Unsymmetrical network shape pore structure hollow fiber film and preparation method thereof

A fiber membrane and network technology, applied in the production field of hollow fiber membrane, can solve the problems of high working pressure, low membrane flux, membrane damage, etc., and achieve the effect of increasing pore size, uniform membrane formation, and increasing dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

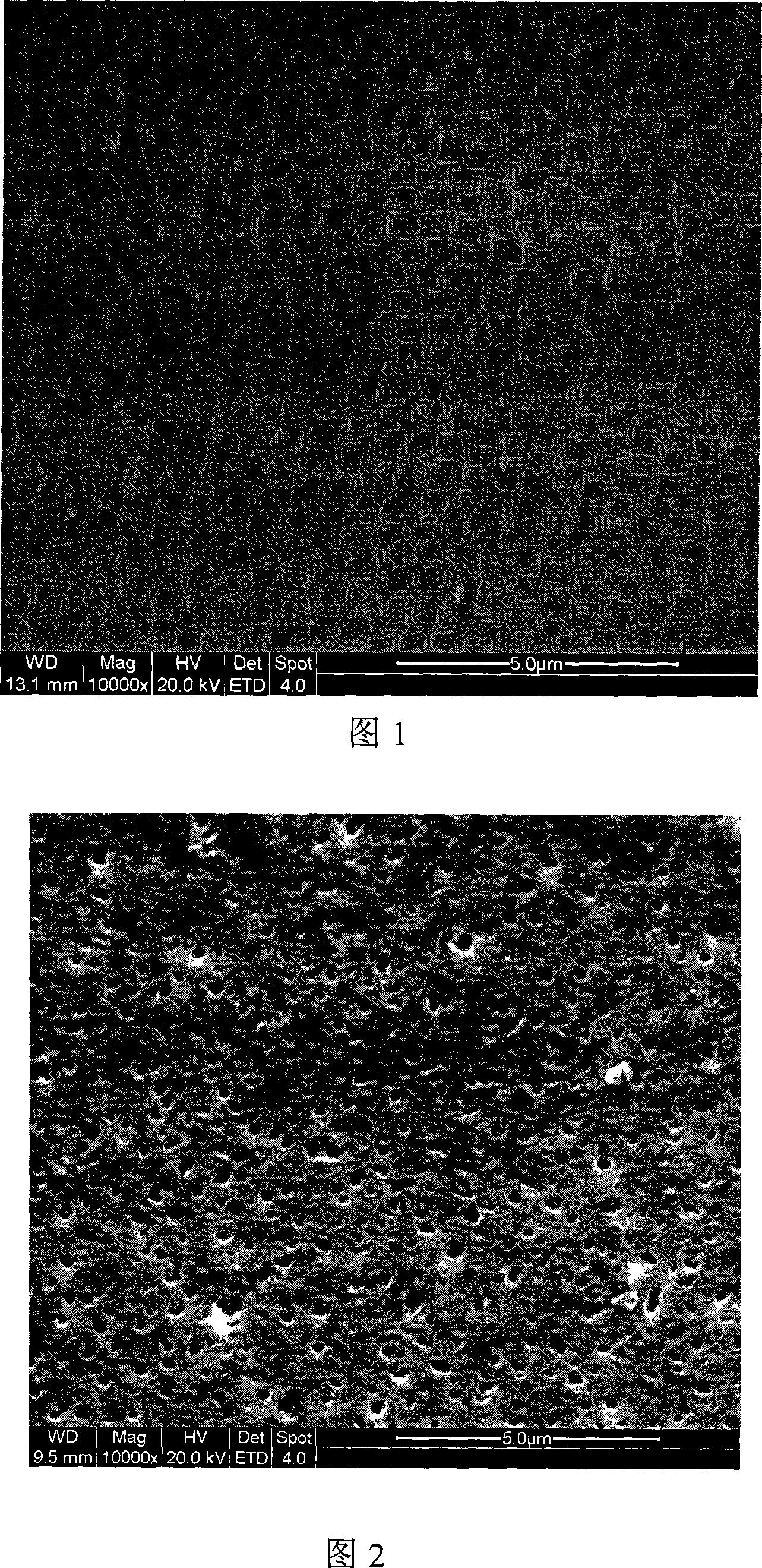

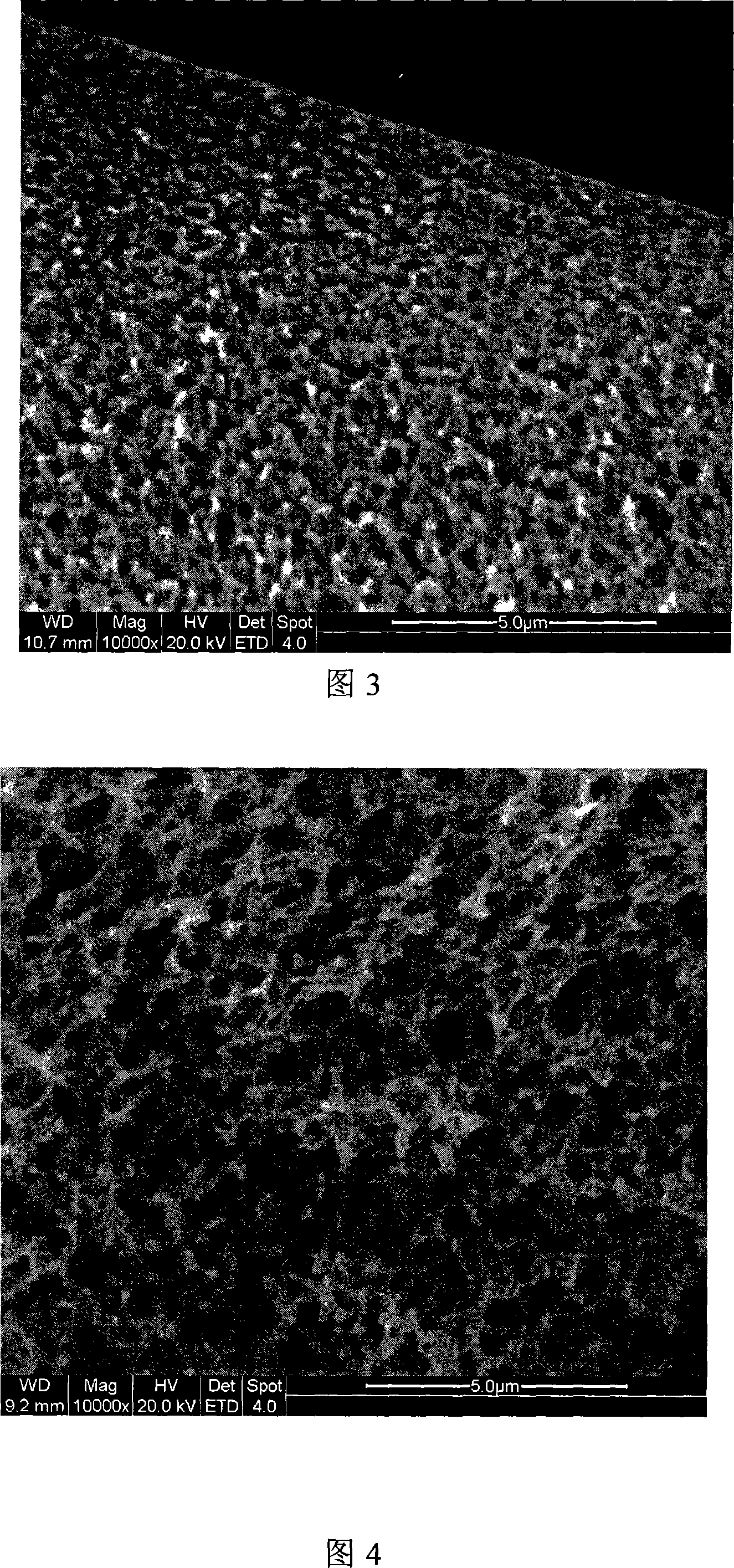

Embodiment 1

[0031] Embodiment 1: polysulfone ether 21%, diethylene glycol 45%, N-N dimethylpyrrolidone (NMP) 34%, mix uniformly at 50 ℃, stand at 50 ℃ for vacuum defoaming for 24 hours, spin The raw liquid is transported to the A-type spinneret, the coagulation bath is water, and the core liquid is water. Control the spinning speed to 15m / min, wash the membrane silk with clean water, and after heat treatment, the inner diameter is 0.8mm, the outer diameter is 1.3mm, the test retention rate of ovalbumin solution is 97.5%, and the pure water flux is 400L / m 2 .h(0.1MPa). The average pore diameter of the outer layer of the membrane is 250 μm (SEM method). The support layer is a network of through holes. The average pore diameter of the inner surface layer is 25nm (AFM method).

Embodiment 2

[0032] Embodiment 2: polysulfone ether (Amoco) 19%, diethylene glycol (Mitsubishi Corporation of Japan) 46%, N-N dimethylpyrrolidone (NMP) 34%, mix uniformly at 50 ℃, stand vacuum at 50 ℃ After defoaming for 24 hours, the spinning dope is transported to the B-type spinneret, the coagulation bath is water, and the core liquid is a mixed solution of water and NMP. Control the spinning speed at 15m / min, wash with water and heat-treat to obtain an inner diameter of 1.1mm, an outer diameter of 1.6mm, a bovine serum albumin solution test rejection rate of 97.0%, and a pure water flux of 550L / m 2.h(0.1MPa). The average pore diameter of the outer layer of the membrane is 250 μm (SEM method), and the support layer is a network of through holes.

Embodiment 3

[0033] Embodiment 3: 20% of polysulfone ether, 46% of diethylene glycol, 34% of N-N dimethylpyrrolidone (NMP), mixed uniformly at 50°C, left standing at 50°C for vacuum defoaming for 24 hours, spinning The raw liquid is sent to the B-type spinneret, the coagulation bath is water, and the core liquid is water. Control the spinning speed to 15m / min, wash with water, and after heat treatment, the inner diameter is 1.1mm, the outer diameter is 1.6mm, the retention rate of ovalbumin solution is 96.5%, and the pure water flux is 450L / m 2 .h(0.1MPa). The average pore diameter of the outer layer of the membrane is 250 μm (SEM method), and the support layer is a network of through holes. The average pore diameter of the inner surface layer is 25nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com