Cleaning fermentation technique for neomycin

A fermentation process and neomycin technology, applied in the field of clean fermentation process of neomycin, can solve the problems of environmental pollution, waste of resources, and reduce the synthesis rate of products, so as to reduce the concentration of residual sugar, decrease the unit consumption of starch, and improve the sugar content. The effect of utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] Application of new technology in neomycin fermentation process in 60000L fermenter

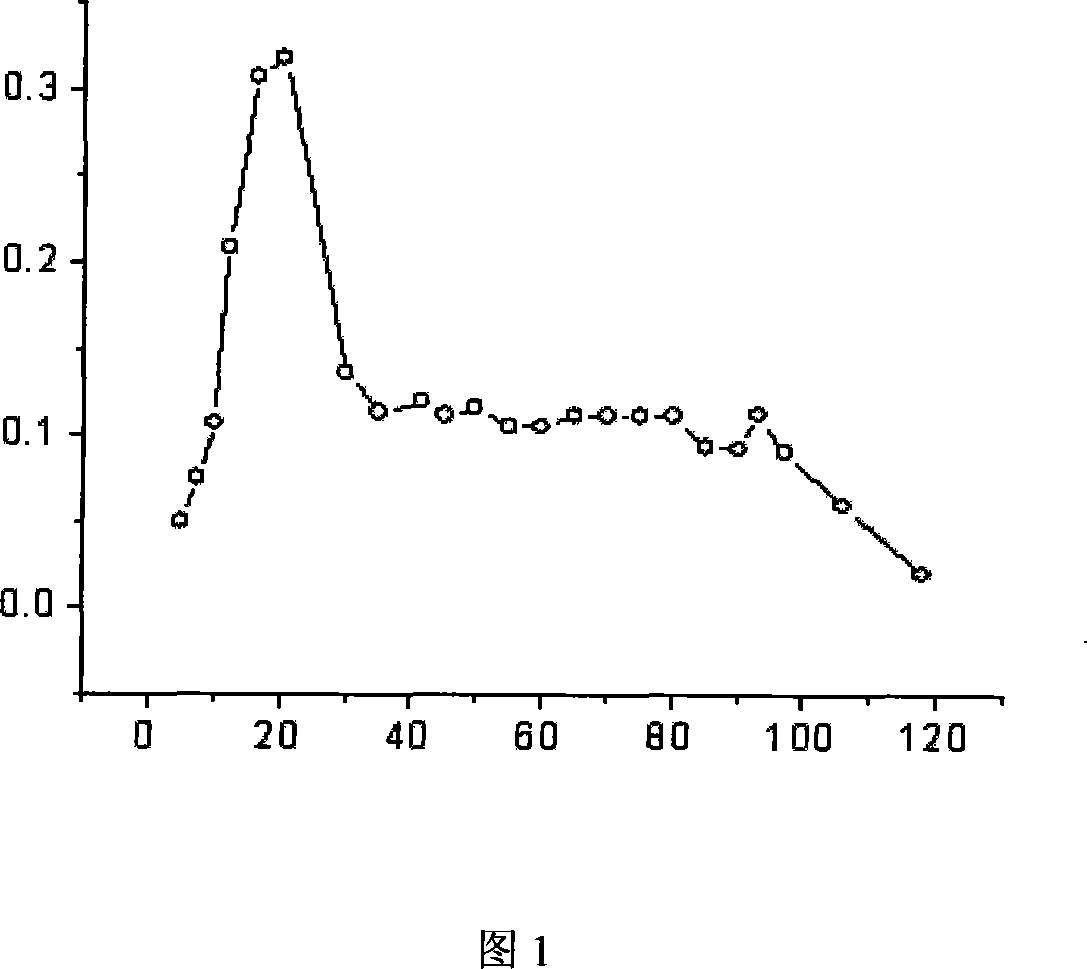

[0032] The temperature, pH, dissolved oxygen and other parameters of the fermentation process are monitored throughout the process. After 16 hours, samples were taken every 8 hours to measure the above parameters. Considering the loss of fermentation broth caused by evaporation, after 30 hours, continue to replenish water in the form of feeding, and the speed of replenishment shall be based on offsetting the evaporation volume. The whole fermentation cycle is about 120h. The new process improves the technical conditions such as the composition of the sugar supplement solution, the control of the feeding rate, and the pH program control. Established sugar supplement control, ammonium sulfate supplement control and pH control system. A more complete control mode has been determined.

[0033] Based on the neomycin fermentation in the 60000L fermenter, the parameters of the neomycin fer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com