Quick start-up palladium membrane components transferring heat by small-scale passage

A fast-start, small-scale technology, applied in the direction of using solid contact hydrogen separation, hydrogen separation, etc., can solve the problems of poor vibration resistance, easy breakage of palladium alloy film, long time, etc., to reduce the heating time and the hydrogen transmission rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific examples. It should be noted that the examples cited are only used to further illustrate the technical features of the present invention, rather than to limit the present invention.

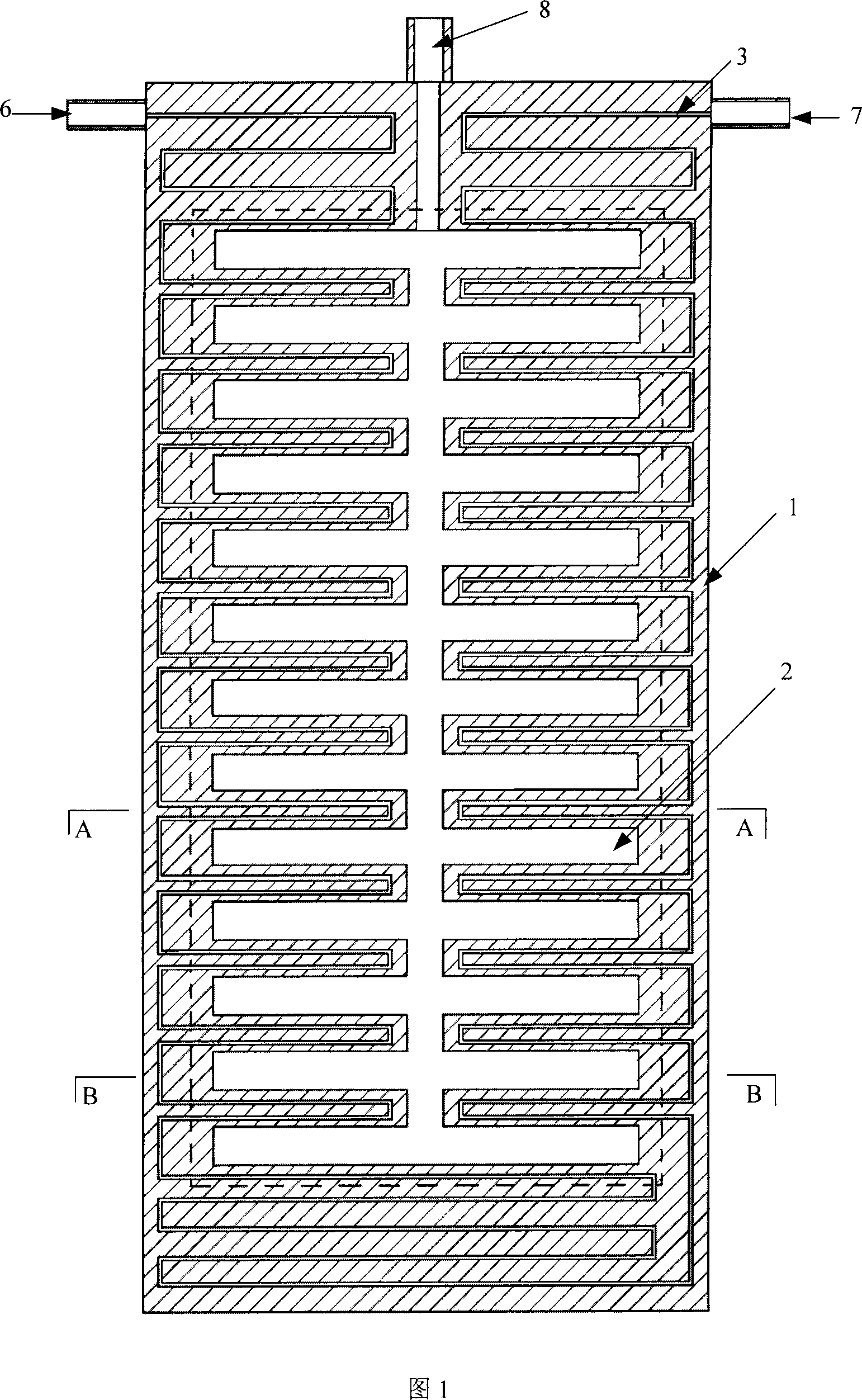

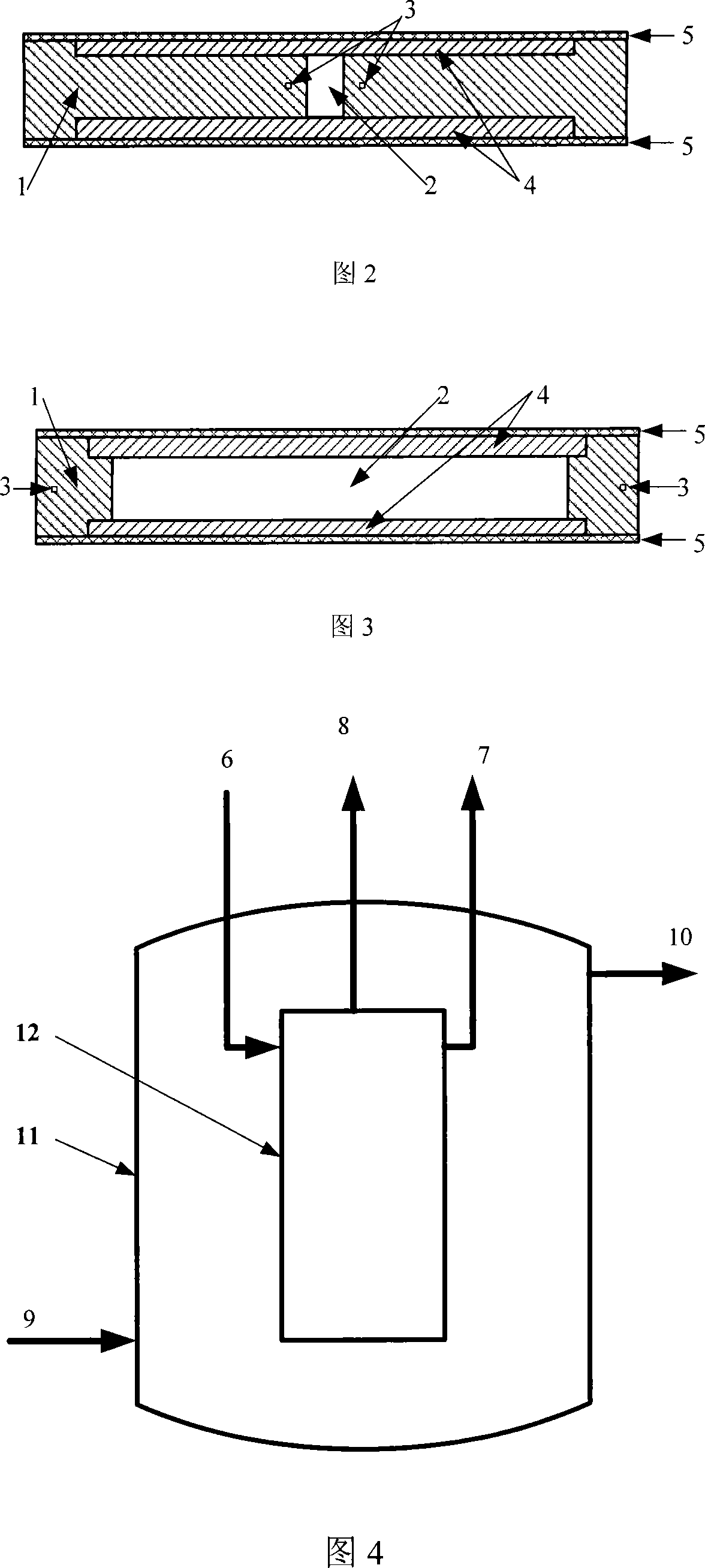

[0025] As shown in Figure 1-3, a quick-start palladium membrane module using small-scale channels for heat transfer includes a membrane support frame 1, a porous metal support 4 and a palladium alloy membrane 5, two porous metal supports 4 and a palladium alloy membrane 5 are respectively located on both sides of the membrane supporting frame 1, the membrane supporting frame 1 contains the purified hydrogen gas flow channel 2 and the small-scale channel 3, the small-scale channel 3 is a heating gas passing through the membrane supporting frame 1 The circulation channel, its cross-section is rectangular, the cross-sectional size is 0.2-1.0 mm × 0.2-1.0 mm, and the channel inlet 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com