Method for preparing metallic silicon material

A technology of metal silicon and equipment, applied in the field of metal silicon material engineering, can solve the problems of high cost of producing polysilicon raw materials, restricting the popular use of solar cells, and high energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

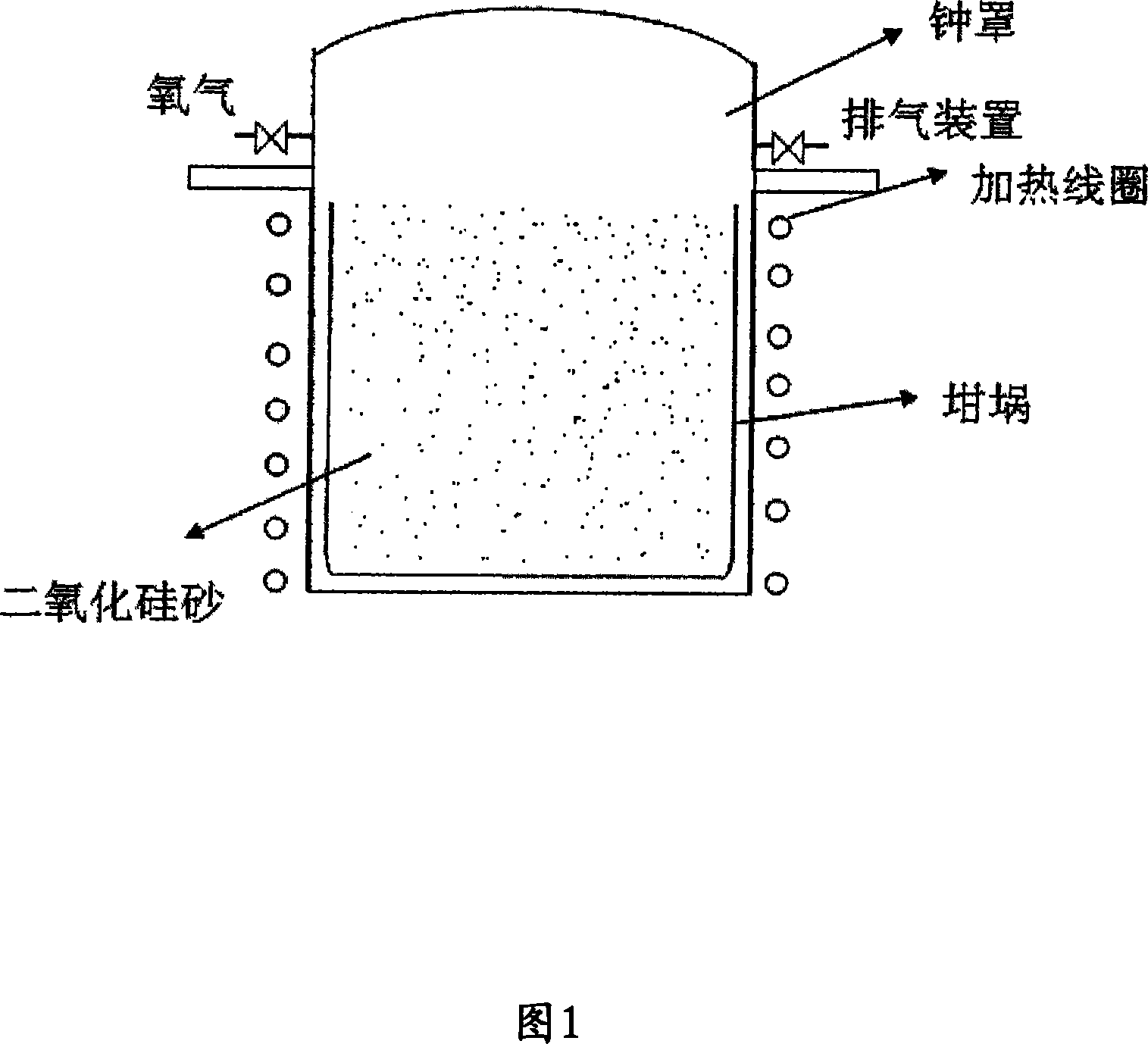

[0062] Install airtight pipe joints for oxygenation and pipe joints for exhaust gas on the bell jar of conventional electric arc furnaces, install inlet valves and oxygenation pipes on the pipe joints for oxygenation, and install airtight pipe joints for exhaust gas Exhaust valve and exhaust pipe are installed on the pipe joint, can obtain the smelting furnace of the present invention, its structure is specifically seen accompanying drawing 1.

Embodiment 2

[0064] The quartz ore silica with a purity of 99.5% is selected for pickling first. Specifically: the proportioning component is 3HCl: HNO 3 aqua regia to wash away heavy metals, metal ions and / or metal compounds, etc. Then, the phosphorous and boron compounds were washed away with an HF solution [50 parts of pure water: 1 part of HF (49%)]. After testing, the cleaned silicon dioxide (SiO 2 ), from 99.5% to 99.9%. Then use the freeze vacuum drying method to dry to make the water content <1%.

[0065] The quartz ore silica through the above operations is charged into the melting furnace of the present invention. Oxygen injection starts when the melting furnace reaches 600°C, and the oxygen injected is 98% O 2 , the furnace temperature is gradually raised to 1300°C at 10°C per minute to completely oxidize the phosphorus and boron in the silica ore to form phosphorus and boron oxide-P 2 o 5 / B 2 o 3 .

[0066] After the phosphorus boron is completely oxidized, stop the ...

Embodiment 3

[0070] Choose quartz ore silica with a purity of more than 99%, crush the quartz sand to the micron level, and then pickle it. Specifically: the proportioning component is 3HCl: HNO 3 aqua regia to wash away heavy metals, metal ions and / or metal compounds, etc. Then, the phosphorous and boron compounds were washed away with an HF solution [50 parts of pure water: 1 part of HF (49%)]. After testing, the cleaned silicon dioxide (SiO 2 ), from 99.% to 99.9%. Then use the centrifuge dehydration drying method to dry to make the water content <1%.

[0071] The quartz ore silica through the above operations is charged into the melting furnace of the present invention. Oxygen injection starts when the melting furnace reaches 600°C, and the oxygen injected is 98% O 2 , the furnace temperature gradually rises to 1300°C to completely oxidize the phosphorus and boron in the silica ore to form phosphorus and boron oxide-P 2 o 5 / B 2 o 3 .

[0072] After the phosphorus boron is co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap