Laminated Li-ion secondary battery and method for producing the battery

A secondary battery and lithium ion technology, which is applied in secondary battery, electrolyte battery manufacturing, electrode manufacturing, etc., can solve the problems of low weight specific capacity, good cycle performance, high short circuit rate, etc., to improve cycle performance and increase battery capacity , Increase the effect of electrode weight specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] The preparation method of the battery provided by the present invention includes the positive electrode current collector supporting the positive electrode material to obtain the positive electrode, the negative electrode current collector supporting the negative electrode material to obtain the negative electrode, a separator is arranged between the positive electrode and the negative electrode to form an electrode group, and the electrode group is contained in the battery The electrolyte is injected into the casing, and then the battery casing is hermetically sealed, wherein the positive electrode current collector and / or the negative electrode current collector are foamed metal, the thickness of the foamed metal is 0.5-3 mm, and the tensile strength is not less than 120 Newton / cm², porosity is not less than 80%. Preferably, the foam metal has a thickness of 1-2.5 mm, a tensile strength of 120-200 Newton / cm², and a porosity of 90-95%.

[0015] The method of loading the po...

Embodiment 1

[0029] This embodiment illustrates the positive electrode provided by the present invention, a preparation method thereof, and a lithium ion secondary battery including the positive electrode.

[0030] (1) Preparation of positive electrode

[0031] Dissolve 110 grams of polyvinylidene fluoride (PVDF) in about 1500 grams of N-methylpyrrolidone (NMP) solvent to prepare a binder solution, and then mix 3200 grams of lithium cobalt oxide (UM’s KD10 lithium cobalt oxide) with 30 Grams of acetylene black powder acting as a conductive agent was added to the above solution, fully stirred and mixed uniformly to prepare a positive electrode slurry; the positive electrode slurry was evenly coated with a stretcher to a thickness of 1.5 mm and a tensile strength of 125 Newtons / Square centimeters, the porosity of the aluminum foam is 92% on both sides, and the weight ratio of the positive electrode slurry to the positive electrode current collector is 15:1. After heating and drying in vacuum at...

Embodiment 2-5

[0041] The embodiments illustrate the positive electrode provided by the present invention, a preparation method thereof, and a lithium ion secondary battery including the positive electrode.

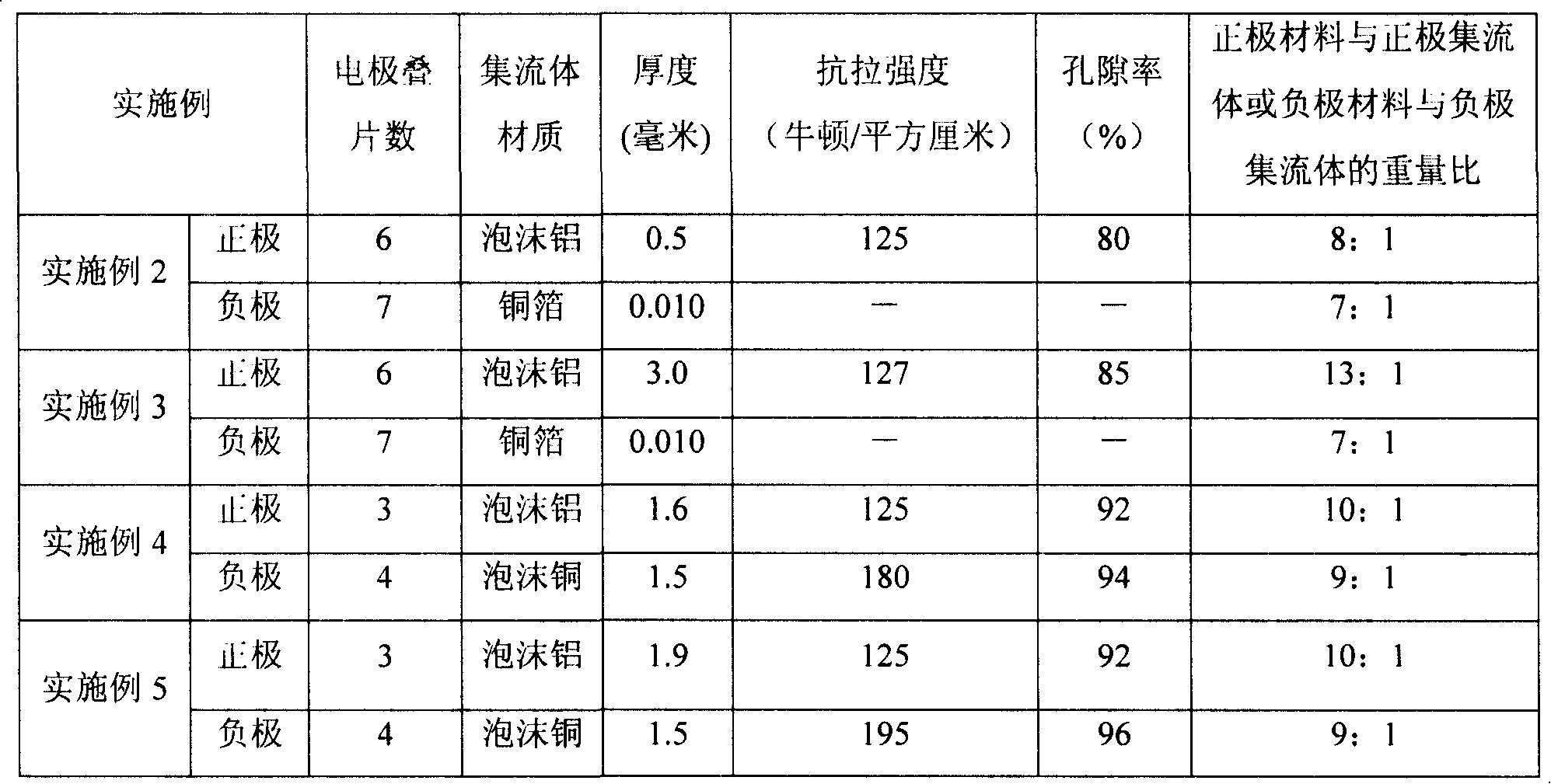

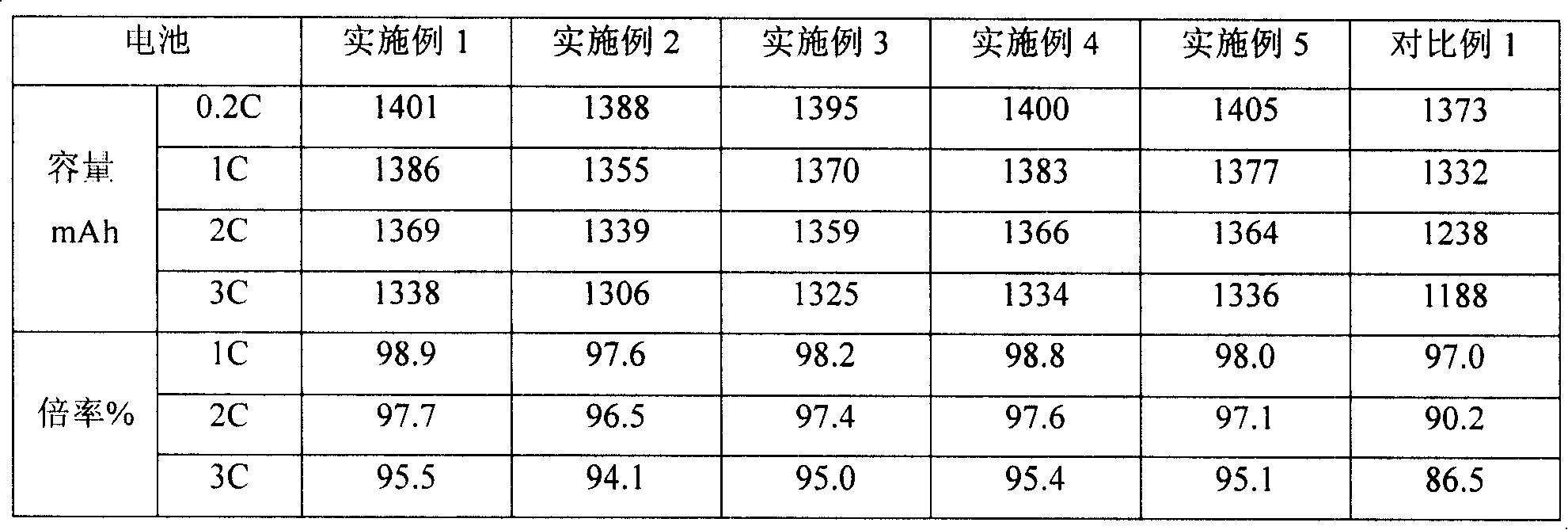

[0042] A positive electrode and a battery including the positive electrode were prepared according to the method of Example 1. The difference is that the material, thickness, tensile strength, porosity, and weight ratio of the electrode material of the electrode to the current collector are as shown in Table 1 below. Show.

[0043] Table 1

[0044]

[0045] Among them, the preparation method of the negative electrode of Example 4-5 is 960 grams of conductive graphite (soddif product, DAG22) powder, fully mixed with 40 grams of polyvinylidene fluoride (PVDF) as a binder, and dissolved to about 500 grams as a solvent. In the N-methylpyrrolidone, stir and mix well to obtain a negative electrode slurry. Use a stretcher to evenly coat the negative electrode slurry with a thickness of 1.5 mm, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com