Deinking agent

A technology of deinking agent and surfactant, applied in the field of papermaking, can solve the problems of insufficient deinking agent performance, aggravating environmental pollution, poor deinking agent ability, etc., and achieves excellent operability, reduced pollution, and low residual ink amount. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

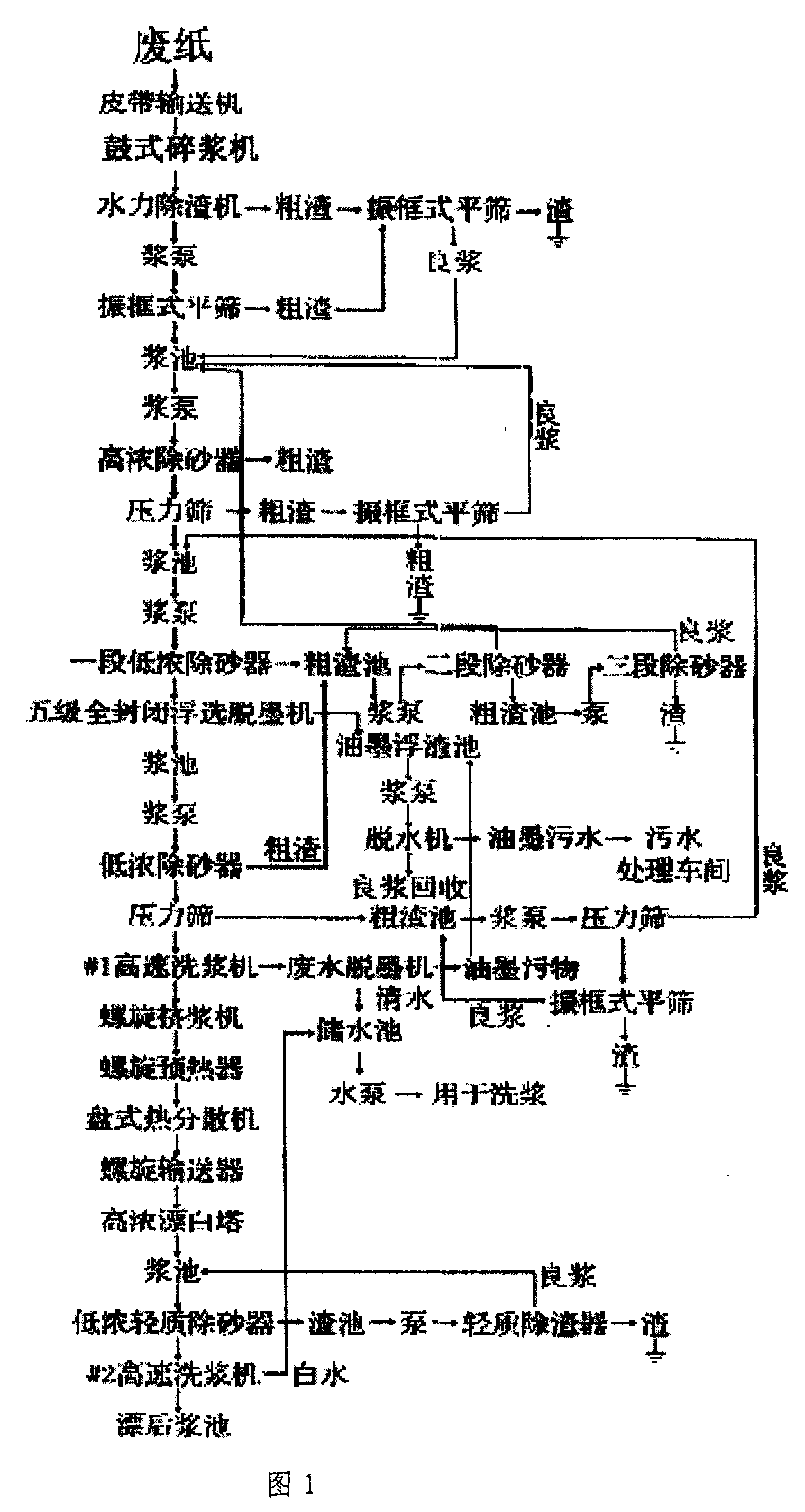

Method used

Image

Examples

Embodiment 1

[0031] To prepare 1 kg of this deinking agent, you need:

[0032] water 400g

[0033] Polyoxyethylene polyol ester 100g

[0034] Stearate 300g

[0035] Lauryl Sulfate 50g

[0036] Sodium Lignosulfonate 20g

[0039] Polyoxyethylene alkyl ether 100g

[0040] The above-mentioned chemicals are all purchased from the market, wherein polyoxyethylene polyol ester and polyoxyethylene alkyl ether are commercially available nonionic surfactants, and their consumption is calculated as 100%.

[0041] Start the mixer, and add the above-mentioned medicines into the mixer one by one, with an interval of 15 minutes after each raw material is cast, and the medicine will be in a slurry form after being completely dissolved. Stir for 20 minutes after all the medicines are dispensed and then discharge.

[0042] The formulated deinking agent remained stable within 6 months without delamination and had a pH of 9.

[0043] In the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com