Straight discharging grille cloth technique

A cloth and grille technology, applied in the field of vertical discharge grille cloth technology, can solve the problems of brick rotten edge, poor wear resistance, brick layering, etc., to prevent edge cracking, overcome late deformation, and prevent brick layering Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

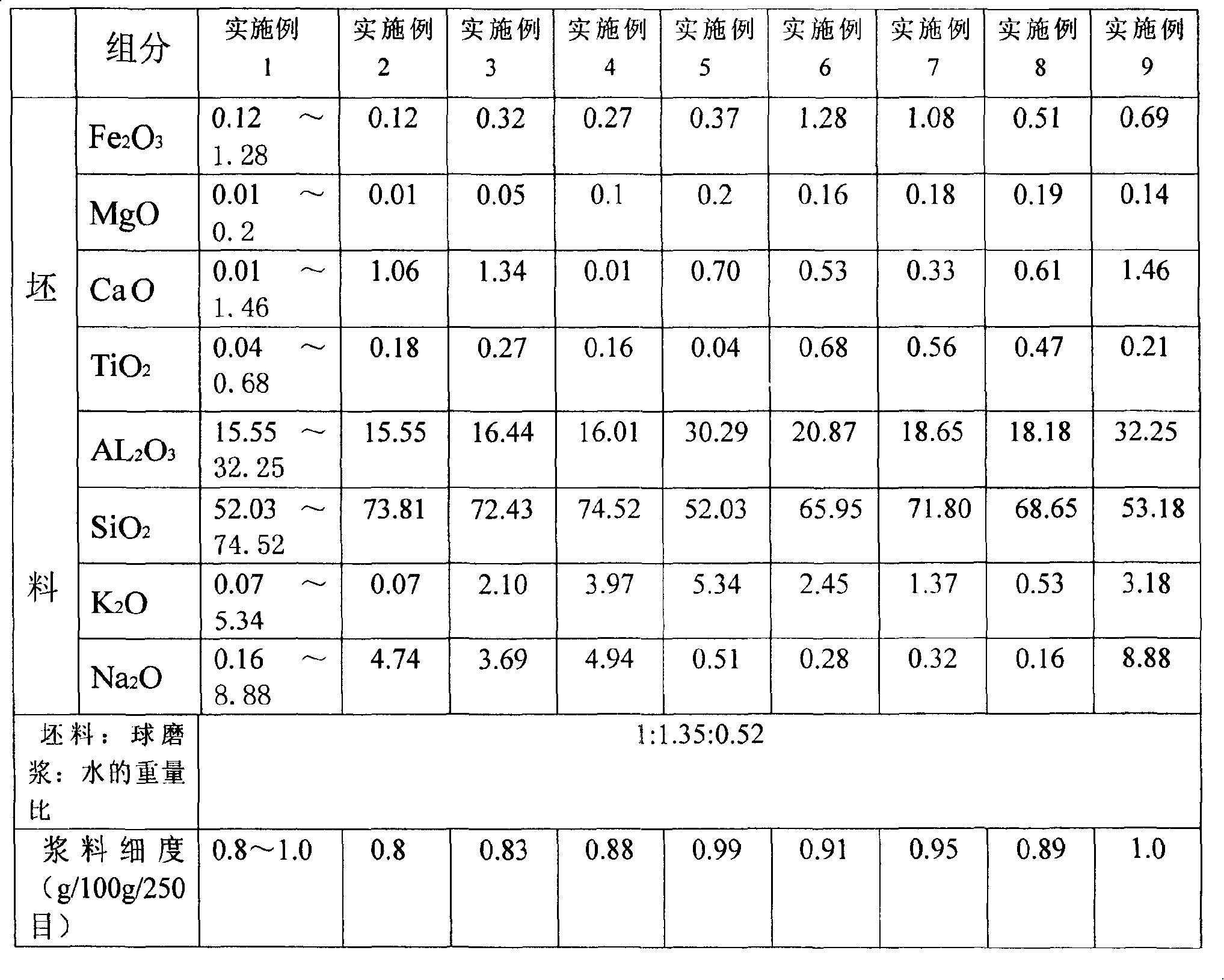

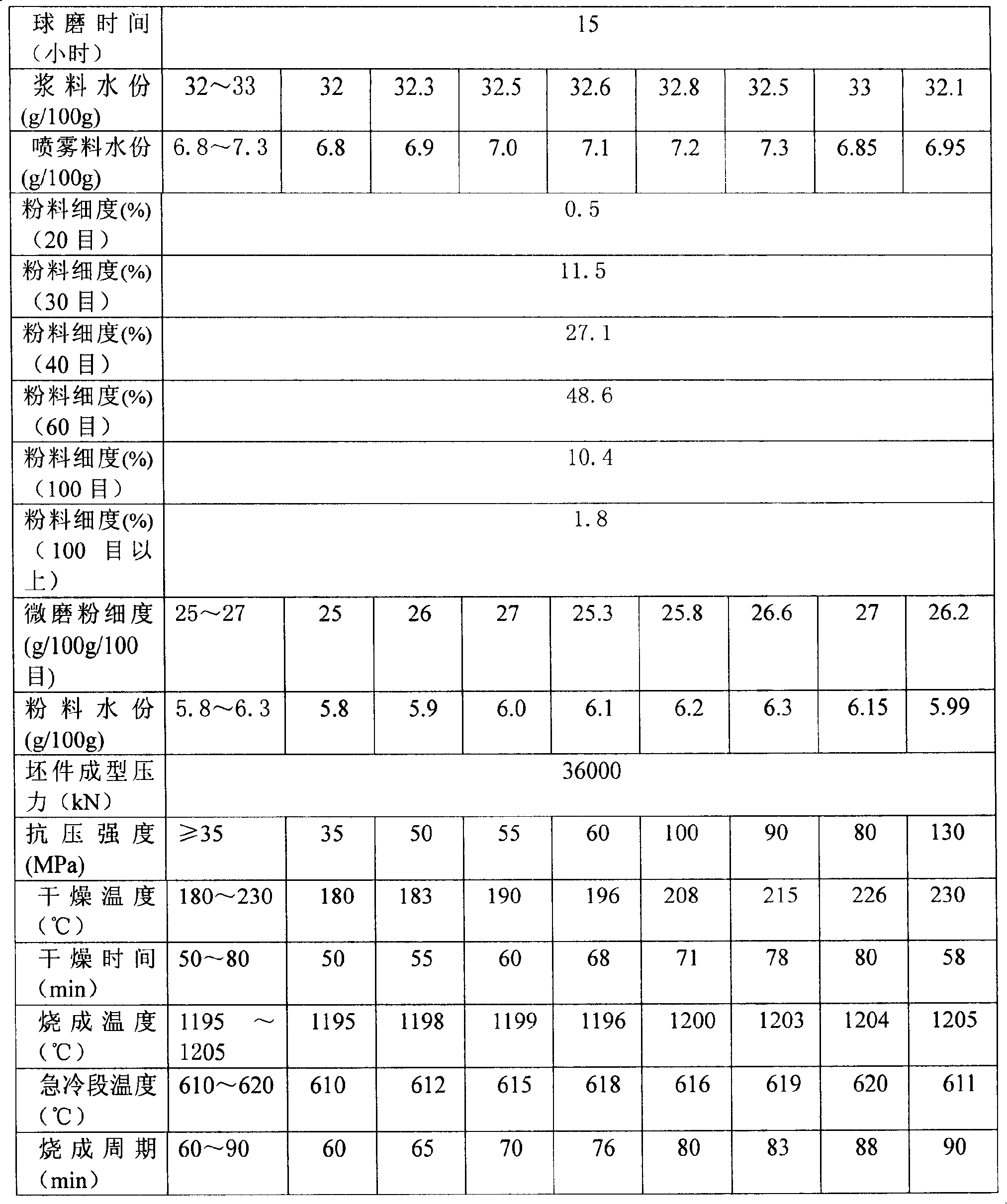

[0026] The present invention will be described in further detail below in conjunction with specific embodiment (billet unit is weight percent):

[0027] surface

[0028]

[0029] Continuation

[0030]

[0031] The ceramic tile manufacturing process is as follows: homogenization of raw materials → batching according to the above-mentioned embodiments into the mill → slurry → spray milling → computer cloth → press molding → seepage → drying → firing → polishing → inspection → packaging → storage .

[0032] The invention is produced by adopting two-way floating mold molding technology and straight discharge grid cloth technology. Compared with the existing one-way floating mold, the forming process of the two-way floating mold has great advantages: that is, the mold can be pressed and demolded in two directions during use, so as to form the forming effect of two-way pressure, so that the density of the adobe in the thickness direction It is more uniform, which can greatl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com