Method for producing ferulic acid esterase by solid fermentation

A technology of ferulic acid esterase and fermentation medium, which is applied in the field of fermentation industry, can solve the problems of high cost, low ferulic acid esterase activity, waste water pollution, etc., and achieve the goals of improving utilization rate, vigorous growth and reducing production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

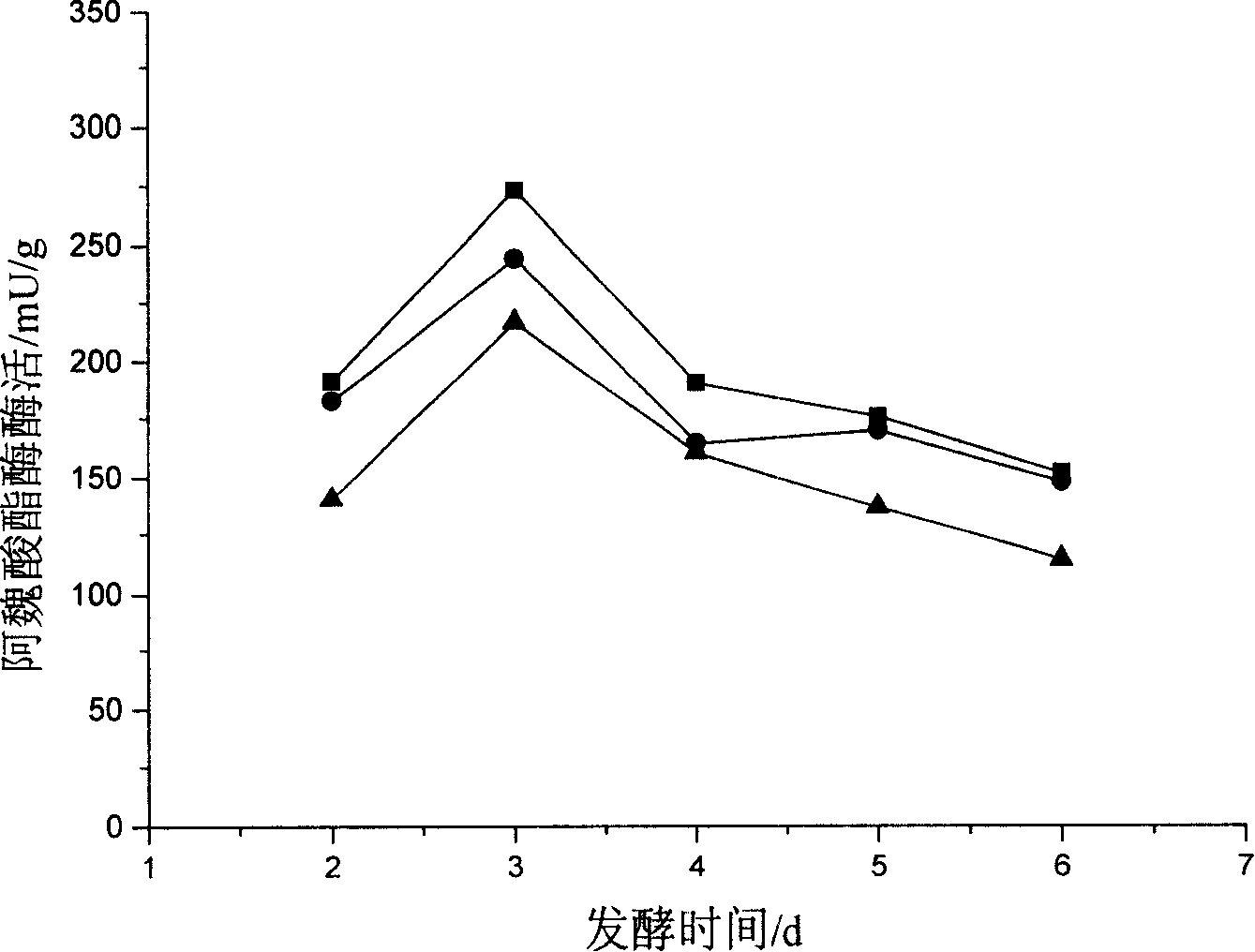

[0022] Embodiment 1: Production of ferulic acid esterase by steam-exploded wheat straw solid-state fermentation

[0023] 1. Steam-exploded wheat straw

[0024] Add 150g of wheat straw cut to a length of 10-15cm, add 150ml of water, stir evenly, put it into a steam explosion tank, and feed steam. After the cold air in the tank is discharged, close the charging valve, increase the pressure to 1.6MPa, and maintain the pressure for 4 minutes. Open the discharge valve and release the instant decompression to get the steam-exploded wheat straw.

[0025] 2. Preparation and sterilization of fermentation medium

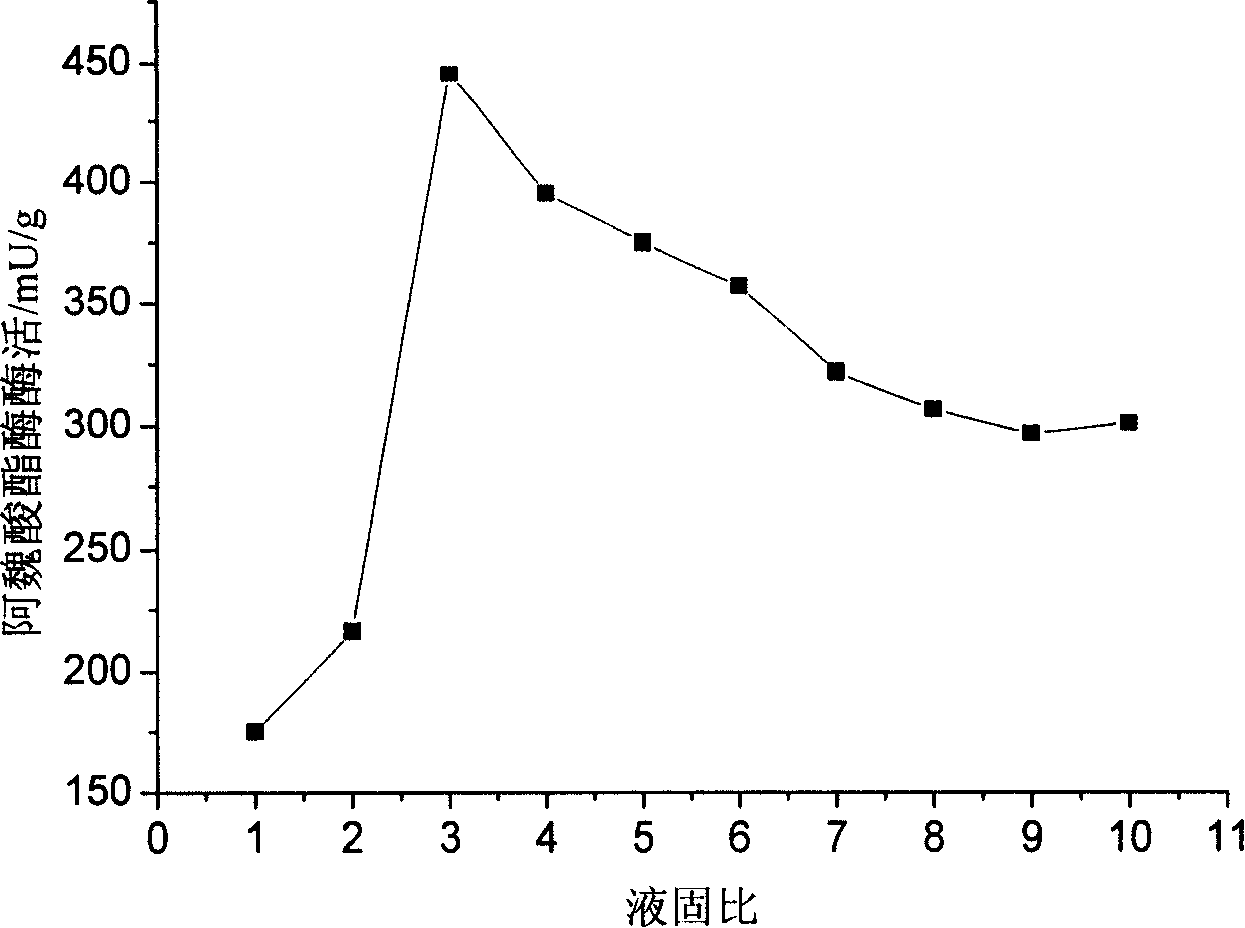

[0026] Add 1g of bran to 4g of steam-exploded wheat straw, add water to a solid-to-liquid ratio of 1:4, stir evenly, and keep the natural pH value in a sterilizing pot at 121°C for 30min.

[0027] 3. Vaccination

[0028] The sterilized culture medium was taken out, and 5 ml of Aspergillus niger liquid seeds obtained by screening were inserted into the ultra-clean bench, and...

Embodiment 2

[0032] Example 2: Ferulic esterase produced by steam-exploded rice straw solid-state fermentation

[0033] 1. Steam-exploded straw

[0034] Add 150g of straw cut to a length of 10-15cm, add 150ml of water, stir evenly, put it into a steam explosion tank, and feed steam. After the cold air in the tank is discharged, close the filling valve, increase the pressure to 1.6MPa, and maintain the pressure for 4 minutes. Open the discharge valve and release the instant decompression to get the steam-exploded straw.

[0035] 2. Preparation and sterilization of fermentation medium

[0036] Add 1g of bran to 4g of steam-exploded rice straw, add water to a solid-to-liquid ratio of 1:4, stir evenly, and maintain a natural pH value in a sterilizing pot at 121°C for 30min.

[0037] 3. Vaccination

[0038] The sterilized culture medium was taken out, and 5 ml of Aspergillus niger liquid seeds obtained by screening were inserted into the ultra-clean bench, stirred evenly, and cultured in a 3...

Embodiment 3

[0042] Example 3: Production of ferulic acid esterase by solid-state fermentation of steam-exploded corn stalks

[0043] 1. Steam-exploded corn stalks

[0044] Add 150g of corn stalks cut to a length of 3-5cm, add 150ml of water, mix evenly, put it into a steam explosion tank, and feed in steam. After the cold air in the tank is exhausted, close the charging valve and increase the pressure to 1.6MPa. After 4 minutes, open the discharge valve, and release the pressure instantly to get the steam-exploded corn stalks.

[0045] 2. Preparation and sterilization of fermentation medium

[0046] Add 1g of bran to 4g of steam-exploded corn stalks, add water to a solid-to-liquid ratio of 1:4, stir evenly, and maintain a natural pH value in a sterilizing pot at 121°C for 30min.

[0047] 3. Vaccination

[0048] The sterilized culture medium was taken out, and 5 ml of Aspergillus niger liquid seeds obtained by screening were inserted into the ultra-clean bench, stirred evenly, and cultu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com