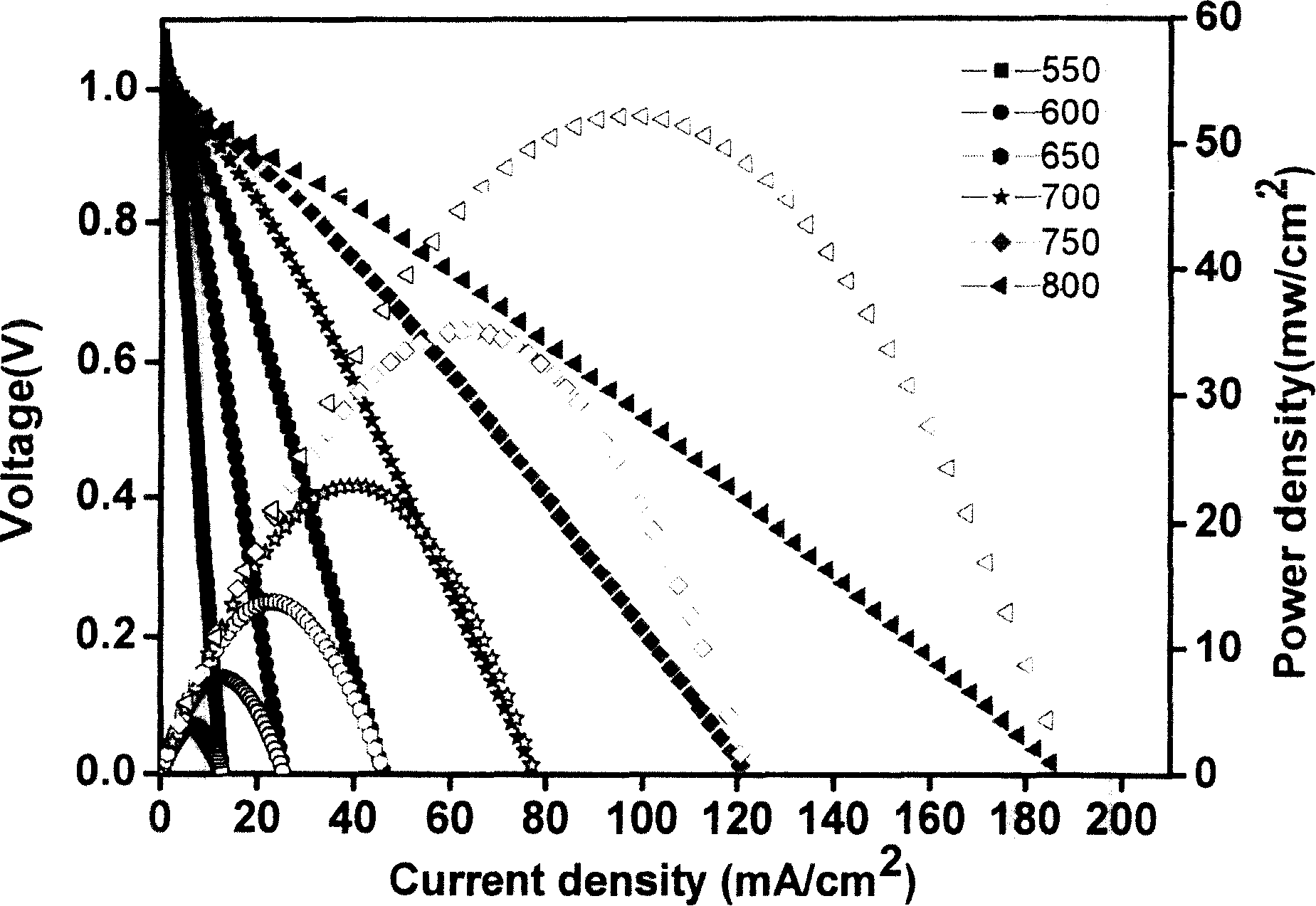

Ni-Ag nano material for anode of oxide fuel cell and method for synthesizing the material

A technology of fuel cells and nanomaterials, applied in fuel cell parts, battery electrodes, chemical instruments and methods, etc., can solve the problems of complex preparation methods, excessive interface resistance, low electrode catalytic activity, etc., and achieve simple preparation technology , equipment requirements are not high, the effect of large application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

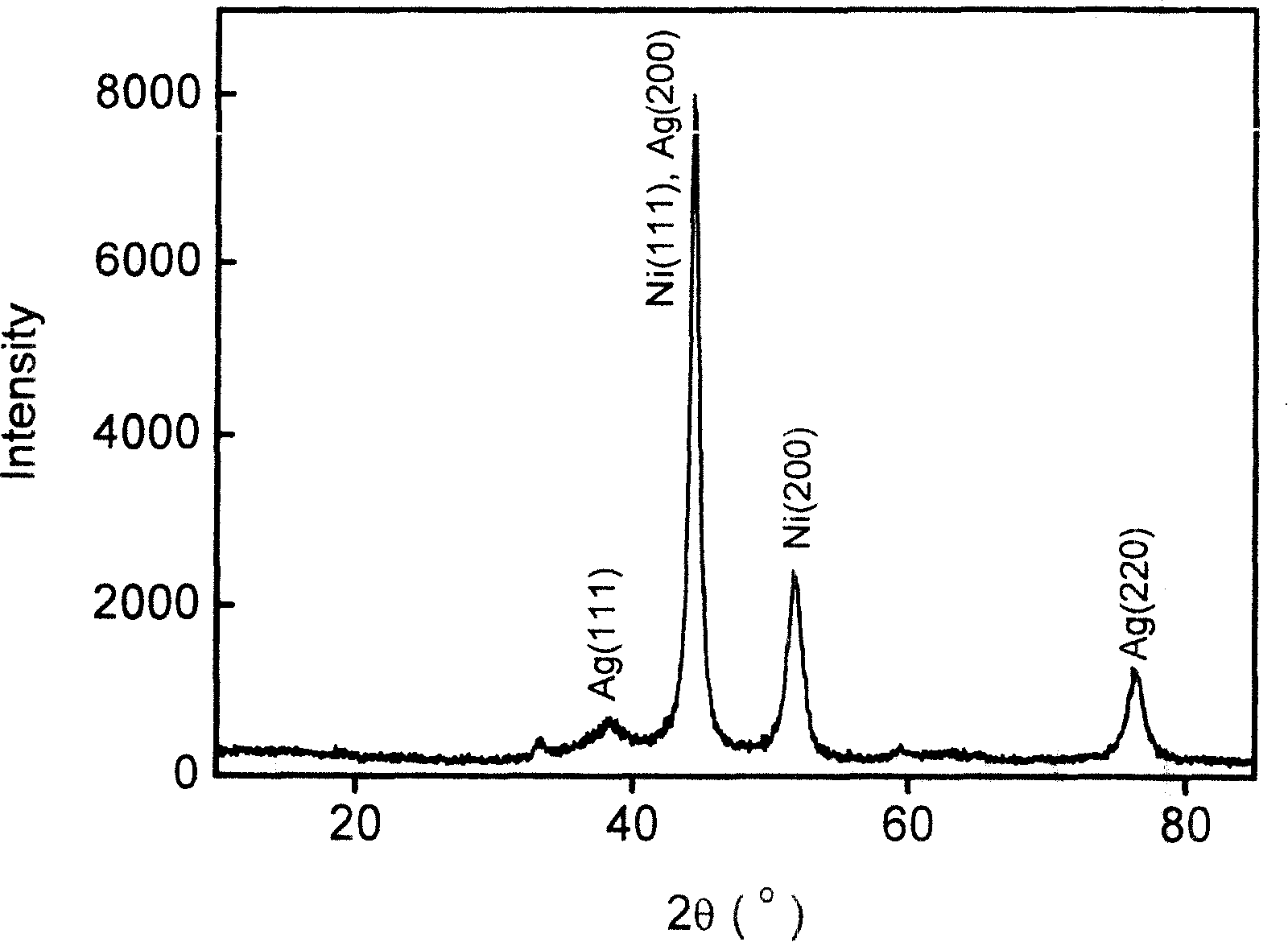

[0019] Example 1: Preparation of metal Ag1Ni99 nanopowder

[0020] Take AgNO 3 , Ni(NO 3 ) 2 · 2(H 2 O) The molar ratio is 1:99 dissolved in ethanol, the cation concentration is 0.1mol / L, and NaOH is - : M + =10:1 (M is the number of moles of cations, OH - is the number of moles of NaOH) was added to the above solution, the resulting mixture was fully stirred, and moved into a 30mL reactor (the filling degree was 70%), reacted in an oven at 180°C for 16h, cooled to room temperature after the reaction, suction filtered with distilled water, and dried The drying temperature is 60°C, and the black powdery nanometer metal is obtained.

example 2

[0021] Example 2: Preparation of metal Ag70Ni30 nanometer powder.

[0022] Take AgNO 3 , Ni(NO 3 ) 2 · 2(H 2 O) Dissolve in ethanol at a molar ratio of 7:3, the cation concentration is 0.1mol / L, and NaOH is - : M + =10:1 (M is the number of moles of cations, OH - is the number of moles of NaOH) added to the above solution, the resulting mixture was fully stirred, and moved into a 30mL reactor (filling degree: 70%), reacted in an oven at 180°C for 48h, cooled to room temperature after the reaction, filtered with distilled water, and dried The drying temperature is 60°C, and the black powdery nanometer metal is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com