Rare earth modified photocatalyst as well as degradable plastic film prepared thereby and preparation method thereof

A rare earth modification, photocatalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as plastic pollution, achieve simple preparation, visible light Improved utilization and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

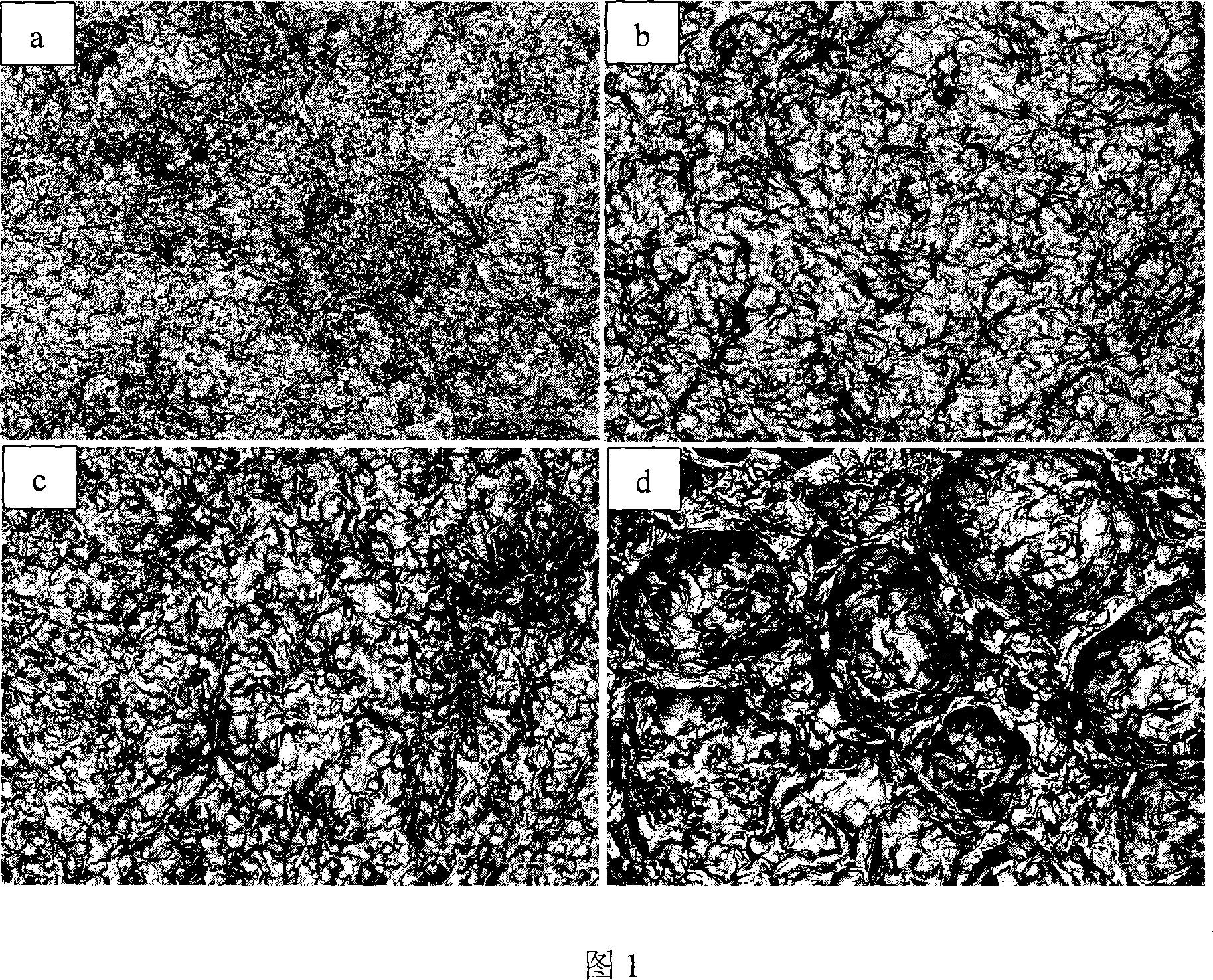

Image

Examples

Embodiment 1

[0025] Embodiment 1: Add Ce2.0%-TiO 2 with TiO 2 Photocatalytic Degradation Comparison of Powder Composite Films

[0026] (1) Ce2.0%-TiO 2 (weight percent) and TiO 2 Powder preparation: Mix 17ml butyl titanate with 40ml 95% ethanol to form solution A; 1ml 1mol·l -1 Ce(NO 3 ) 3 Add the solution to a mixture of 10ml glacial acetic acid, 40ml 95% ethanol and 9ml deionized water to obtain solution B; drop solution A into solution B, stir for 1h to form a uniform transparent sol, and age at room temperature for 2d to form After gelling, dry it at 373K, grind it into powder, and heat-treat it at 737K for 2 hours to get Ce-doped TiO 2 Powder, denoted as Ce2.0%-TiO 2 . Preparation of pure TiO 2 The method is the same as the above method, except that Ce ions are not added. Studies have shown that Ce2.0%-TiO 2 The absorption band edge of pure TiO 2 The obvious red shift, and in the ultraviolet and visible parts Ce2.0%-TiO 2 The absorption spectrum of pure TiO 2 The absorpt...

Embodiment 2

[0028] Example 2: Adding Ce2.0%-TiO 2 with TiO 2 Photocatalytic Degradation of Sol Composite Films

[0029] (1) Ce2.0%-TiO 2 (weight percent) and TiO 2 Sol preparation: Dissolve 8g of titanium sulfate in ammonia water, add 1ml of 1mol·l -1 Ce(NO 3 ) 3 Solution, to obtain an aqueous solution containing a certain concentration of Ti, take 80ml and place it in a 200ml stainless steel reactor with a polytetrafluoroethylene lining at 120°C for hydrothermal crystallization for 12h, filter, wash, and use 0.2mol l -1 BaCl 2 Test solution test SO 4 2- Until it is washed, mix the filter cake with nitric acid solution according to the required preparation concentration and place it in a constant temperature water bath at 333-353 K for 10-20 hours to obtain TiO with a Ce doping amount of 2.0%. 2 Sol, denoted as Ce2.0%-TiO 2 -sol. Preparation of pure TiO 2 The method is the same as the above method, except that Ce ions are not added.

[0030] (2) Add Ce2.0%-TiO 2 Composite fi...

Embodiment 3

[0031] Example 3: Adding TiO with different Ce doping ratios 2 Photocatalytic Degradation of Composite Thin Films

[0032] (1) Different Ce doping ratio-TiO 2 Preparation of powder: same as above-mentioned Example 1 step (1), but adjust the ratio of rare earth elements and titanium (atomic concentration) to be 0.2%, 0.7% and 1.2%, respectively, to obtain Ce0.2%-TiO 2 , Ce0.7%-TiO 2 and Ce1.2%-TiO 2 Catalyst powder or sol. Analysis shows that, the same as the photocatalyst made in embodiment 1, their absorption band edges are all relatively pure TiO 2 The obvious red shift, and the absorption spectrum in the ultraviolet and visible part is better than that of pure TiO 2 The absorption spectrum is strong, and it has the activity of degrading the film under ultraviolet and visible light.

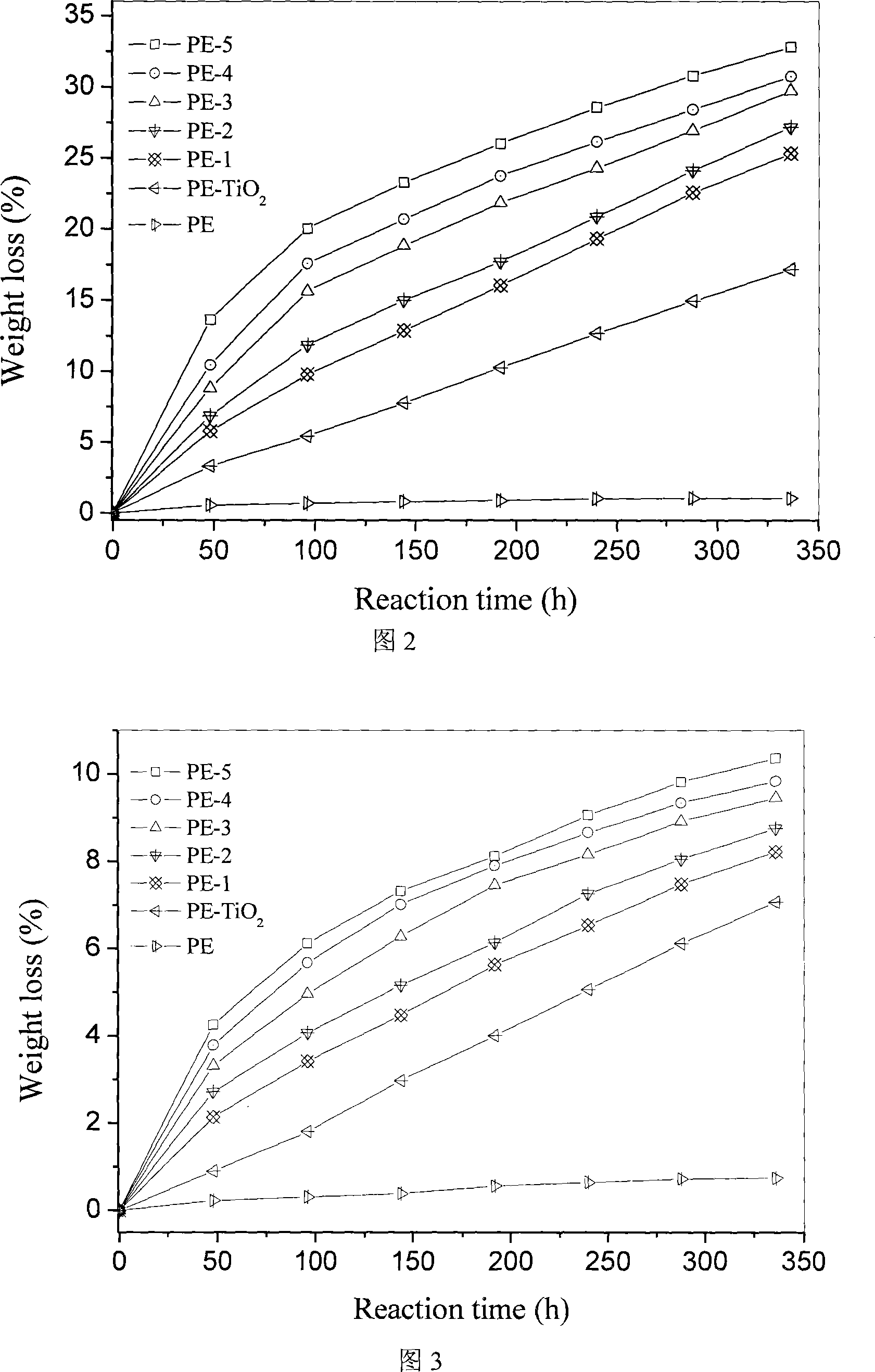

[0033] (2) Same as step (2) of the above-mentioned Example 1, TiO with different Ce doping ratios added 2 composite film. The research shows that, in the same illumination time, the dop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com