Method for preparing particle diameter homogeneous polysilicon oxide microsphere with active group

An active and oxide technology, applied in the field of chemistry and materials, can solve the problems of poor reproducibility, non-uniform particles, difficult to apply to the production field, etc., to achieve the effect of simple operation, short production cycle and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

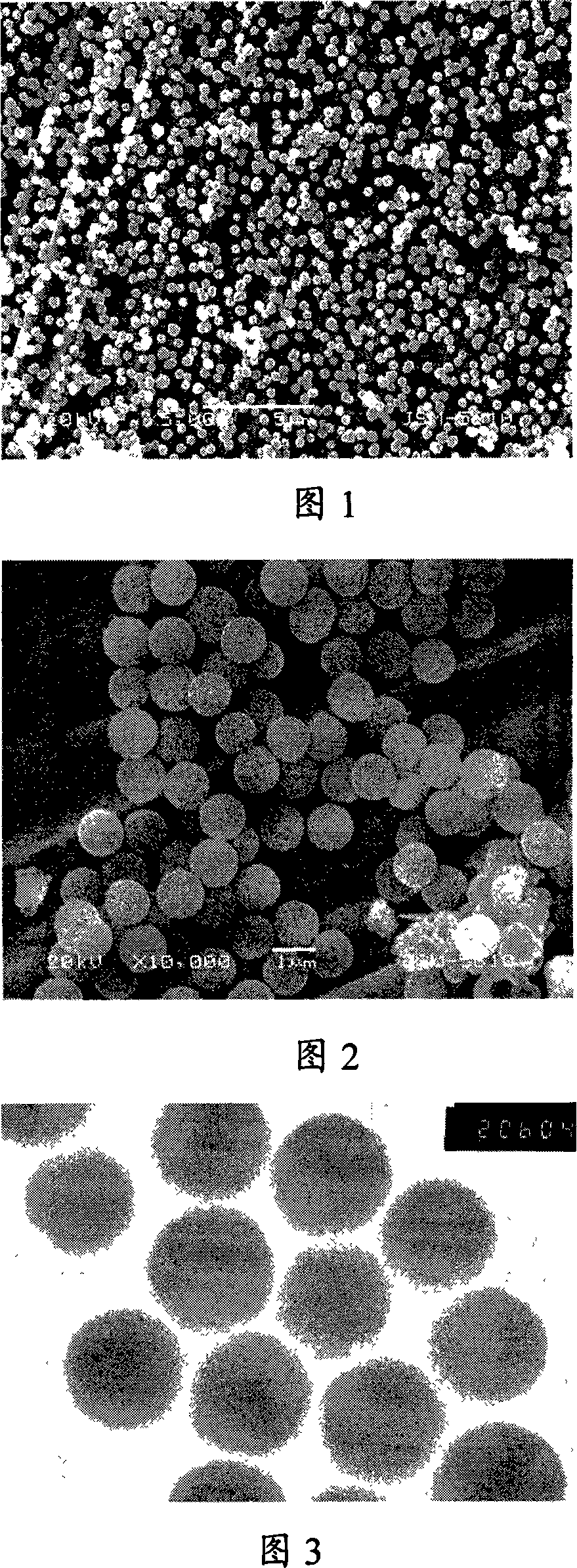

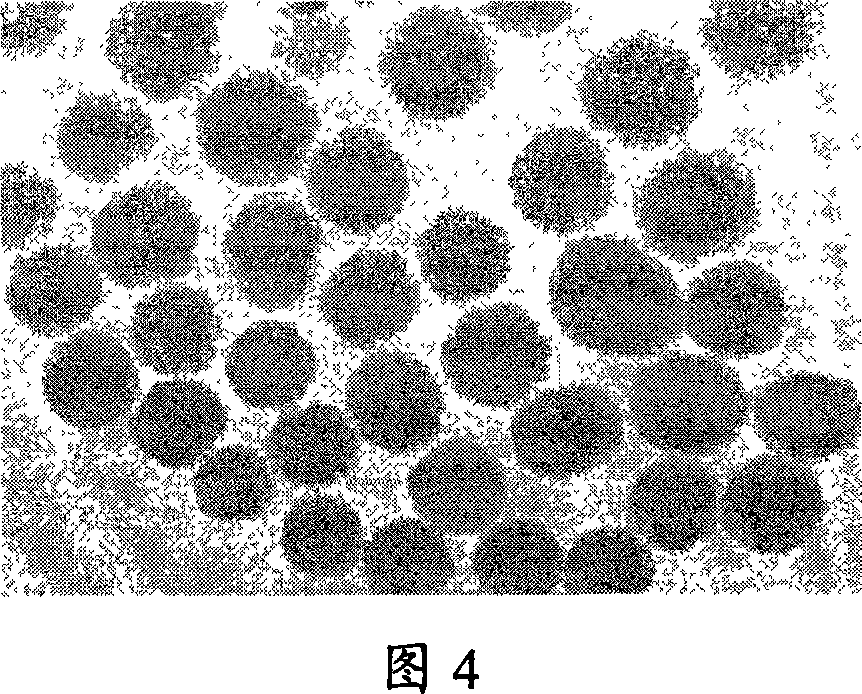

[0031] Add 500 moles of absolute ethanol and 2.5 liters of 30% ammonia water in proportion to the polytetrafluoroethylene liner reactor, and stir for 5 minutes at room temperature. Mix 10 moles of ethyl orthosilicate and 15 moles of n-octyltriethoxysilane at room temperature, and then slowly add them from the feeding port to the above-mentioned reactor and stir and mix at a speed of 300 rpm to make the mixture evenly mixed. The reaction is uniform. The reaction temperature is controlled at about 25°C for a constant temperature reaction for about 5 hours.

[0032] After the reaction is completed, the mixture in the kettle is filtered and washed with deionized water for 2 to 3 times. The solid particles are washed with toluene or tetrahydrofuran for 2 to 3 times. The resulting filter cake is dried in an oven at 100°C for two hours to obtain a powder. It is octyl functionalized polysilicon oxide particles. The powder is placed in a muffle furnace at a constant temperature of about 30...

Embodiment 2

[0034] Add 500 moles of absolute ethanol and 2.5 liters of 30% ammonia water in proportion to the polytetrafluoroethylene liner reactor, and stir for 5 minutes at room temperature. Mix 10 moles of ethyl orthosilicate and 2 moles of aminopropyltriethoxysilane at room temperature, and then slowly add them to the above-mentioned reaction kettle from the feeding port and stir and mix at a speed of 300 rpm to make the mixture evenly mixed. The reaction is uniform. The reaction temperature is controlled at about 25°C for a constant temperature reaction for about 5 hours.

[0035] After the reaction is completed, the mixture in the kettle is filtered and washed with deionized water 2 to 3 times, and the solid particles are washed with toluene or tetrahydrofuran 2 to 3 times. The resulting filter cake is dried in an oven at 80°C for two hours to obtain a powder. It is an aminopropyl functionalized polysilicon oxide particle. The powder is placed in a muffle furnace at a constant temperatu...

Embodiment 3

[0037] Add 250 moles of absolute ethanol and 2.5 liters of 30% ammonia water in proportion to the reaction kettle with a polytetrafluoroethylene liner, and stir for 5 minutes at room temperature. Mix 5 moles of potassium silicate, 5 moles of ethyl orthosilicate and 5 moles of vinyl triethoxy silane at room temperature, and then slowly add them from the feed port to the above-mentioned reactor at 300 revolutions per minute. Stir and mix at speed to make the reaction uniform. The reaction temperature is controlled at about 25°C for a constant temperature reaction for about 5 hours.

[0038]After the reaction is completed, the mixture in the kettle is filtered and washed with deionized water for 2 to 3 times. The solid particles are washed with toluene or tetrahydrofuran for 2 to 3 times. The resulting filter cake is dried in an oven at 80°C for two hours to obtain a powder. It is vinyl functionalized polysilicon oxide particles. The powder is placed in a muffle furnace at a constant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com