Method for producing verelite microsphere for surface decoration of conductive polyaniline nano-wire

A technology of polystyrene microspheres and conductive polyaniline, which is applied in the field of preparing polystyrene microspheres modified by conductive polymer nanowires, can solve the problems that the microspheres have not been reported yet, and the polyaniline coating layer is irregular. To achieve the effects of short cycle time, high production efficiency and mild synthesis conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

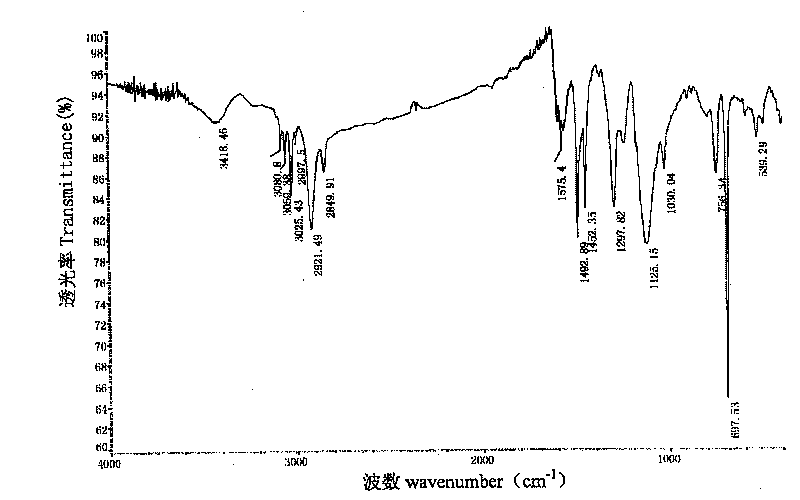

Embodiment 1

[0023] Take 10ml of 1mol / L hydrochloric acid aqueous solution and add it to a three-necked flask equipped with a magnetic stirring bar, add 0.025g of dodecyltrimethylammonium bromide under stirring conditions, and stir until transparent to obtain 2.5g / L dodecyltrimethylammonium bromide Alkyltrimethylammonium bromide solution. Add 0.5 g of polystyrene (PS) microspheres into the solution, and stir for 20 min. Dissolve 0.05 g of aniline monomer in 2.5 ml of n-hexane to obtain a 20 g / L aniline monomer solution. Then, the aniline monomer solution was added into the PS microsphere-dodecyltrimethylammonium bromide mixed solution under stirring. Add nitrogen gas and stir for 20 minutes, and the system appears a relatively uniform milky white color. Add 0.114 g of ammonium persulfate to 10 ml of 1 mol / L hydrochloric acid aqueous solution, and stir to dissolve. Then the ammonium persulfate solution was added dropwise into the above-mentioned emulsion containing PS microspheres with a...

Embodiment 2

[0027] The reaction steps are as in Example 1, the amount of dodecyltrimethylammonium bromide is changed to 0.02g, so that the concentration becomes 2g / L, and the product surface modified conductive polymer nanowire functionalized polystyrene microspheres can be obtained .

Embodiment 3

[0029] The reaction steps are as in Example 1, and the amount of dodecyltrimethylammonium bromide is changed to 0.05g, so that the concentration becomes 5g / L, and the product surface-modified conductive polymer nanowire functionalized polystyrene microspheres can be obtained .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com