Method for manufacturing polyesterimide enamelled wire paint

An enameled wire varnish and manufacturing method technology, applied in the direction of coating, etc., can solve the problems of low adhesion, small DV value, poor flexibility of polyesterimide enameled wire, etc., achieve delicate reaction, improve adhesion, and process margin of coating wire big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

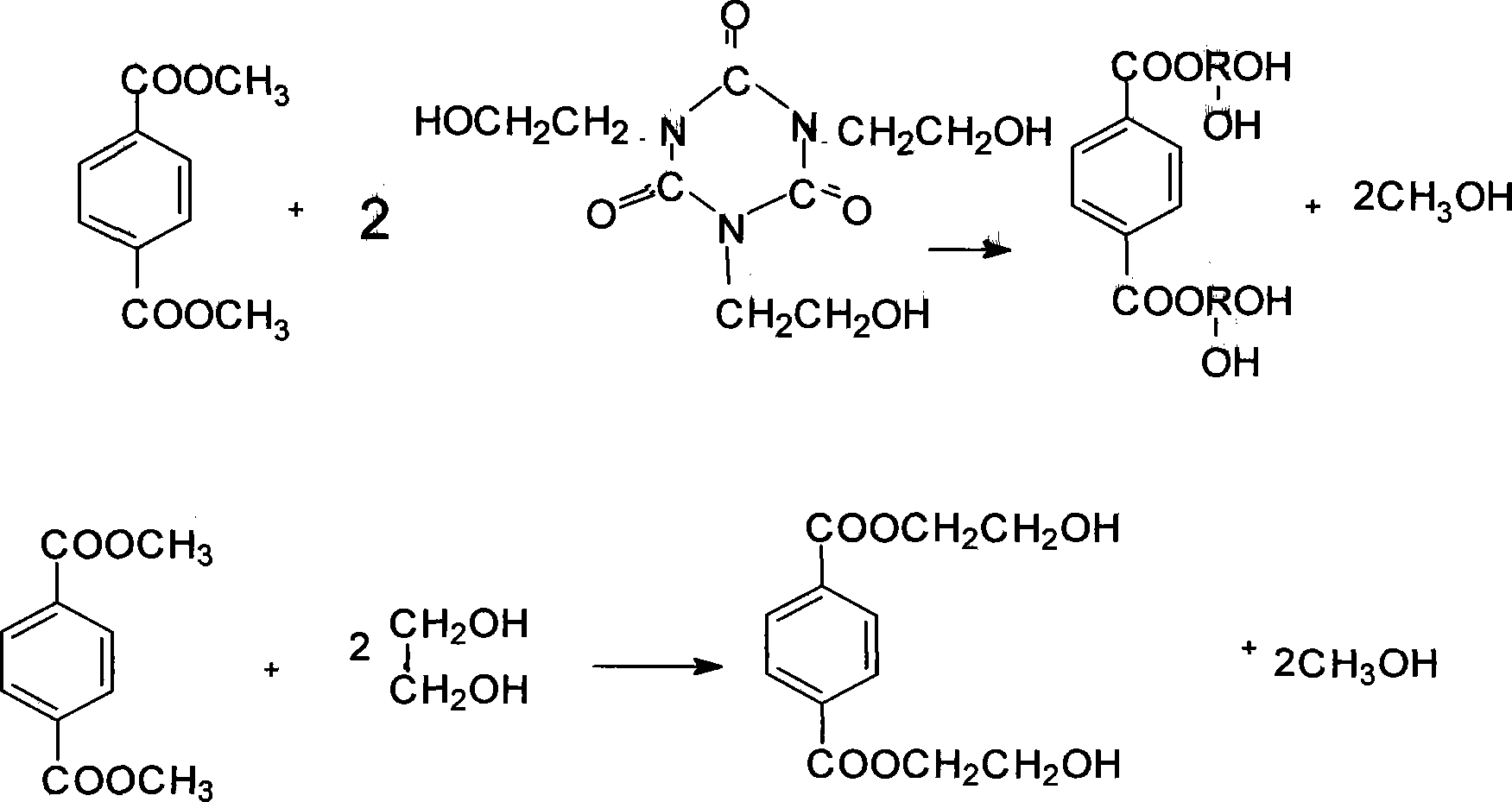

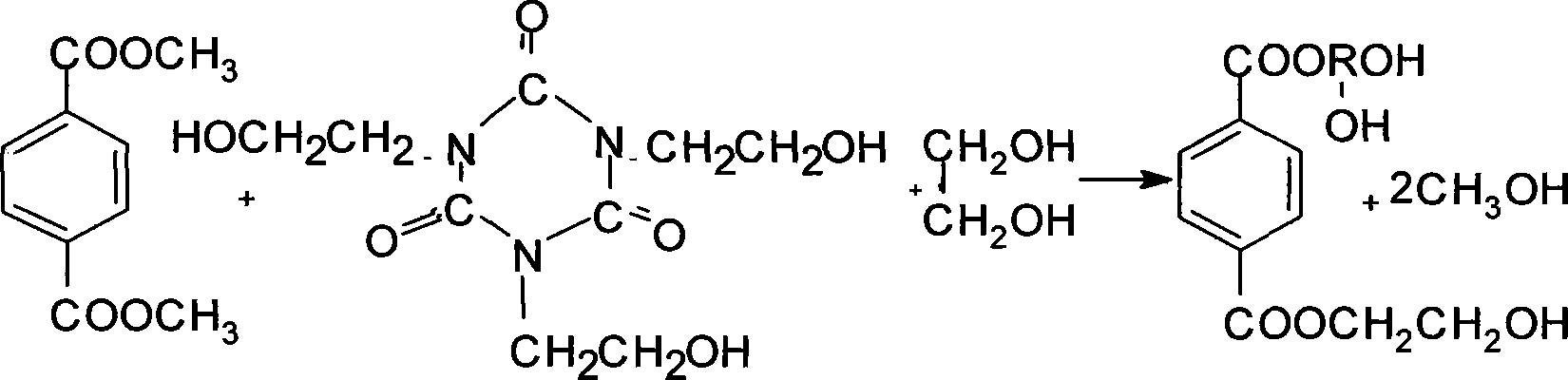

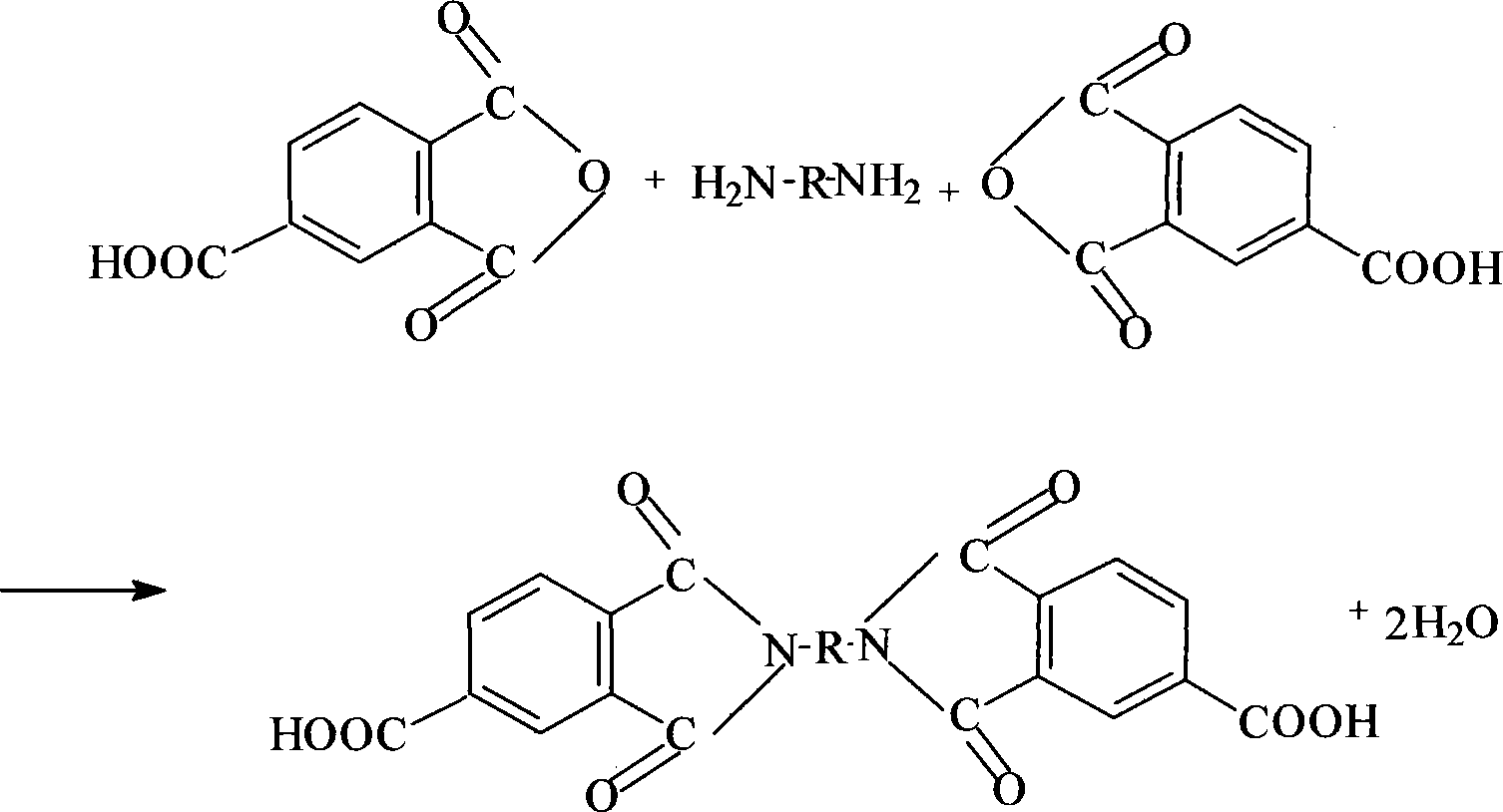

Method used

Image

Examples

Embodiment 1

[0041]Put 400g of dimethyl terephthalate (DMT), 200g of ethylene glycol, 430g of Sek, 270g of D33 monomer, 250g of xylenol and 2g of butyl orthotitanate into the reactor, and put 410g of trimellitic anhydride and 4 , 207g of 4'-diaminodiphenyl ether, reacted at 150°C for 1 hour and then raised the temperature to 170°C, put in the second batch of trimellitic anhydride 410g and 207g of 4,4'-diaminodiphenyl ether, continued the reaction for 2 hours, and then added the second Three batches of 410g of trimellitic anhydride and 207g of 4,4'-diaminodiphenyl ether were kept at 170°C for one hour, then raised to 200°C-205°C at 10 / °C, kept warm until transparent, and carried out central control testing. The ICI viscosity reached 200 Centipoise~500 centipoise / 200℃. After passing the test, add cresol, keep stirring at 155°C for 4 hours, then add cresol, xylene and C9 high-boiling aromatic hydrocarbon solvent, and finally add an appropriate amount of polybutyl titanate, phenolic resin and ...

Embodiment 2

[0043] Put 400g of dimethyl terephthalate, 200g of ethylene glycol, 260g of sek, 87g of trimethylolpropane, 270g of D33 monomer, 250g of xylenol and 2g of butyl orthotitanate into the reaction kettle, and put it into the reactor at 80°C 410g of trimellitic anhydride and 204g of 4,4'-diaminodiphenylmethane were reacted at 150°C for 1 hour, then the temperature was raised to 170°C, and the second batch of trimellitic anhydride 410g and 204g of 4,4'-diaminodiphenylmethane were added to continue the reaction for 2 hours , and then add the third batch of 410g of trimellitic anhydride and 204g of 4,4'-diaminodiphenylmethane, and keep it at 170°C for one hour, then raise the temperature at 10 / °C to 200°C-205°C and keep it transparent until it is transparent, and then carry out the ICI viscosity detection in the central control 200 centipoise to 500 centipoise / 200°C, add cresol after passing the test, keep stirring at 160°C for 4 hours, then add cresol, xylene and C9 high-boiling aroma...

Embodiment 3

[0045] Put 400g of dimethyl terephthalate, 200g of ethylene glycol, 260g of sek, 50g of trimethylolpropane, 250g of D33 monomer, 200g of xylenol and 2g of butyl orthotitanate into the reaction kettle, and put it into the reactor at 80°C 410g of trimellitic anhydride and 204g of 4,4'-diaminodiphenylmethane were heated up to 170°C after reacting at 150°C for 1 hour, and the second batch of trimellitic anhydride 410g and 204g of 4,4'-diaminodiphenyl ether were added to continue the reaction for 2 hours, and then Add the third batch of 410g of trimellitic anhydride and 204g of 4,4'-diaminodiphenylmethane, heat it at 170°C for one hour, then heat it at 10 / °C to 200°C-205°C until it is transparent, and carry out the central control to detect that the ICI viscosity reaches 200 centimeters Poise ~ 500 centipoise / 200 ° C, add cresol after passing the test, add cresol, xylene and high boiling point aromatic hydrocarbon solvent S100 after stirring at 170 ° C for 5 hours, and finally add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com