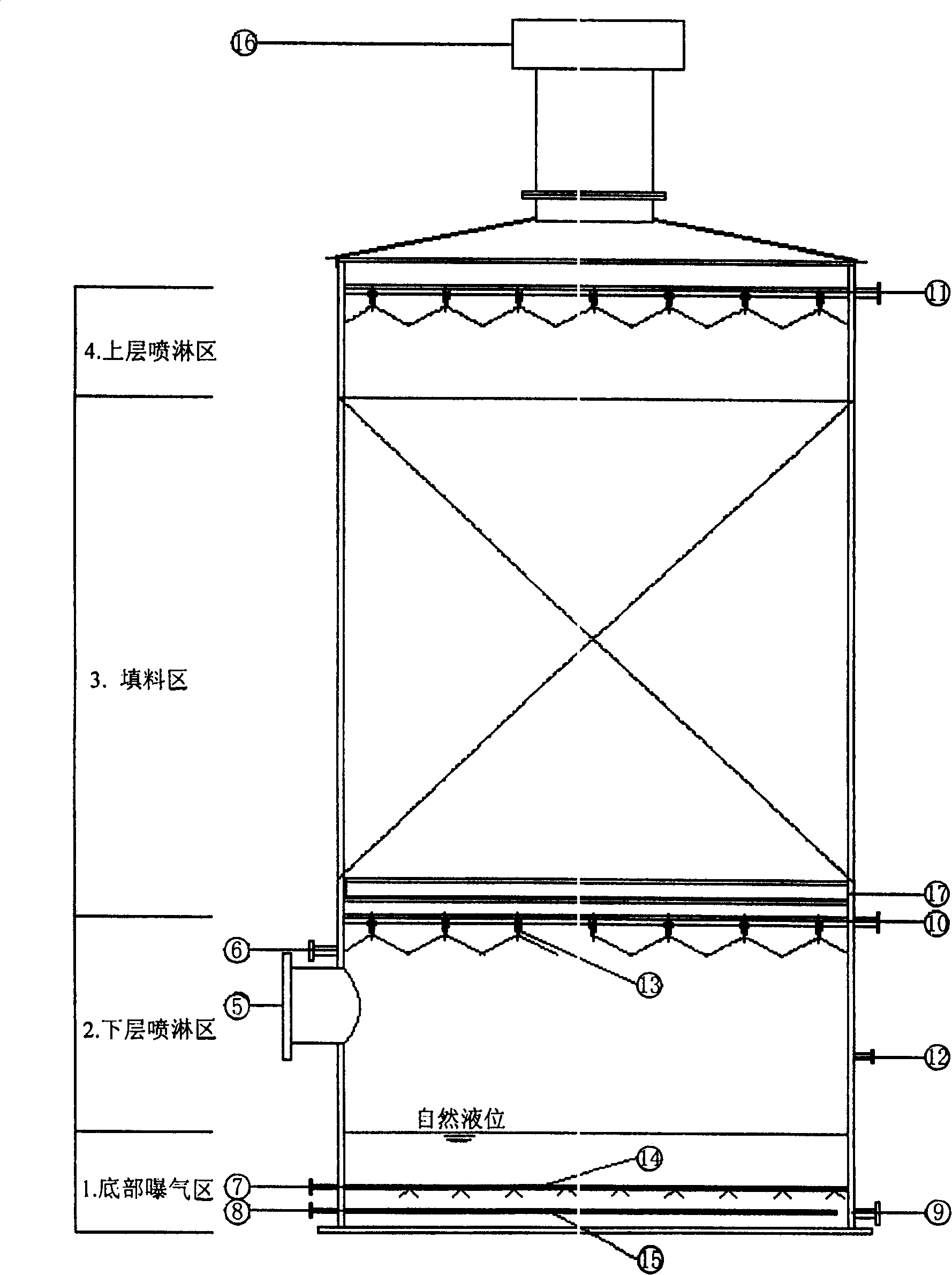

[0033] The biological purification tower equipment is made of carbon steel structure, and the inner wall is lined with rubber for anticorrosion. The diameter of the tower body is 4 meters, the height is 8 meters, and the total volume is 100 cubic meters. The equipment is equipped with 14 perforated aeration pipes and 15 steam heating tubes at the bottom The coil consists of 1 bottom aeration tank, 2 lower spray areas equipped with spiral nozzles, 4 upper spray areas and 3 packing areas.

[0034] There are 7 air inlets, 8 steam inlets, and 9 mixed liquid outlets on the side wall of the aeration zone at the bottom of the equipment. The entrance is connected; the side wall of the 2nd lower layer of the equipment is equipped with 5 exhaust gas inlets, 10 lower layer spray liquid inlets, 6 nutrient solution inlets, and 12 clean water inlets, which are respectively connected to the outlet of the induced draft fan outside the tower and the circulation pump outside the tower. The outl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com