Single-component ketoxime removing type room temperature vulcanized silicone rubber composition

A silicone rubber composition and room temperature vulcanization technology, which is applied in the field of one-component deketoxime type room temperature vulcanization silicone rubber composition, can solve the problems of poor leveling, short surface drying time, etc., and achieve good high and low temperature performance, electrical insulation Excellent performance, excellent water resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

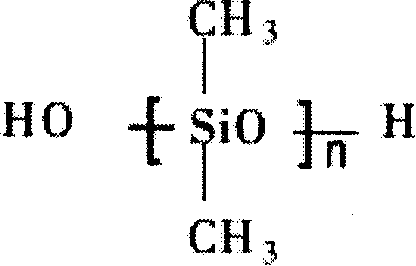

[0025] This example is used to illustrate the one-component deketoxime type room temperature vulcanized silicone rubber provided by the present invention and its preparation method.

[0026] Under the protection of dry nitrogen, 1 kg of hydroxyl-terminated polydimethylorganosiloxane (trade name: 107 glue, 25 ° C viscosity of 3000 centipoise), 50 g of fumed silica (specific surface area of 200 square meters / grams) and 100 grams of trimethylsilyl-terminated polyorganosiloxane (viscosity of 1000 centipoise at 25° C.) were ground and mixed evenly, and mixed with 80 grams of anilinomethyl tributylketoxime silane, 30 grams of vinyl The cross-linking catalytic mixture of trimethylketoxime silane and 3 g of dibutyltin dilaurate was uniformly mixed, and then mixed uniformly with all the above organosiloxane polymers under stirring. Then 15 grams of γ-aminopropyltriethoxysilane, 15 grams of γ-(2,3-epoxypropoxy)propyltrimethoxysilane were stirred with the above mixture for 30 minutes...

Embodiment 2

[0032] This example is used to illustrate the one-component deketoxime type room temperature vulcanized silicone rubber provided by the present invention and its preparation method.

[0033] Under the protection of dry nitrogen, 1 kg of hydroxyl-terminated polydimethylorganosiloxane (trade name: 107 glue, 25 ° C viscosity of 3000 centipoise), 50 g of fumed silica (specific surface area of 200 square meters / gram) and 100 grams of trimethylsilyl-terminated polyorganosiloxane (viscosity 1000 centipoise at 25° C.) were ground and mixed evenly, and then stirred and mixed evenly with 10 grams of hexamethyldisilazane, and then mixed with 80 grams of anilinomethyl tributylketoxime silane, 20 grams of vinyl tributylketoxime silane, 10 grams of tetrabutylketoxime silane and 3 grams of dibutyltin dilaurate cross-linking catalytic mixture mixed with the above After the mixture is stirred and mixed evenly, it is mixed with 10 grams of γ-aminopropyltriethoxysilane and 20 grams of γ-(2,3...

Embodiment 3

[0035] This example is used to illustrate the one-component deketoxime type room temperature vulcanized silicone rubber provided by the present invention and its preparation method.

[0036] Under the protection of dry nitrogen, 1 kg of hydroxyl-terminated polydimethylorganosiloxane (trade name: 107 glue, 25 ° C viscosity of 3000 centipoise), 50 g of fumed silica (specific surface area of 200 square meters / gram) and 100 grams of trimethylsilyl-terminated polyorganosiloxane (viscosity 1000 centipoise) ground and mixed with 10 grams of hexamethyldisilazane and mixed with 30 grams of anilinomethyl tri The cross-linking catalytic mixture of methyl ethyl ketoxime base silane, 80 grams of phenyl tributylketoxime base silane and 3 grams of stannous octoate mixed and mixed with the above mixture after mixing evenly with 30 grams of γ-(2,3-glycidyl oxide ) Propyltrimethoxysilane was uniformly mixed under stirring conditions to obtain the one-component deketoxime type room temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com