Method for separating metallicity and semiconductivity nano-tube from single wall carbon nano-tube

A single-wall carbon nanotube and metal separation technology, which is applied in the field of carbon nanotubes, achieves low cost, improved dispersion, and is conducive to large-scale applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

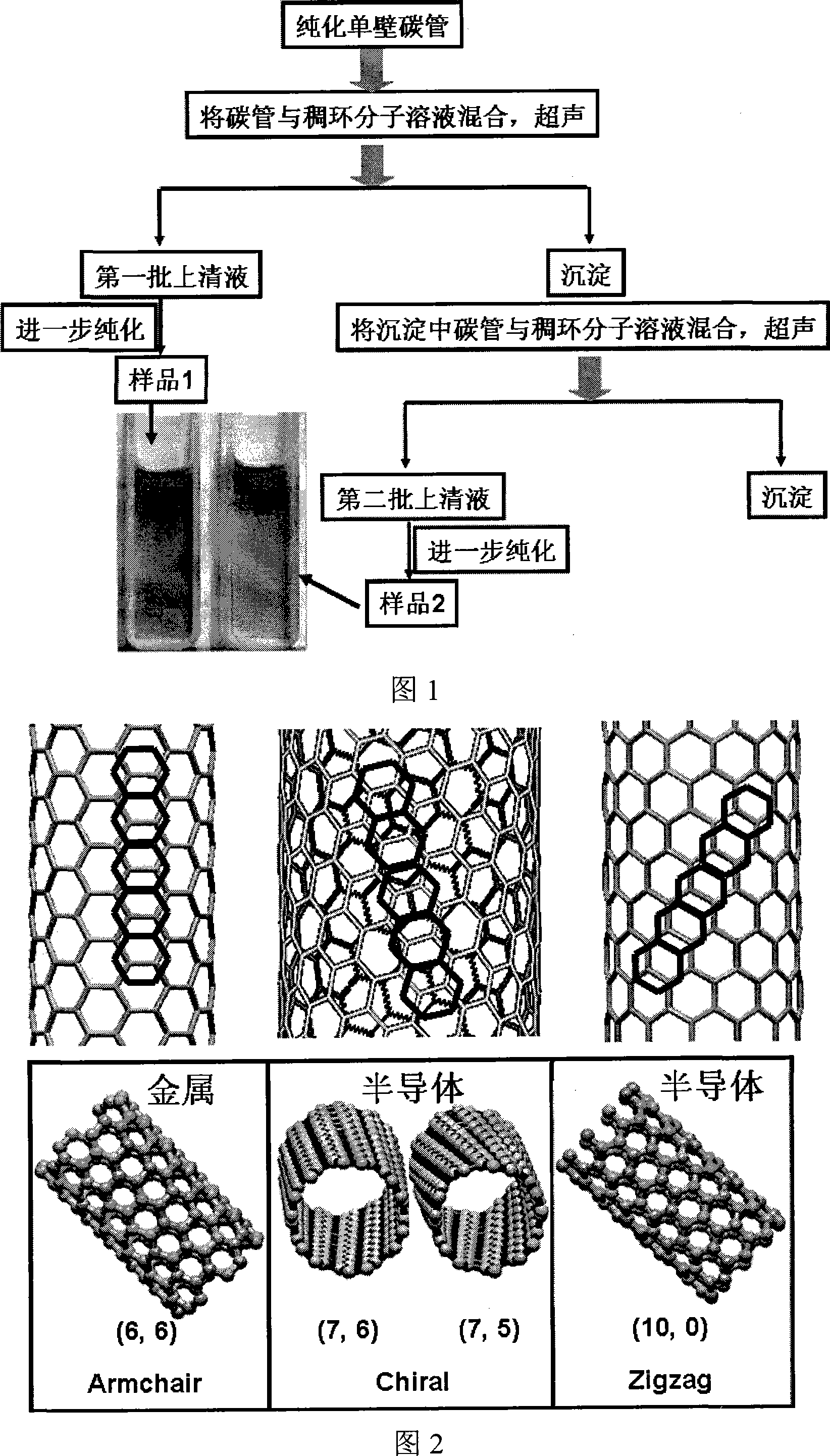

Method used

Image

Examples

Embodiment 1

[0034] Implementation Example 1 : Purification of carbon tubes

[0035] Since the carbon tube powder used in the experiment has certain impurities, it is necessary to carry out pretreatment, that is, purification treatment, which can make the subsequent separation more effective and reliable. If the carbon tube powder used is relatively pure, the purification treatment in this embodiment may not be used.

[0036] The purification treatment method used in the present embodiment is: first, 1 weight part of carbon nanotubes is added to 10 weight parts of concentrated hydrochloric acid solution of 4 weight parts of sodium lauryl sulfate or sodium dodecyl sulfate, ultrasonic 3 After ~4h, let it stand still, pour out the upper layer of acid solution after the carbon tubes are precipitated, and then add new acid solution with surfactant to sonicate, in order to fully remove the catalyst particles in the carbon nanotubes, repeat this step until the acid solution The solution no long...

Embodiment 2

[0037] Implementation Example 2 : Polycyclic aromatic hydrocarbon compound-6,13-bis(2-(trimethylsilyl)ethynyl)pentacene is modified and the first step of separation product

[0038] 1 part by weight of the purified single-walled carbon nanotubes obtained in Example 1, and 0.09 parts by weight of 6,13-bis(2-(trimethylsilyl)ethynyl)pentacene in N-methylpyrrolidone 200W After mixing and ultrasonicating at high power for 3.5 hours, centrifuge at a speed of 12,000 rpm in a high-speed centrifuge to collect the supernatant and precipitate. Filter the supernatant and precipitate with a 0.22 micron microporous membrane, wash with a large amount of solvent to remove a small amount of unadsorbed or desorbed 6,13-bis(2-(trimethylsilyl)ethynyl)pentacene. The product on the filter was collected to obtain the supernatant and precipitate from the first separation. The supernatant was filtered with glass wool, and the filtrate was collected to obtain sample 1.

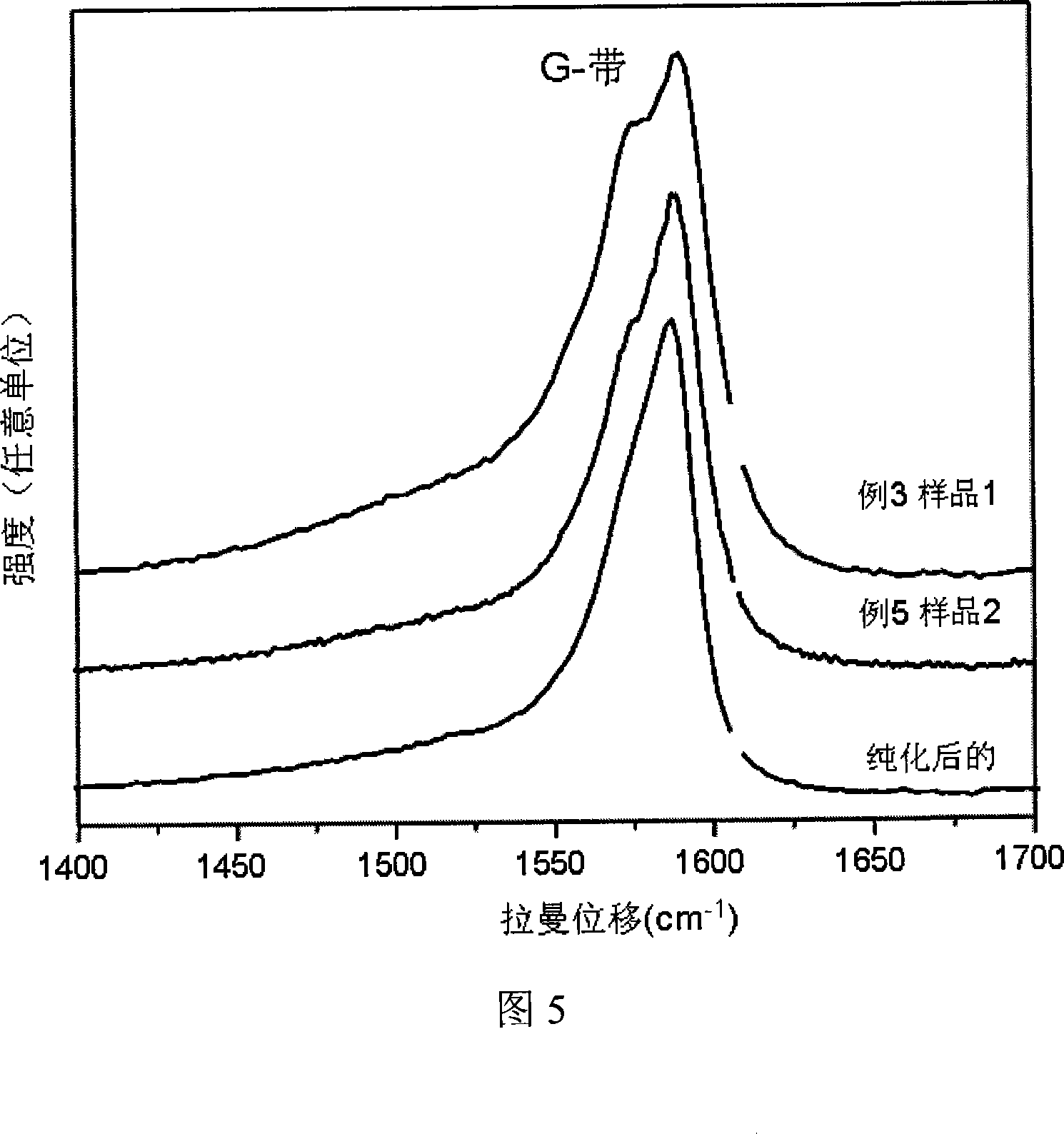

[0039] The characterization...

Embodiment 3

[0040] Implementation Example 3 : Modification of fused-ring aromatic compound-anthracene and the first product separation

[0041] Mix 1 part by weight of the purified single-walled carbon nanotubes obtained in Example 1 with 0.1 part by weight of anthracene in chloroform at a power of 200 W and sonicate for 3.5 hours, centrifuge at a speed of 12000 rpm in a high-speed centrifuge, and collect the supernatant and precipitate respectively. Filter the supernatant and precipitate with a 0.22 micron microporous membrane, and wash with a large amount of solvent to remove a small amount of unadsorbed or desorbed anthracene. The product on the filter was collected to obtain the supernatant and precipitate from the first separation. The supernatant was filtered with glass wool, and the filtrate was collected to obtain sample 1.

[0042] The characterization of the isolated product is shown in Figure 3, Figure 4 and Figure 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com