Preparation method for pumpkin juice

A technology of pumpkin juice and pumpkin, which is applied in the field of pumpkin juice preparation, can solve the problems of affecting the perception of parties, low work efficiency, overheating, etc., and achieve the effects of continuous production, improvement of labor efficiency, and reduction of labor burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

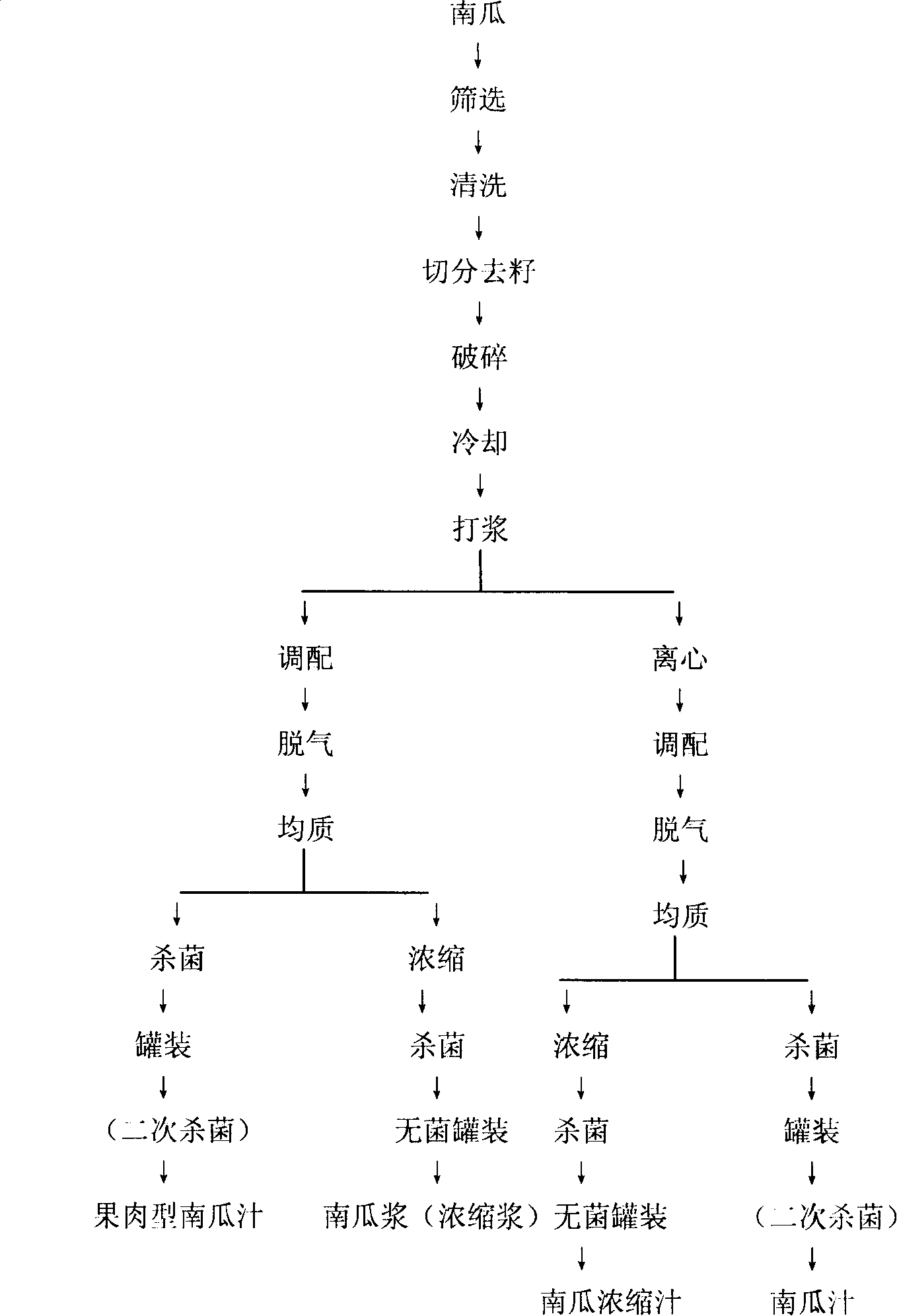

[0022] The preparation process of pumpkin juice: the pumpkin is screened by raw materials, cleaned, cut and seeded, replenished, crushed, pre-cooked, cooled, beaten, centrifuged, blended, degassed, homogenized, concentrated or non-concentrated, sterilized, filled and other processes And the processing technology of a kind of pumpkin juice (concentrated juice) that makes.

[0023] Select processed pumpkin varieties with carotenoids of more than 1mg / 100g, orange or orange red, high yield per mu and high juice yield as raw materials: after high-pressure spray cleaning, cut into 4-6 pieces according to the single weight of the pumpkin, remove Melon pedicle, melon pulp, melon seeds, etc.; crushed by a crusher into particles with a diameter of 1-5mm, adding rehydration at the same time, and the rehydration is calculated according to the weight ratio of each pumpkin. Water: sour agent: antioxidant = 1: 0.5 ~ 2: 0.0001~0.004: 0.00005~0.001, sour agents include one or more of citric ac...

Embodiment 1

[0025] Select processed pumpkin varieties with carotenoids of more than 1mg / 100g, orange or orange red, high yield per mu and high juice yield as raw materials: after high-pressure spray cleaning, cut into 4-6 pieces according to the single weight of the pumpkin, remove Melon pedicles, melon pulp, melon seeds, etc.; are broken into particles with a diameter of 1mm by a crusher, and rehydration is added at the same time, and the rehydration is calculated according to the weight ratio of each part of pumpkin. Then, through the closed continuous precooking equipment, the material is precooked to 90°C within 2 minutes, and the temperature is continuously supplied for 3 minutes until the material is cooked thoroughly but not rotten. The specific temperature and time depend on the selected pumpkin variety and its The amount of starch content is set; then the material is cooled to 70°C by closed continuous cooling equipment to ensure the homogeneous temperature requirements of the rea...

Embodiment 2

[0027] The difference from Example 1 is:

[0028] Break into particles with a diameter of 3mm by a crusher, and the rehydration is calculated according to the weight ratio of each part of pumpkin. Next, after the homogenization operation, the pumpkin juice is concentrated 4-5 times, so that its sugar content reaches 30-32°Bx, sterilized at 108°C for 30-40 seconds, and aseptically filled, which can be stored at room temperature. Pumpkin juice concentrate with no added preservatives.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com