LED lamp plate structure with patch type bracket and its production process

A technology of LED light board and production process, which is applied to the parts of lighting devices, semiconductor devices of light-emitting elements, lighting and heating equipment, etc., and can solve the problems of aging of phosphor powder, deterioration of color temperature stability of white light diodes, heat dissipation area of bracket 1 Limited and other problems, to achieve the effect of good color temperature consistency, excellent heat dissipation effect, and excellent product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

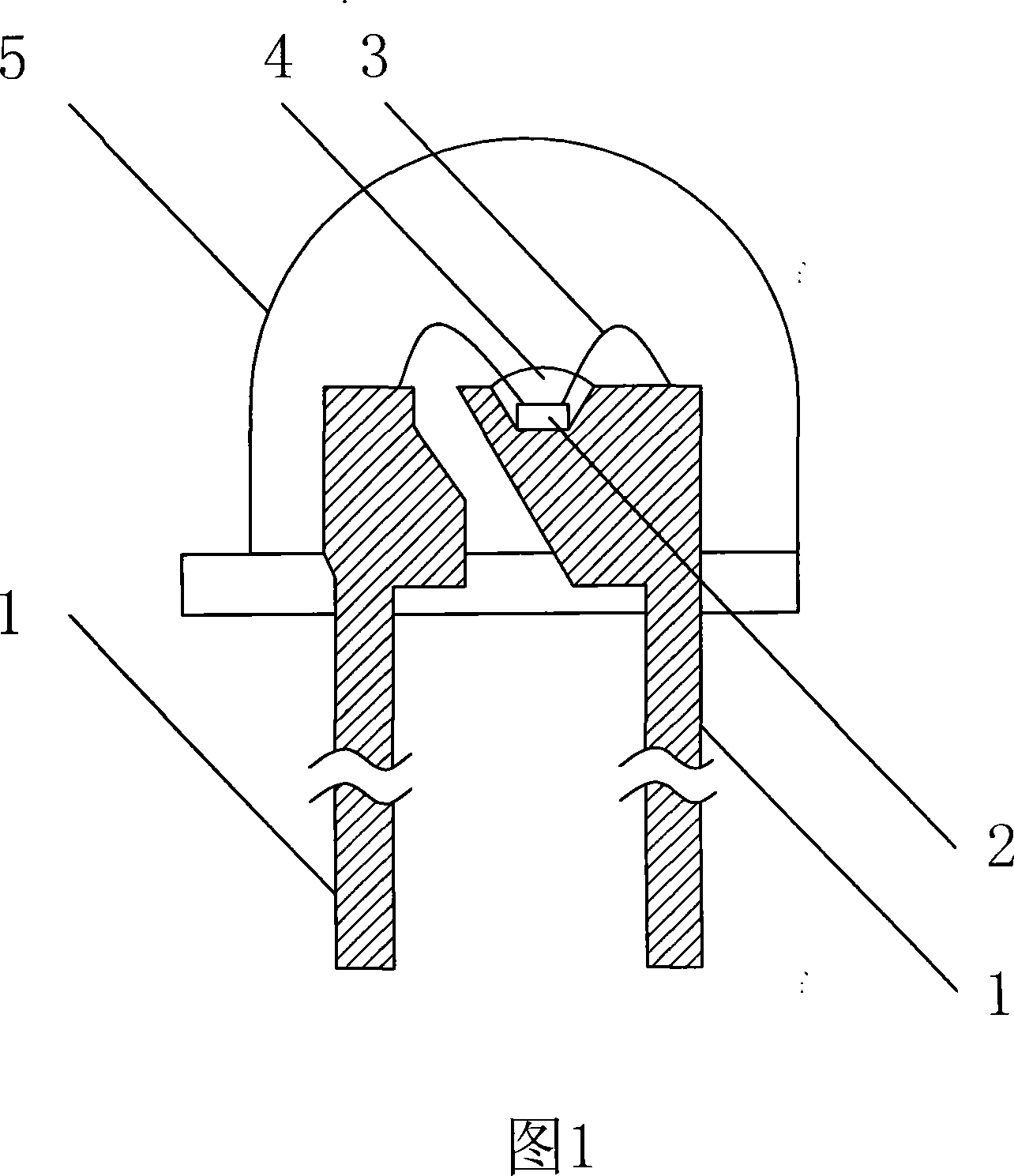

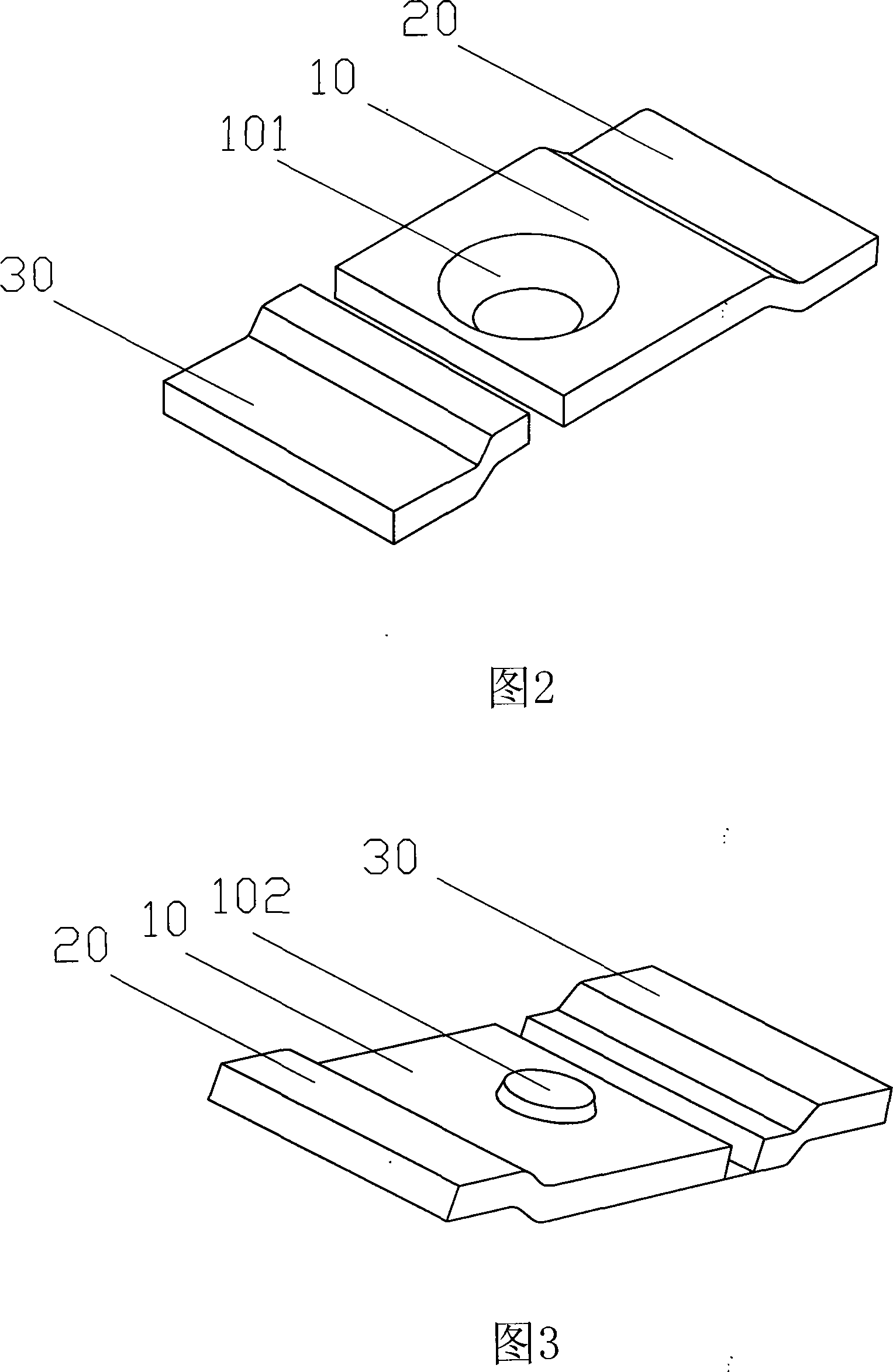

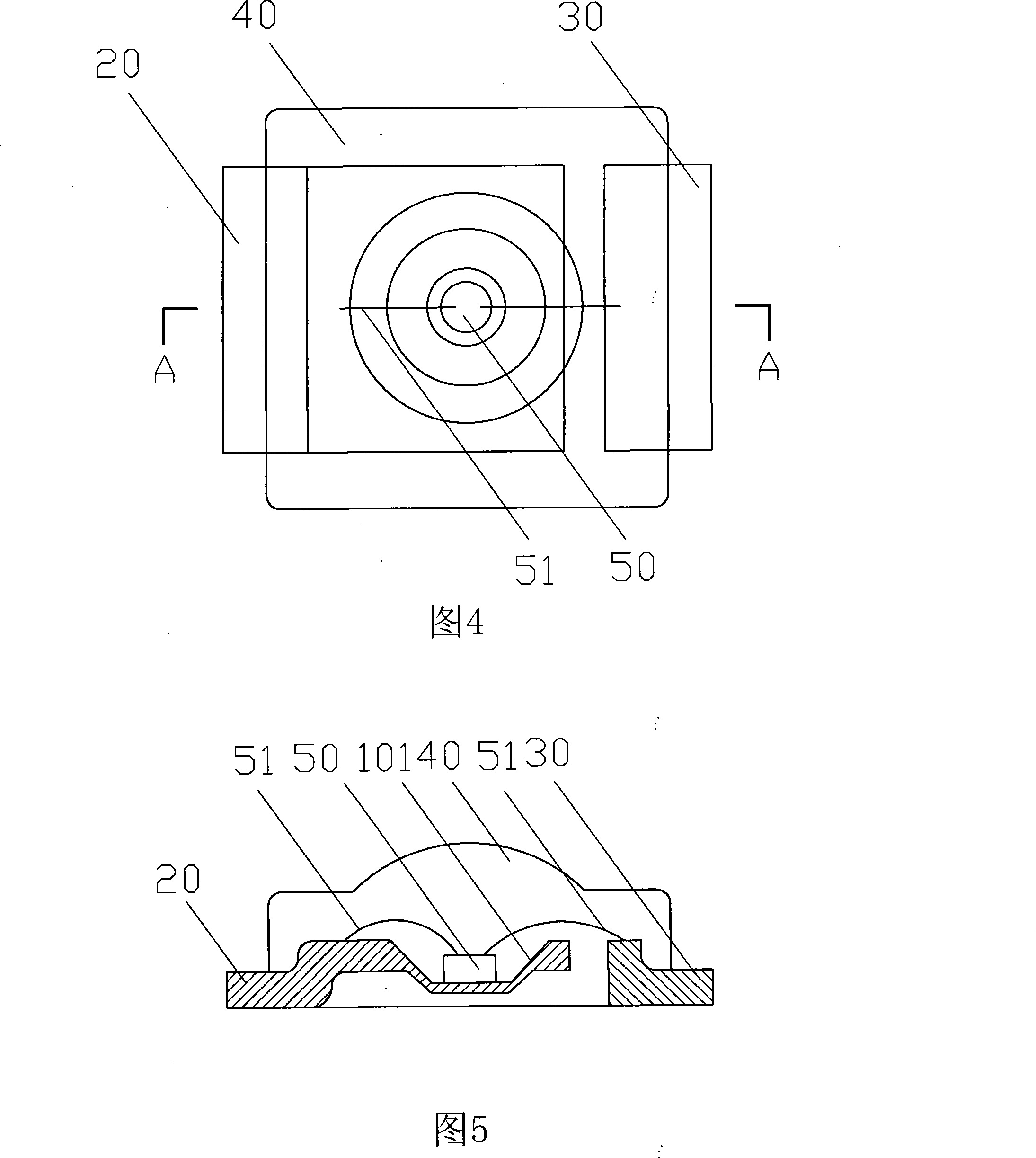

[0054]Embodiment 1: Refer to Fig. 2-5, Fig. 15-16: LED lamp board structure and its production process with patch bracket, which is characterized in that two metal plates that are not electrically connected to each other are used as the positive and negative poles of the LED lamp The connection terminals 20, 30 are arranged in the same plane, and a cup-shaped groove 101 is punched in the center on one of the pole plates 20, and the LED chip 50 is arranged in the middle of the groove 101, and the positive and negative poles 51 of the LED chip 50 They are respectively electrically connected to the metal plate terminals 20 and 30, and a solid or hollow transparent cover 40 is provided outside the LED chip 50, and a layer of phosphor powder may or may not be provided between the LED chip 50 and the transparent cover 40. After the LED chip 50 of the LED lamp is partially arranged in the center of the through hole 61 on the substrate 60, the positive and negative terminals 20, 30 of ...

Embodiment 2

[0066] Embodiment 2: Refer to Fig. 6-9, Fig. 17-18: the basic structure, production process and product use of this embodiment are the same as those of Embodiment 1, the difference is that each of the two metal plate terminals is connected 20 , 30 respectively extend to both sides to form a positive dual terminal 20 and a negative dual terminal 30. This structure is suitable for manufacturing medium-power or high-power LED lamps or lamp panels, because the positive dual terminal 20 and the negative dual terminal 30 are connected to the substrate. After 60 soldering, it is convenient to quickly dissipate the heat generated by the LED chip 50 in a larger amount during operation, so as to maintain a stable and long-term working state of the product.

Embodiment 3

[0067] Embodiment 3: Refer to Figures 10-14 and Figures 19-25: the basic structure, production process and product usage of this embodiment are the same as those of Embodiment 1, the difference is that a bottom of the cup-shaped groove 101 is punched into a Through hole 102, and both sides of through hole 102 are all set as bowl cup shape groove, like this, after LED chip 50 is packaged on the bowl cup shape groove 101 that has through hole 102, LED chip 50 is in groove 101 Both sides of the LED lamp can emit light, and can be made into a double-sided LED lamp 70 and an LED lamp board 80. This structure is a double-sided LED lamp 70 or LED lamp board 80 with large, medium and small power.

[0068] Extend each piece of terminal 20, 30 of the two metal plate terminals in Embodiment 3 to form a positive dual terminal 20 and a negative dual terminal 30 respectively, and then a medium-power or high-power LED lamp can be manufactured. 70 or LED light board 80.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com