Method for steady operation of low concentration firedamp gas switching catalytic reaction

A low-concentration gas, catalytic reaction technology, applied in the direction of combustion, combustion method, gas emission, etc. using catalytic materials, can solve problems such as instability, deactivation, destruction, etc., to improve safety, achieve elimination and utilization, methods Simple and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

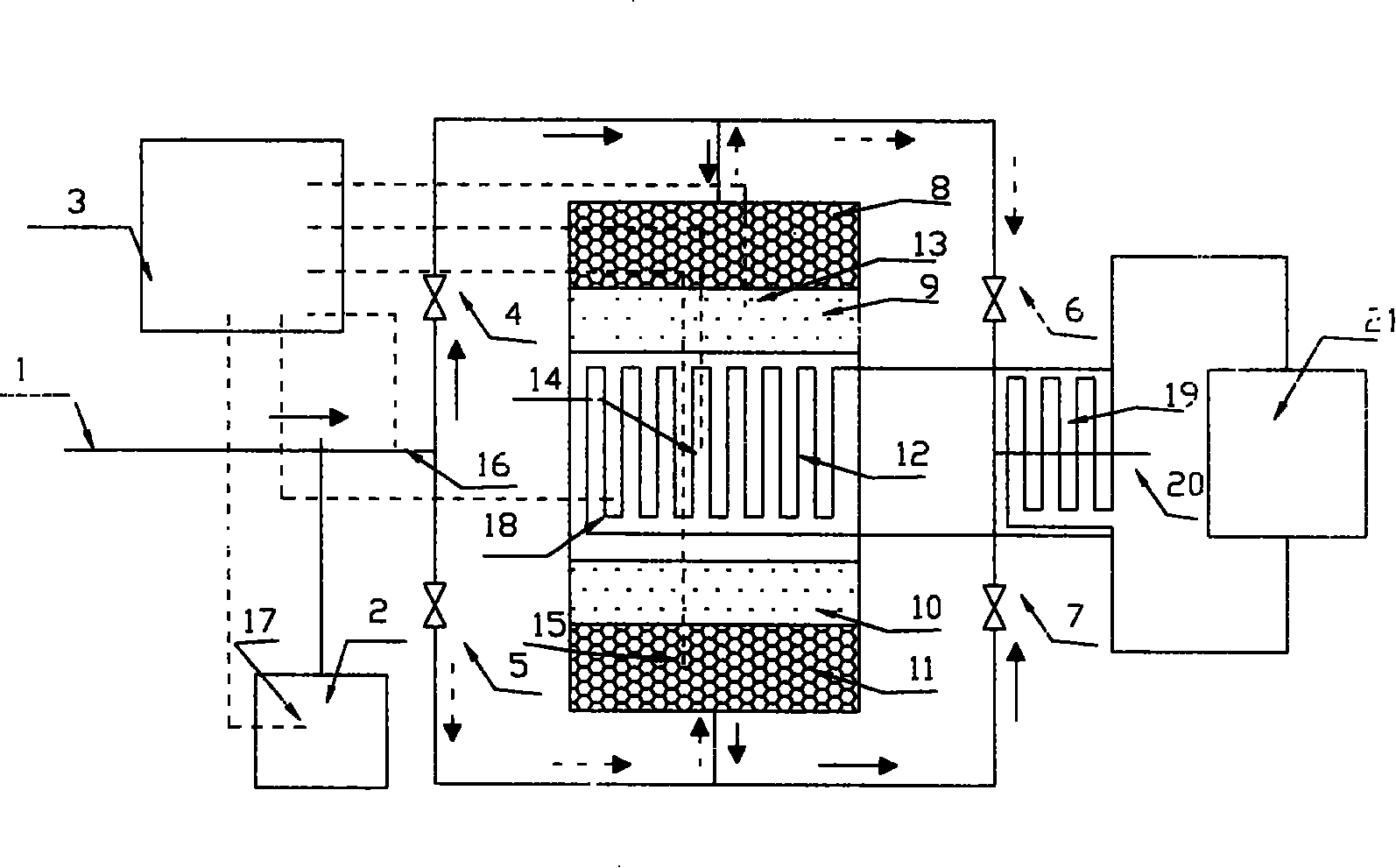

[0021] Such as figure 1 As shown, it is a schematic diagram of the structure and flow chart of the equipment used in the method for the stable operation of low-concentration gas switching catalytic reaction in the present invention, wherein, 1 is the low-concentration gas inlet, 2 is the valve for high-concentration coalbed methane, and 3 is signal acquisition and control system, 4, 5, 6, 7 are switching valves, 8, 11 are heat accumulators, 9, 10 are catalytic combustion reactors, 12 is high temperature heat exchangers, 13, 14, 15 are temperature signal acquisition units, 16 is Concentration signal acquisition unit, 17 is the valve control unit of high-concentration coalbed methane, 18 is the high-temperature heat exchanger control unit, 19 is the low-temperature heat exchanger, 20 is the flue gas outlet, and 21 is the heat energy utilization unit, which are connected as usual. The catalytic combustion reactors 9 and 10 use the catalyst provided in the patent of CN 1718274A. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com