Method for preparing Fe-Mn-Si magnetic shape memory alloy film

A memory alloy, fe-mn-si technology, applied in the preparation of magnetic shape memory alloy films, the field of preparation of Fe-Mn-Si magnetic shape memory alloy films, can solve the problem of magnetically induced strain stability and low repeatability, alloys The problems of high brittleness of bulk materials and high threshold of driving magnetic field can achieve the effect of low stress level, good thermal stability and excellent magnetic properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings, and embodiments of the present invention will be given.

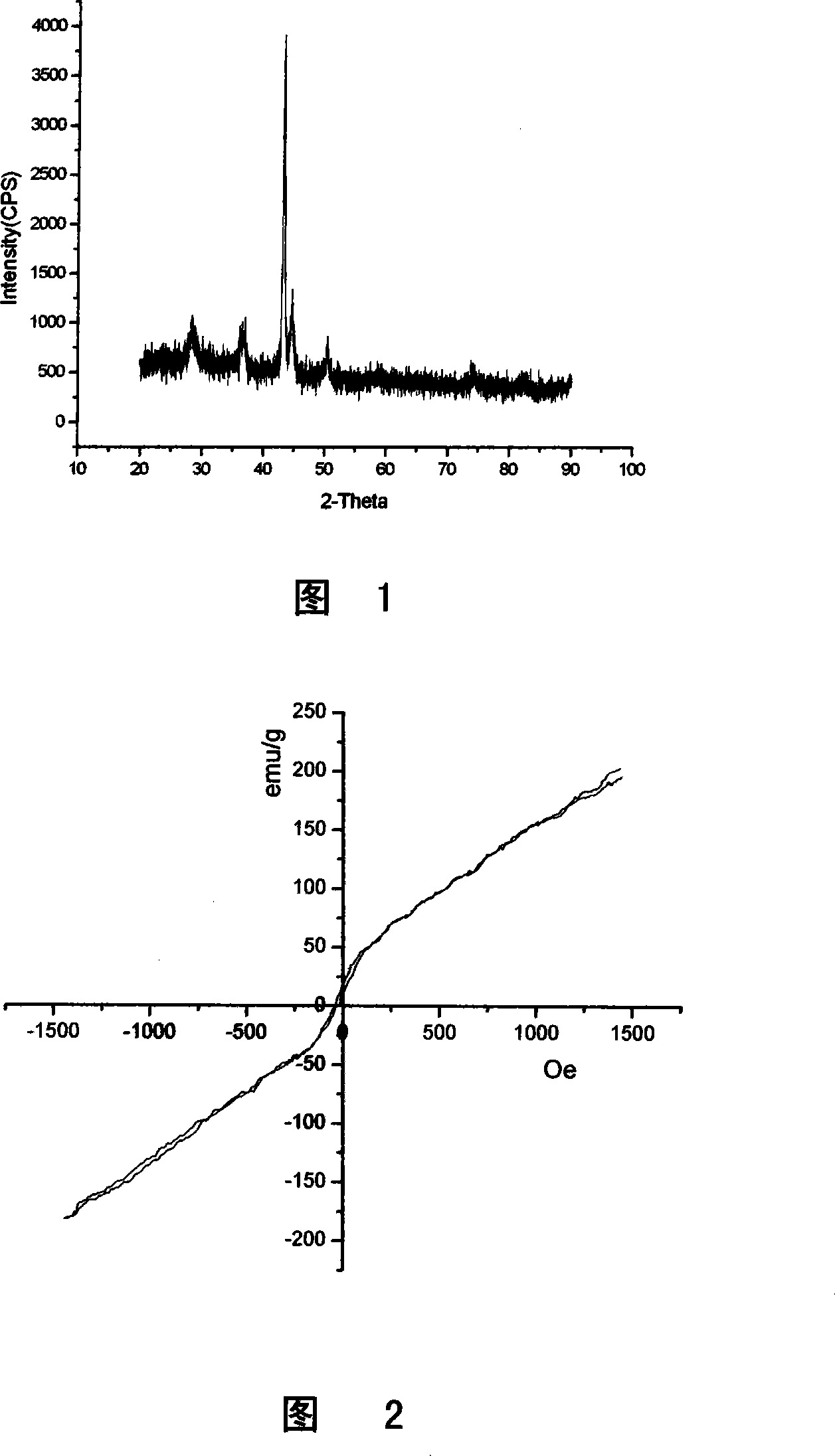

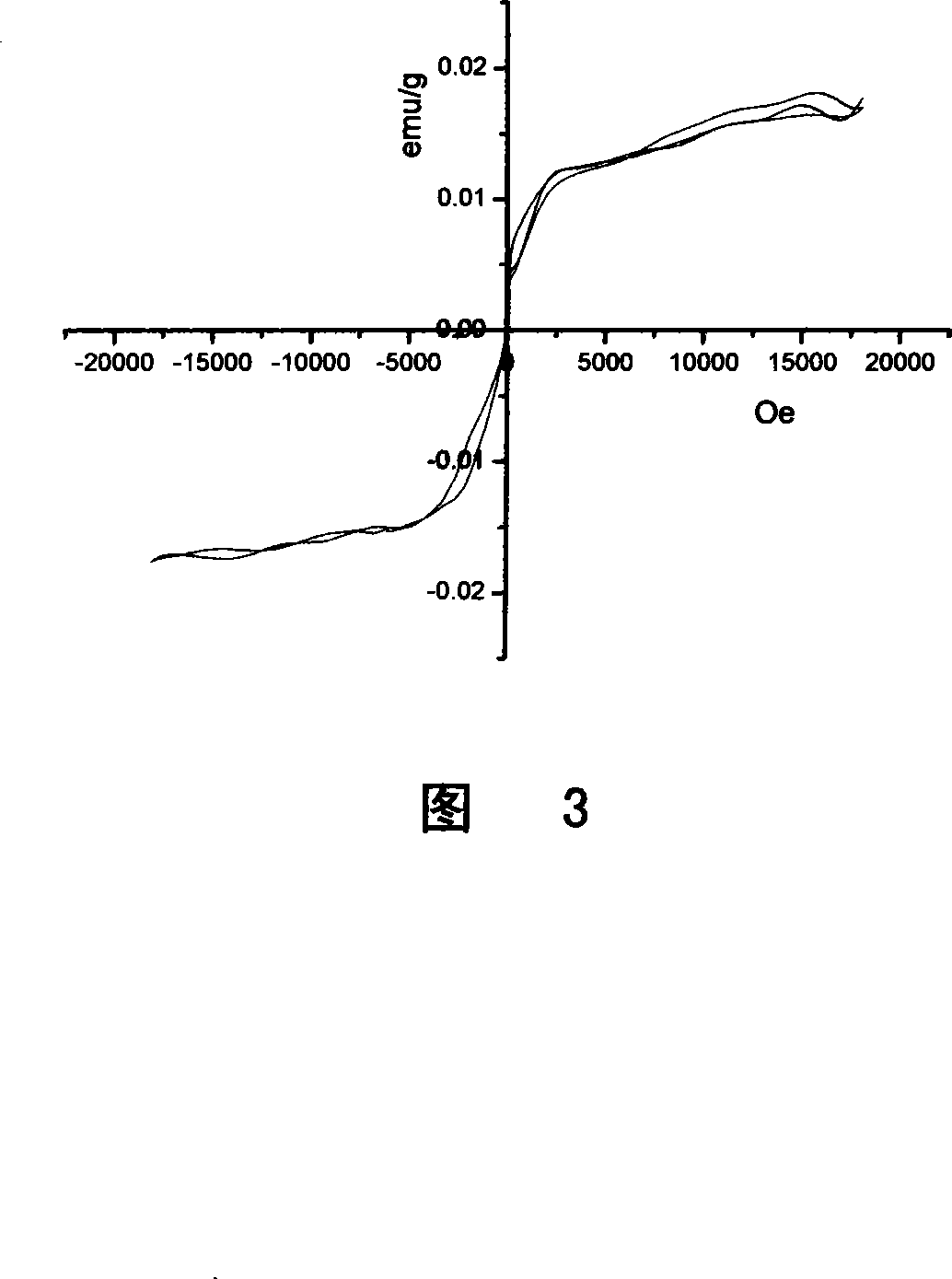

[0012] The method for preparing Fe-Mn-Si magnetic shape-memory alloy thin film, the main creative point of the invention lies in: preparing Fe-Mn-Si magnetic shape-memory alloy thin film by magnetron sputtering.

[0013] The specific process steps are: select an alloy whose alloy composition is Fe50Mn50-Fe70Mn30 to prepare an alloy target with a diameter of 50-60mm and a thickness of 1-5mm, and select a single crystal silicon with a diameter of 50-60mm and a thickness of 1mm as a single crystal Silicon target: use pure copper sheet or glass as the substrate, place the Fe-Mn alloy target and single crystal silicon target at a distance of 50cm from the base and at a position 60 degrees from the substrate. The vacuum degree of the sputtering backside is -5 Under the condition of Pa, the Ar pressure is kept at 0.1-1.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com