A micro -bubble cultivation harvesting microalgae biofilm reactor and its microalona culture harvesting method

A technology of micro-nano bubbles and micro-algae organisms, applied in photobioreactors, methods of supporting/immobilizing microorganisms, bioreactor/fermenter combinations, etc. Difficulty in harvesting algae and other problems, to achieve the effect of reducing hydraulic retention time, increasing growth rate, and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

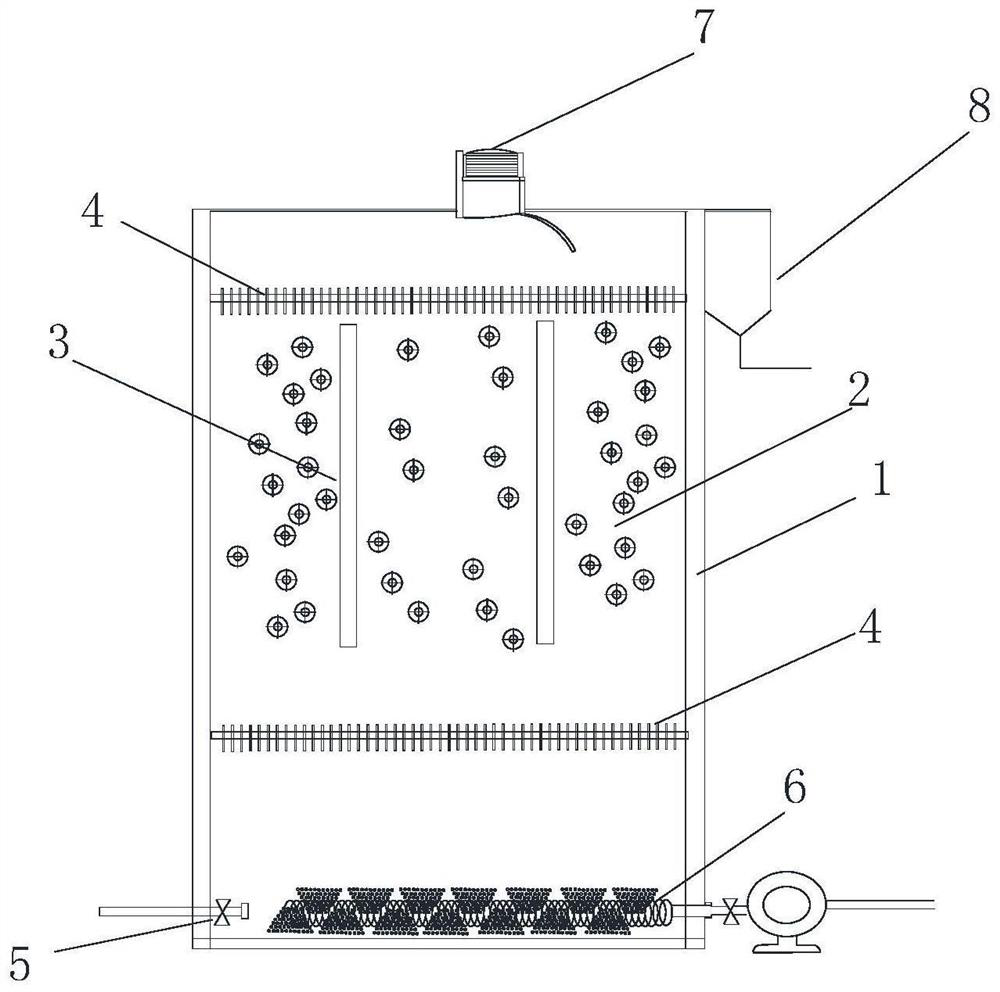

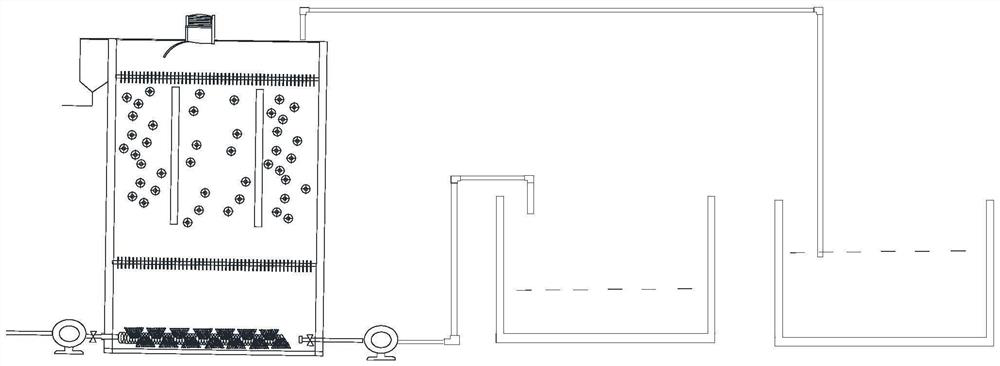

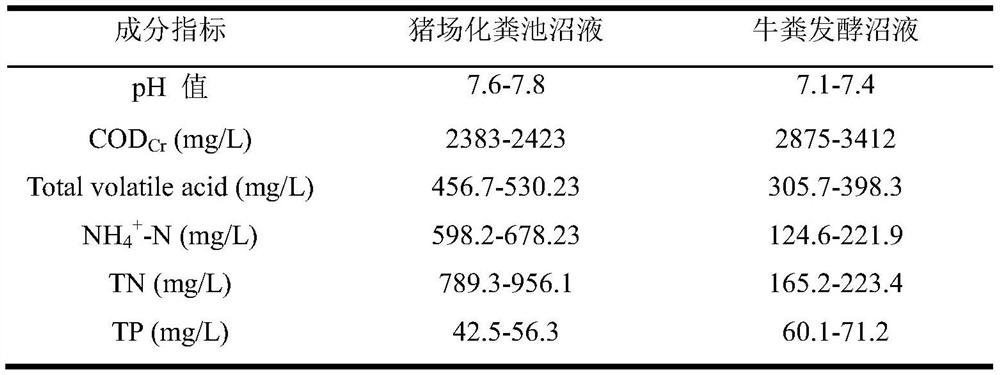

[0032] like figure 2 As shown, the pig farm septic tank biogas slurry was used to cultivate Chlorella vulgaris. Algae cultivation stage: biogas slurry enters the reaction tank, micro-nano aeration membrane module parameters (bubble diameter is 0.1 ~ 50 microns, aeration volume is 0.15 ~ 0.2L / min), light intensity parameters (3500 ~ 6500lux, light-dark time ratio 12h:12h). When the microalgae biofilm reaches the stable growth stage, the hydraulic retention time is 4 to 6 days, the concentration of microalgae in the reactor reaches 5 to 6.5 g / L, and the removal rates of dissolved organic matter, total nitrogen and total phosphorus in the wastewater are 75.04 to 75.04 g / L, respectively. 85.54%, 82.10~86.43% and 95.23%~97.05%. Microalgae harvesting stage: adjust the parameters of the micro-nano aeration membrane module (the diameter of the bubbles is 10-30 microns, and the air flotation time is 5-10 minutes), and the concentrated algae liquid collected by the algae scraper by s...

Embodiment 2

[0034] like figure 2 As shown, the cow dung fermented biogas slurry was used to cultivate Chlorella vulgaris. Algae cultivation stage: biogas slurry enters the reaction tank, micro-nano aeration membrane module parameters (bubble diameter is 0.1 ~ 50 microns, aeration volume is 0.15 ~ 0.2L / min), light intensity parameters (3500 ~ 6500lux, light-dark time ratio 12h:12h). When the microalgae biofilm reaches the stable growth stage, the hydraulic retention time is 5 to 7 days, the concentration of microalgae in the reactor can reach 4.5 to 5.5 g / L, and the removal rates of dissolved organic matter, total nitrogen and total phosphorus in the wastewater are 65.40 ~75.50%, 75.50~85.50% and 85.50~95.50%. Microalgae harvesting stage: adjust the parameters of the micro-nano aeration membrane module (the diameter of the bubbles is 10-30 microns, and the air flotation time is 5-10 minutes), and the concentrated algae liquid collected by the algae scraper by scouring the air-floating m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com