Aldol condensation catalyst and use thereof

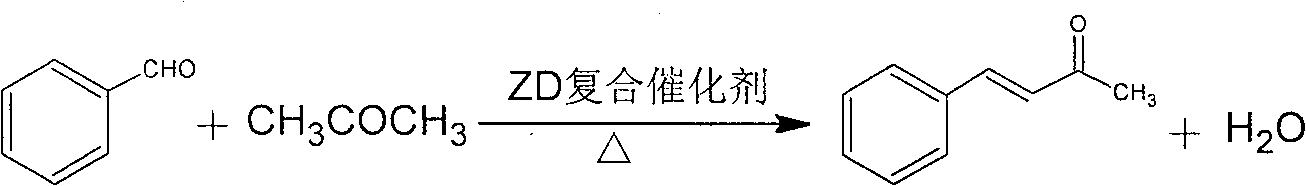

A technology of aldol condensation and catalyst, which is applied in the field of aldol condensation catalyst and in the synthesis of 4-phenyl-3-buten-2-one, and can solve the problem of high price of phase transfer catalyst, troublesome post-processing, and difficult issues of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

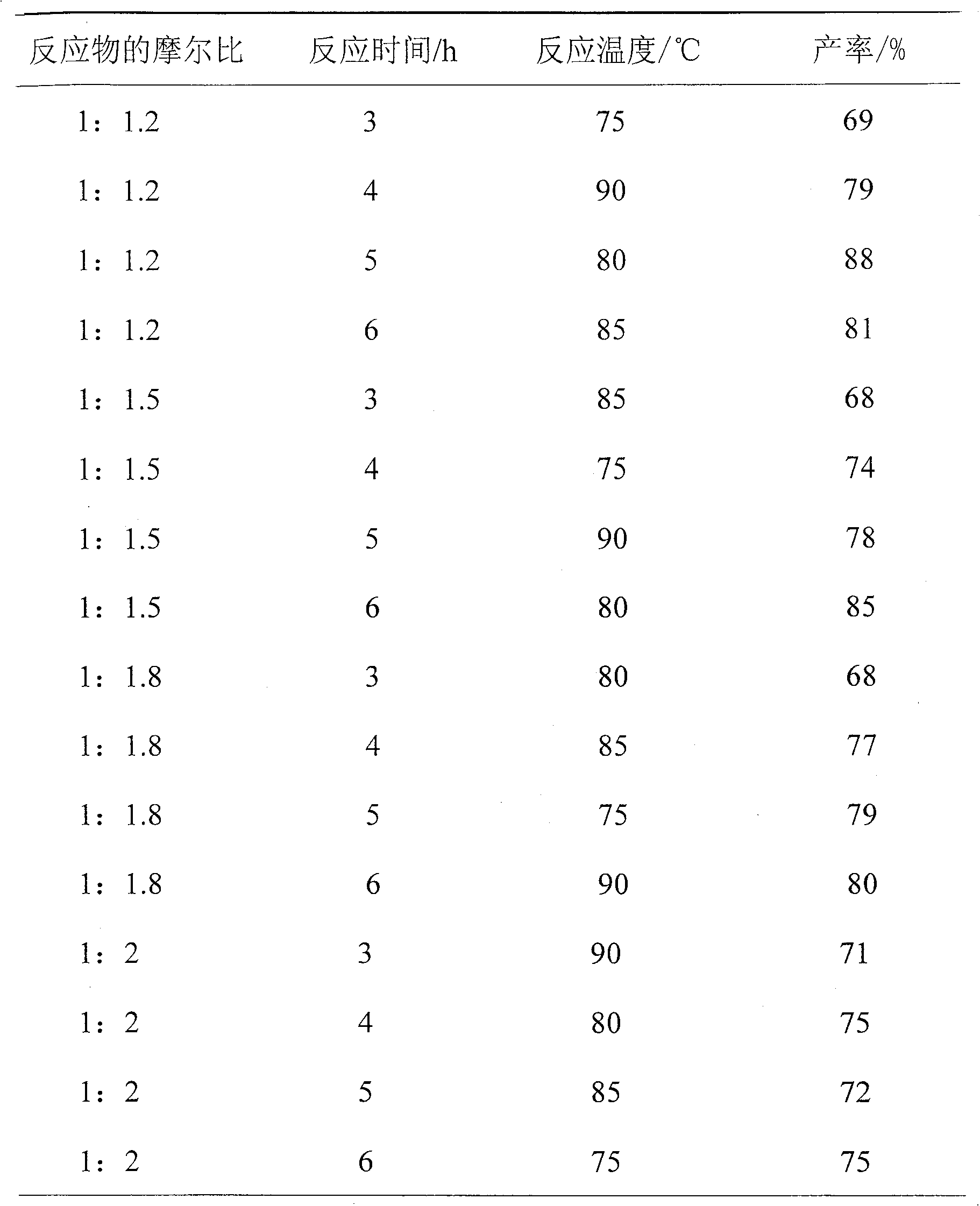

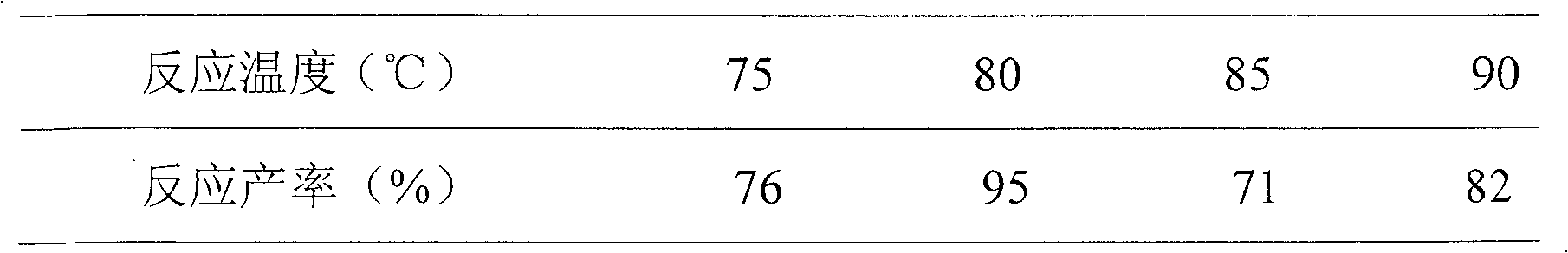

Method used

Image

Examples

Embodiment 1

[0007] Select Al with a diameter of 0.6mm 2 o 3 Particles as carrier, with powdered 5% CaO, 4% MgO, 1% La 2 o 3 , 0.01% Pt, 0.02% Pd, the balance is Al 2 o 3 , after stirring evenly, add 5% sodium carboxymethylcellulose solution as a binder, stir to form uniform particles, dry, activate at 200°C for 2 hours, cool down to room temperature naturally, and put it in a desiccator for later use . The usual dosage is 0.5%. Abbreviation: ZD composite catalyst.

Embodiment 2

[0009] Select Al with a diameter of 0.8mm 2 o 3 Particles as carrier, with powdered 10% CaO, 3% MgO, 1.5% La 2 o 3 , 0.015% Pt, 0.01% Pd, the balance is Al 2 o 3 After stirring evenly, add an appropriate amount of sodium carboxymethylcellulose solution as a binder, stir to form uniform particles, dry, activate at 300°C for 1.5 hours, cool down to room temperature naturally, and put it in a desiccator for later use. The usual dosage is 0.5%. Abbreviation: ZD composite catalyst.

Embodiment 3

[0011] Choose Al with a diameter of 1mm 2 o 3 Particles as carrier, with powdered 15% CaO, 5% MgO, 2% La 2 o 3 , 0.02% Pt, 0.015% Pd, the balance is Al 2 o 3 After stirring evenly, add an appropriate amount of sodium carboxymethylcellulose solution as a binder, stir to form uniform particles, dry, activate at 200-300°C for 2 hours, cool down to room temperature naturally, and put it in a desiccator spare. The usual dosage is 0.5%. Abbreviation: ZD composite catalyst.

[0012] Utilize the catalyst of above-mentioned preparation to produce 4-phenyl-3-buten-2-one:

[0013] Add 100ml of benzaldehyde, 90ml of acetone and 1g of ZD composite catalyst in sequence in a 50ml round bottom flask equipped with a reflux tube, heat in a water bath at 80°C, stir for 6h with a magnetic force, and then filter to obtain a light yellow liquid, which is evaporated under reduced pressure for production.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com