Hollow titanium dioxide white electrophoresis ion for electrophoresis displaying and preparing method thereof

A titanium dioxide, electrophoretic display technology, applied in chemical instruments and methods, dyed polymer organic compound processing, optics, etc., to achieve the effects of easy availability of raw materials, uniform size, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0012] ① Disperse 0.10g of methyl methacrylate hollow polymer microspheres in 95mL of absolute ethanol, add 5.10g of titanate and 0.90g of deionized water, stir for 30min, and stand to obtain a white powder, which is a spherical hollow polymer / titanium dioxide Composite particles.

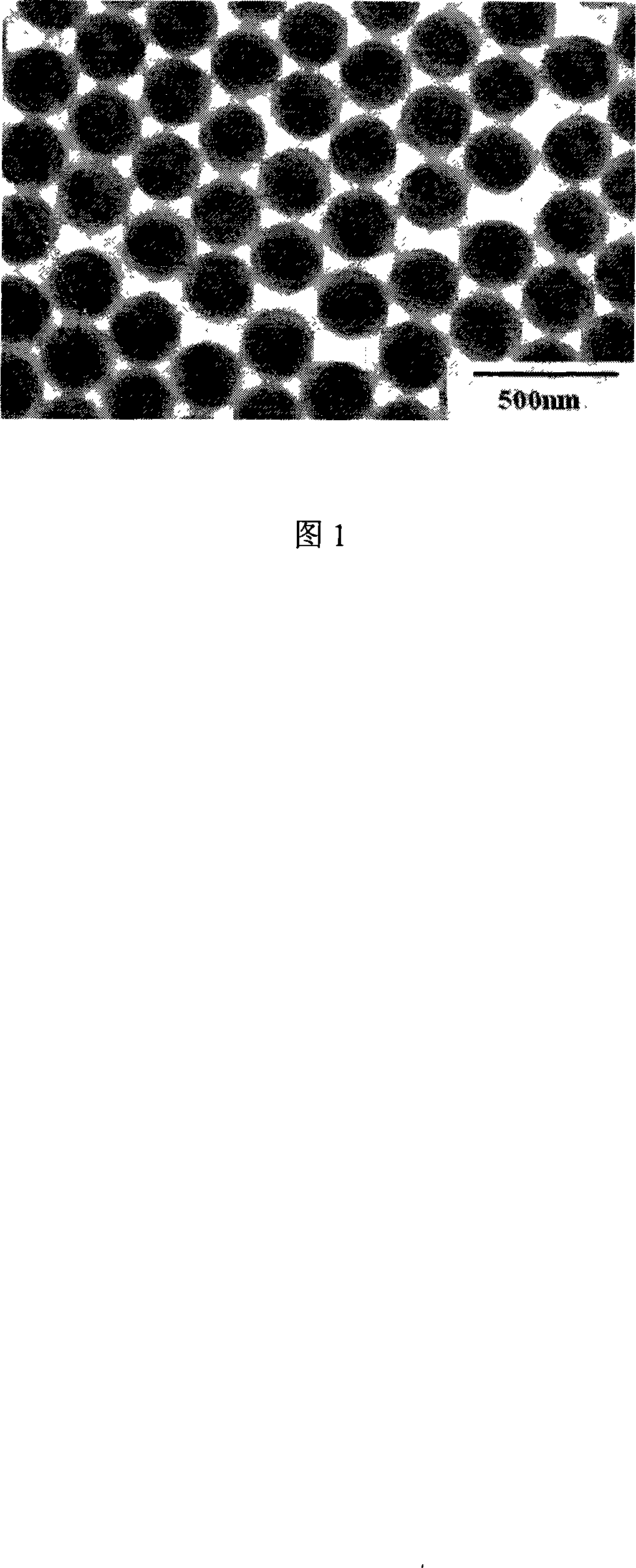

[0013] ②The hollow polymer / titanium dioxide composite particles were calcined at 1000°C for 5 hours in the air atmosphere to obtain white hollow titanium dioxide spherical particles with a uniform particle size of about 180nm and a relative density of 1.36g / cm 3 .

example 2

[0015] ① Take 0.25g of ethyl methacrylate polymer hollow microspheres and disperse them in 95mL of absolute ethanol, add 2.98g of titanate and 0.16g of deionized water, stir for 30min, and let stand to obtain a white powder, which is a spherical hollow polymer / Titanium dioxide composite particles.

[0016] ②The prepared white hollow polymer / titanium dioxide composite particles were calcined in air atmosphere at 900°C for 5 hours to obtain white hollow titanium dioxide spherical particles with a uniform particle size of about 320nm and a relative density of 2.04g / cm 3 .

example 3

[0018] ① Disperse 0.17 g of polystyrene hollow microspheres in 95 mL of absolute ethanol, add 4.30 g of titanate and 0.90 g of deionized water, stir for 30 min, and let stand to obtain a white powder, which is a spherical hollow polymer / titanium dioxide composite particle.

[0019] ③ The prepared white hollow polymer / titanium dioxide composite particles were calcined in air atmosphere at 900°C for 5 hours to obtain white hollow titanium dioxide spherical particles with a uniform particle size of about 180nm and a relative density of 1.84g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Relative density | aaaaa | aaaaa |

| Relative density | aaaaa | aaaaa |

| Relative density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com