Method of preparing diamond bead

A diamond beading and manufacturing method technology, which is applied in the field of wire saw manufacturing, can solve the problems of short service life, low production efficiency, and easy damage, and achieve the effects of good bonding reliability, extended service life, and simple assembly and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

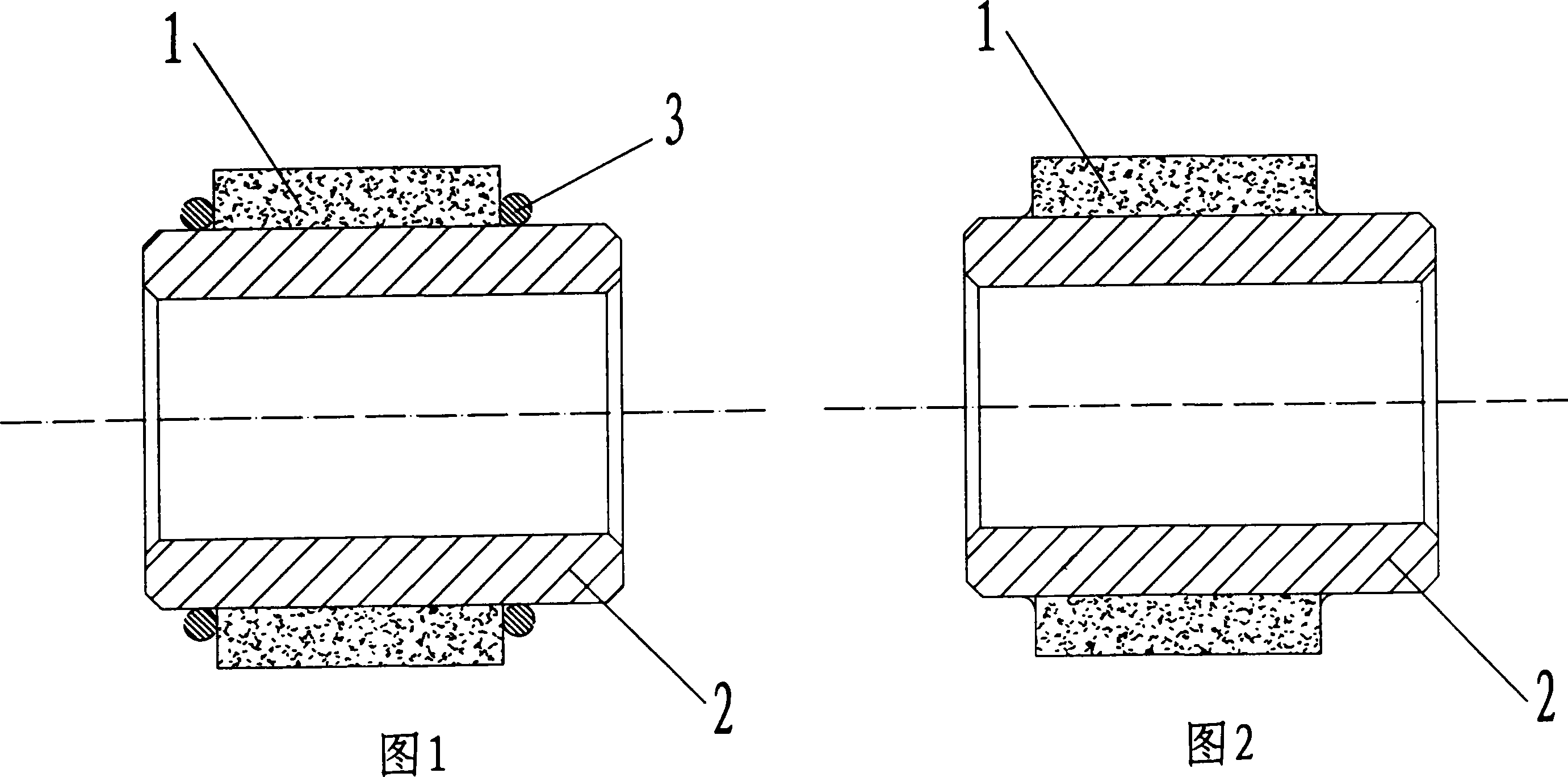

Image

Examples

Embodiment 1

[0026] 1 kg of Co, Sn, and Ni metal powders in a ratio of 80%: 5%: 15%;

[0027] Put the proportioning material into the GM130 three-dimensional mixer and dry mix for 90 minutes;

[0028] Add 42 grams of 40 / 50 particle size diamond and 100 ml of isopropanol with a concentration of 60% to mix with 100 ml of binder and wet mix for 60 minutes to make it uniform;

[0029] Put the mixed wet material into GA180 granulator for granulation;

[0030] Make bead body 1 by cold pressing forming, in the present embodiment, the external diameter of bead body 1 is 11 millimeters, and internal diameter is 8.5 millimeters, and blank length is 7.5 millimeters, and the selected steel mold has the quantity of molding die holes on it as 6 . Use a balance to divide the pellets into 6 parts (2.1 grams each), fill them into the 6 forming die holes one by one, vibrate the steel mold to make the pellets in each hole dense and even, and select a punching machine with six heads that matches the steel m...

Embodiment 2

[0037] With C0, Sn, Fe, Ni metal powder by 45%: 5%: 35%: 15% proportioning 1 kilogram;

[0038] Put the proportioning material into the GM130 three-dimensional mixer and dry mix for 90 minutes;

[0039] Add 36 grams of 40 / 50 grain size diamond and 100 ml of isopropanol with a concentration of 60% of the binder and wet mix for 60 minutes to make it uniform;

[0040] Put the mixed wet material into GA180 granulator for granulation;

[0041] The bead body 1 is made by the cold pressing molding process. In the present embodiment, the outer diameter of the bead body 1 is 11.5 millimeters, the inner diameter is 7.8 millimeters, and the blank length is 7.0 millimeters. Use a balance to divide the granules into 8 parts (2.8 grams per part), fill them one by one into the 8 forming die holes, vibrate the mold to make the granules in each hole dense and even, and select a steel mold with 8 heads that matches the steel mold. The stamping head is formed and stamped on a 100T hydraulic pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Body length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com