Paint composition for preventing corrosion and process for forming an aluminum oxide coating layer using the same

A technology of aluminum oxide coating and steel structure, which is applied in the direction of anti-corrosion coating, metal material coating process, coating, etc., can solve problems such as cracks, stability deterioration, separation, etc., and achieve the effect of preventing corrosion and good stability

Inactive Publication Date: 2008-06-04

三株SMC株式会社

View PDF1 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, because it is an organic paint, although the initial effect is good, the deformation properties of the paint such as thermal expansion coefficient and ductility are greatly different compared with iron

Therefore, there is a problem with organic coatings that the formed coating is separated from the steel structure because the adhesion will gradually decrease over time

Especially epoxy paint, its problem is that it is difficult to apply to outdoor steel structures exposed to light for a long time, because the resin itself is easily decolorized under the action of ultraviolet rays contained in the exposed light

The problem with fluororesin coatings is that the elasticity of the contained rubber components decreases, causing cracks, and their stability gradually deteriorates

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

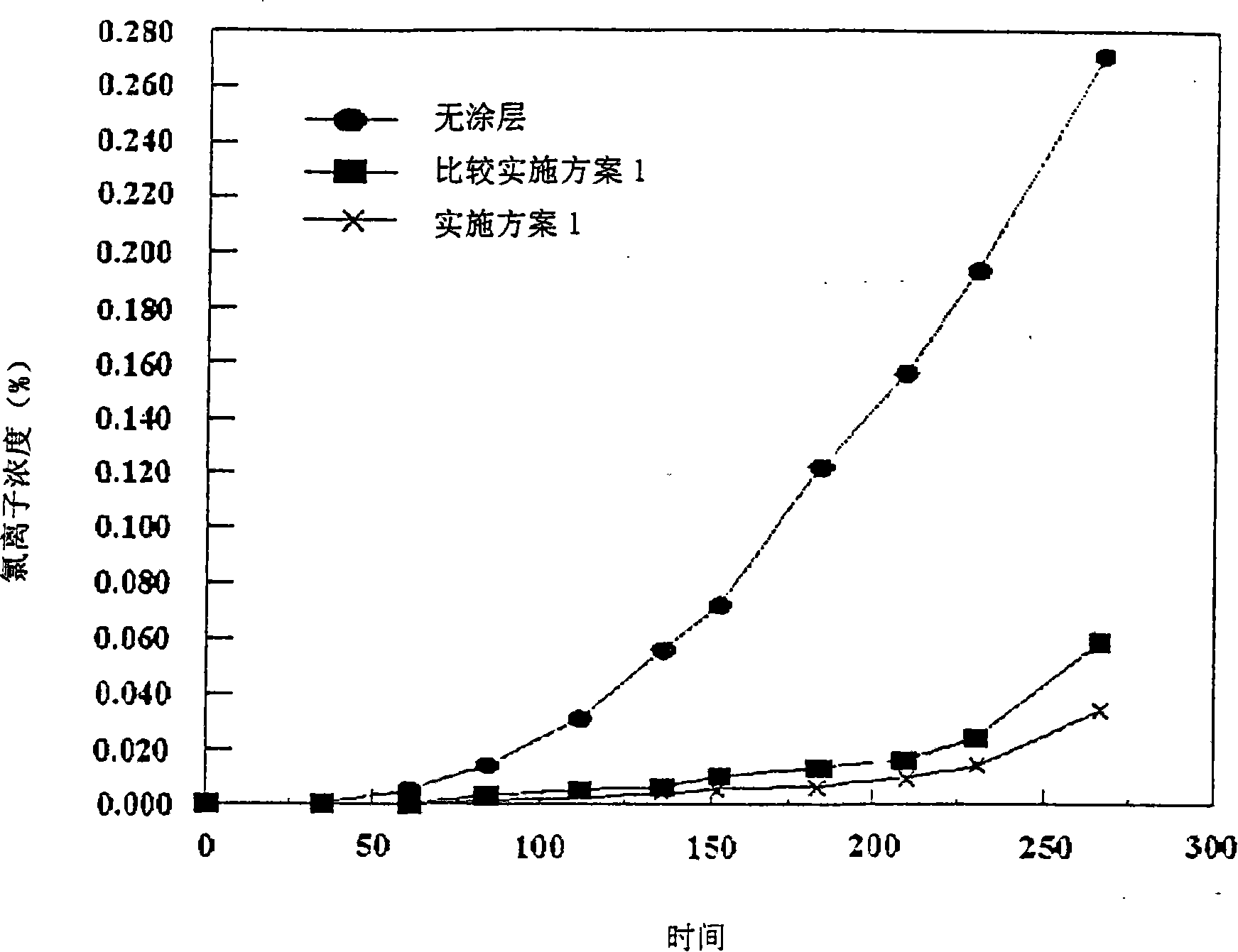

Embodiment approach 1

[0025] A powder mixture composed of 0.3% zinc powder, 0.5% chromium powder, 0.7% nickel powder, 0.1% phosphorus powder and 97.8% aluminum powder is mixed with polyurethane resin in a ratio of 1:10 to The spray method is sprayed on the surface of the target material, and then after a predetermined time at room temperature, the aluminum oxide coating with a thickness of 35D described in the present invention is formed.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The present invention relates to a coating composition that resists corrosion and enhances the long-term stability of steel structures, and a method of forming an aluminum oxide coating using the coating composition. The method for forming an aluminum oxide coating according to the present invention includes step (a) preparing zinc (Zn) powder, 0.3 to 1.0% chromium (Cr) powder, 0.5 to 1.0% zinc (Zn) powder, 0.5 to 1.0% A powder mixture of nickel (Ni) powder, 0.06 to 0.15% of phosphorus (P) powder and the remaining aluminum (Al) powder, and step (b) uniformly mixing the powder mixture prepared above with the binding resin, And the mixed mixture is evenly sprayed on the surface of the steel structure to form a coating. The method of forming the aluminum oxide coating according to the present invention is very economical and can be completed even at normal temperature. Therefore, by uniformly forming aluminum oxide coatings with good physical properties For example, the aluminum oxide coating on the surface of the steel structure, such as adhesion, ductility, elasticity, etc., can effectively prevent the steel structure from being corroded and enhance the long-term stability of the steel structure.

Description

technical field [0001] The present invention relates to a paint composition which resists corrosion and enhances the long-term stability of steel structures, including iron, and a method of forming an aluminum oxide coating using the paint composition. More specifically, a paint mixture capable of uniformly forming a corrosion-resistant alumina coating having good physical properties even at normal temperature, and a method of forming an alumina coating using the paint mixture. Background technique [0002] In general, most so-called steel structures including iron are exposed to corrosive environments such as air and the like. Therefore, people widely use the method of anti-corrosion treatment on the surface of steel structure to prevent corrosion. [0003] For example, a method has been studied by forming a coating on the surface of a steel structure with a paint such as epoxy paint, vinyl paint, fluororesin paint, acrylic paint, chlorinated rubber paint, or the like. Ho...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C23C24/00C09D5/10C23C24/08C23C26/00

CPCC23C24/08C09D5/103C23C26/00C09D5/10

Inventor 韩圭择

Owner 三株SMC株式会社

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com