Method of producing magnetic microsphere with surface functional group

A technology of surface functional groups and magnetic microspheres, applied in the field of composite materials, can solve problems such as limiting applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Take 10ml styrene, 0.79g polyvinylpyrrolidone (PVP K30), 0.099g azobisisobutyronitrile, 0.095g magnetic Fe 3 o 4 Add 50ml of ethanol solution and 6ml of deionized water into the three-necked flask, and ultrasonically disperse them evenly. Then nitrogen gas (N 2 ) to deoxygenate for 5 minutes, and under the action of stirring (120 rpm), the reaction temperature was raised to 70° C. for 24 hours. After the reaction is completed, the mixed solution is first subjected to magnetic separation using ethanol as a solvent for 3-5 times, and the supernatant is removed; then, it is dispersed and magnetically separated for 3-5 times with deionized water, and finally the obtained magnetic precipitate is lyophilized and stored.

[0019] Take 2 g of the above magnetic microspheres, add 66.7ml of 98% concentrated sulfuric acid, and disperse the microspheres evenly with ultrasound. Then the mixed solution was heated to 50° C. and reacted for 6 h under the condition of magnetic stirri...

Embodiment 2

[0022] Take 4ml styrene, 2.5ml acrylic acid, 0.4g polyvinylpyrrolidone (PVP K30), 0.032g azobisisoheptanonitrile, 0.0325g magnetic Fe 3 o 4 Add 56ml of ethanol solution into the three-necked flask, and ultrasonically disperse it evenly. Then nitrogen gas (N 2 ) to deoxygenate for 15 minutes, and under the action of stirring (80 rpm), the reaction temperature was raised to 75° C. for 12 hours. After the reaction is completed, the mixed solution is first subjected to magnetic separation using ethanol as a solvent for 3-4 times, and the supernatant is removed; then, magnetic separation is performed 3-4 times with deionized water.

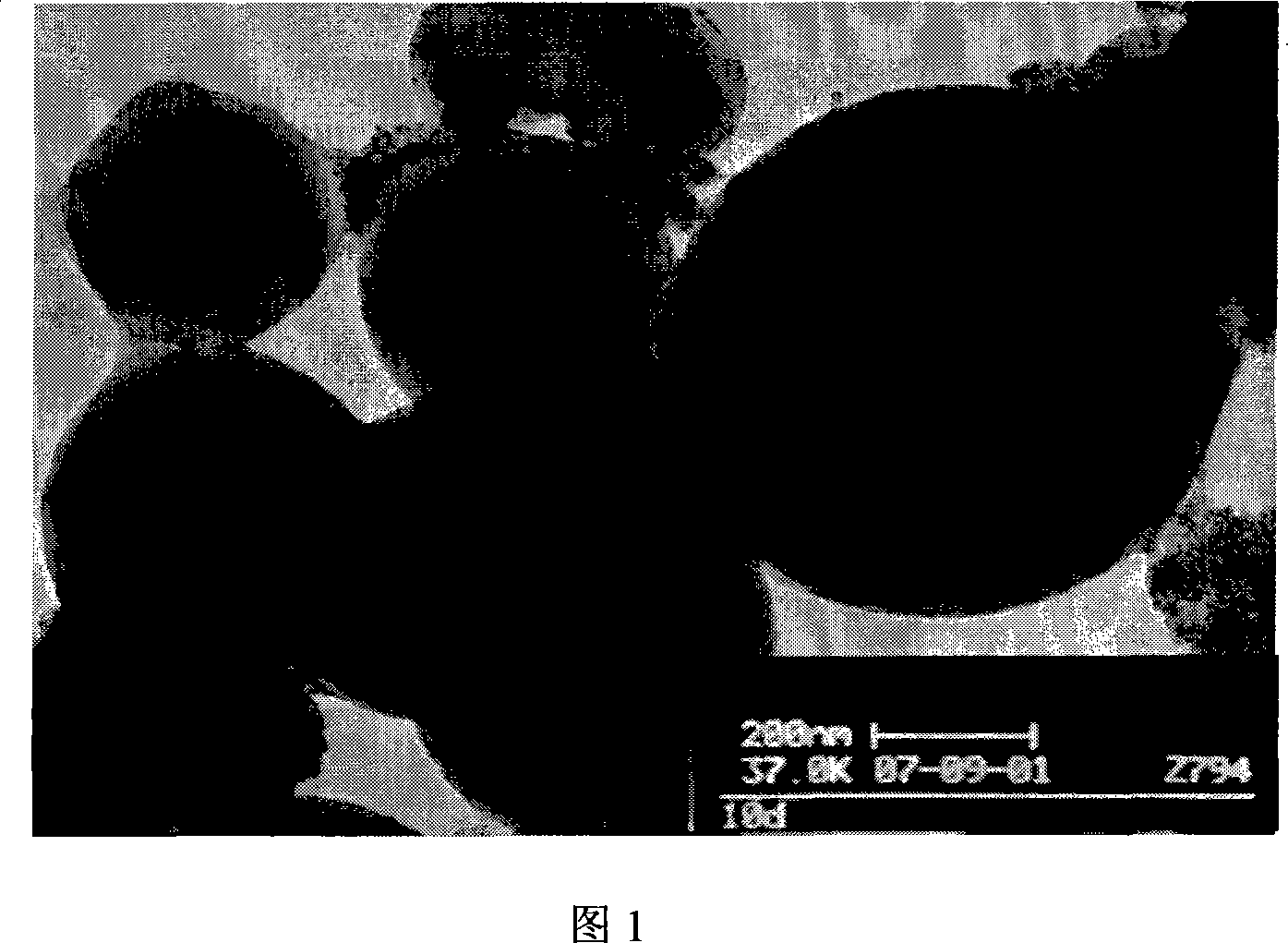

[0023] The particle size of the magnetic microspheres prepared by the above reaction is about 650nm observed by scanning electron microscope, and it can be observed by transmission electron microscope that the inside of the microspheres contains a plurality of magnetic nanoparticles. Using a vibrating sample magnetometer to test the obtained magneti...

Embodiment 3

[0025] Take 1 g of the magnetic microspheres prepared in Example 2, add 20 ml of 98% concentrated sulfuric acid, and disperse the microspheres evenly with ultrasound. Then react at room temperature (25° C.) for 6 h under the condition of magnetic stirring. After the reaction is complete, freeze the mixed solution and add deionized water for magnetic separation, remove the supernatant after separation, and add deionized water again, repeat the above process 8-10 times. The precipitate was freeze-dried for later use.

[0026] The particle size of the magnetic microspheres prepared by the above reaction is about 650nm observed by scanning electron microscope, and it can be observed by transmission electron microscope that the inside of the microspheres contains a plurality of magnetic nanoparticles. Using a vibrating sample magnetometer to test the obtained magnetic microspheres, the saturation magnetization can reach 18emu / g. Microspheres with sulfonate groups, carboxyl groups...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com