Combination technique for producing olefin hydrocarbon with mixed C_4

A technology of mixing C4 and olefins, which is applied in the direction of hydrocarbon cracking, organic chemistry, etc., can solve the problem that C4 resources are not fully and effectively utilized, and achieve the goal of meeting market demand, avoiding interference, and high propylene yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

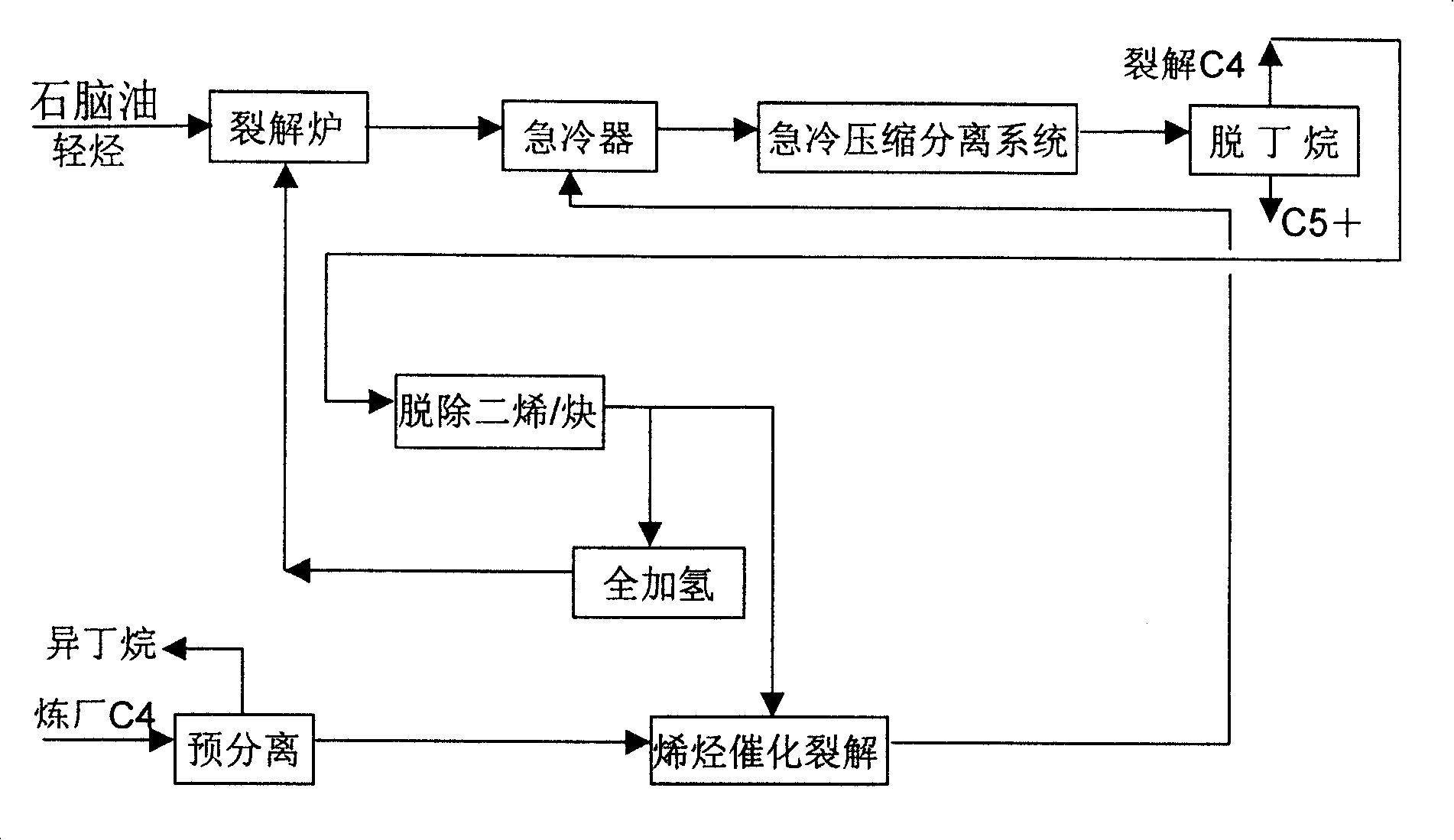

[0051] Reference attached Figure 4 Describe the process.

[0052] The cracked gas produced by thermal cracking of naphtha has a temperature of 820°C and a pressure of 0.15MPa. It enters the quenching system and is cooled to 40°C. The heavy components are removed, and then enters the compression separation system to obtain ethylene, propylene, mixed C4 and C5 respectively. Equal weight components. The mixed C4 component obtained from the separation system has a temperature of 40°C and a pressure of 0.3 MPa. The main composition and its mass percentage content are: 1,3-butadiene 50%, isobutane 0.5%, n-butane 2.3%, trans -2-butene 7.3%, cis-2-butene 5.1%, isobutene 22.8%, 1-butene 10%. The cracked mixed C4 enters the selective hydrogenation reactor to remove the diolefins and alkynes therein. The reactor is a fixed-bed reactor, and the catalyst is a Group VIII metal catalyst added with rare earth elements, such as the catalyst for the selective hydrogenation of alkynes and di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com