Culture medium for increasing speed of nitrite oxidation by nitrobacteria

A technology for oxidizing nitrite and culture medium, applied in the field of culture medium to effectively increase the rate of nitrifying bacteria oxidizing nitrite, can solve problems such as economic loss, excessive accumulation of nitrite poisoning, lack of nitrifying bacteria products, etc., and achieve the degradation rate The effect of improving and speeding up the growth metabolism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

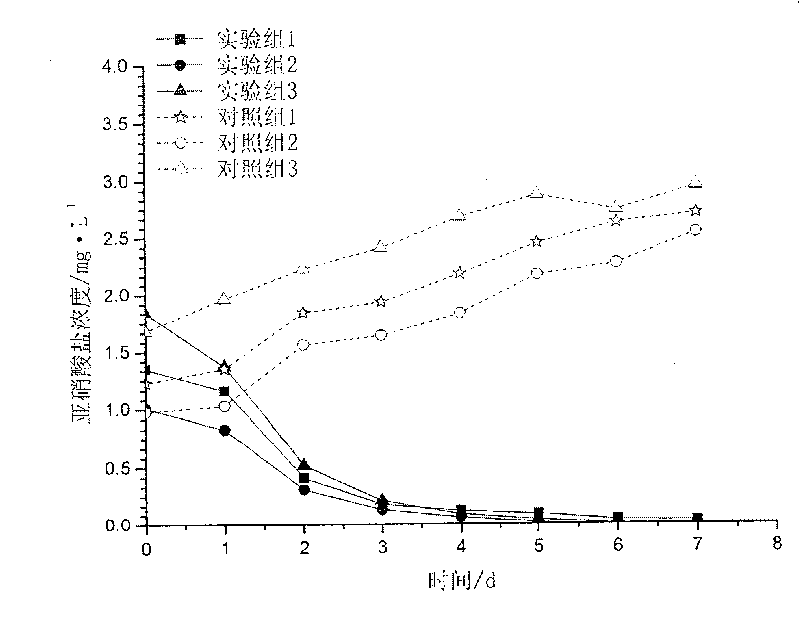

Embodiment 1

[0021] Dissolve 2.1 g of glycerin, 1.3 g of yeast extract, 1.0 g of sodium bicarbonate, 1.9 g of sodium nitrite, 0.1 g of sodium carbonate, 0.1 g of sodium chloride, 0.1 g of potassium dihydrogen phosphate, 0.1 g of magnesium sulfate, and 0.005 g of ferrous sulfate was used as a culture medium.

[0022] Nitrobacter strains (Nitrobacter hamburgensis, Nitrobacter winogradskyi, etc.) were activated and scaled up to 1L step by step, the temperature was 30°C, the dissolved oxygen was controlled to be greater than 5.0mgO2 / L, and an inoculum of 10% by volume was inserted into the above medium. The degradation rate of the cultivated bacterial agent was 926.4mgNO2-N / gMLSS·d. In the same batch, conventional medium was used (every 1000 mL of water contained 2.0 g / L of sodium bicarbonate, 0.5 g / L of sodium nitrite, 0.2 g / L of potassium dihydrogen phosphate, 0.05 g / L of magnesium sulfate, and 0.1 g / L of iron sulfate. ) to obtain a degradation rate of 580.0mgNO 2 -N / gMLSS·d. The results ...

Embodiment 2

[0024] Dissolve glycerin 3.1, yeast extract 1.9g, sodium bicarbonate 2.0g, sodium nitrite 3.2g, sodium carbonate 0.8g, sodium chloride 0.5g, potassium dihydrogen phosphate 0.5g, magnesium sulfate 0.5g and Ferrous sulfate 0.05g was made into culture medium. Nitrobacter strains (Nitrobacter hamburgensis, Nitrobacter winogradskyi, etc.) were activated and scaled up to 1L step by step, the temperature was 28°C, the dissolved oxygen was controlled to be greater than 5.0mgO2 / L, and the inoculum of 5% by volume was inserted into the above medium. The degradation rate of the cultivated bacterial agent was 947.8mgNO2-N / gMLSS·d. In the same batch, conventional medium was used (every 1000 mL of water contained 2.0 g / L of sodium bicarbonate, 0.5 g / L of sodium nitrite, 0.2 g / L of potassium dihydrogen phosphate, 0.05 g / L of magnesium sulfate, and 0.1 g / L of iron sulfate. ) to obtain a degradation rate of 580.0mgNO 2 -N / gMLSS·d. The result shows that the degradation rate of the nitrifying...

Embodiment 3

[0026] Dissolve 2.6g of glycerin, 1.6g of yeast extract, 1.7g of sodium bicarbonate, 2.7g of sodium nitrite, 0.5g of sodium carbonate, 0.4g of sodium chloride, 0.4g of potassium dihydrogen phosphate, and 0.2g of magnesium sulfate in 1000mL of water. and ferrous sulfate 0.01g to make culture medium. Activate the nitrifying bacteria (Nitrobacter hamburgensis, Nitrobacter winogradskyi, etc.) and scale up to 1L step by step. The temperature is 32°C, the dissolved oxygen is controlled to be greater than 5.0mg / L, and the inoculum of 8% by volume is inserted into the above medium. The degradation rate of the cultivated bacterial agent was 1194.1mgNO2-N / gMLSS·d. In the same batch, conventional medium was used (every 1000 mL of water contained 2.0 g / L of sodium bicarbonate, 0.5 g / L of sodium nitrite, 0.2 g / L of potassium dihydrogen phosphate, 0.05 g / L of magnesium sulfate, and 0.1 g / L of iron sulfate. ) to obtain a degradation rate of 580.0mgNO 2 -N / gMLSS·d. The results show that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com