Method of preparing full bamboo or bamboo wood composite oriented structure shaving board

A bamboo-wood composite and manufacturing method technology, applied in the direction of manufacturing tools, flat products, wood processing appliances, etc., can solve the problems of complex production process, high manufacturing cost, and wood oriented particle board does not meet the economic cost, etc., and achieves the convenience of raw materials , Low manufacturing cost, high-quality and low-cost products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

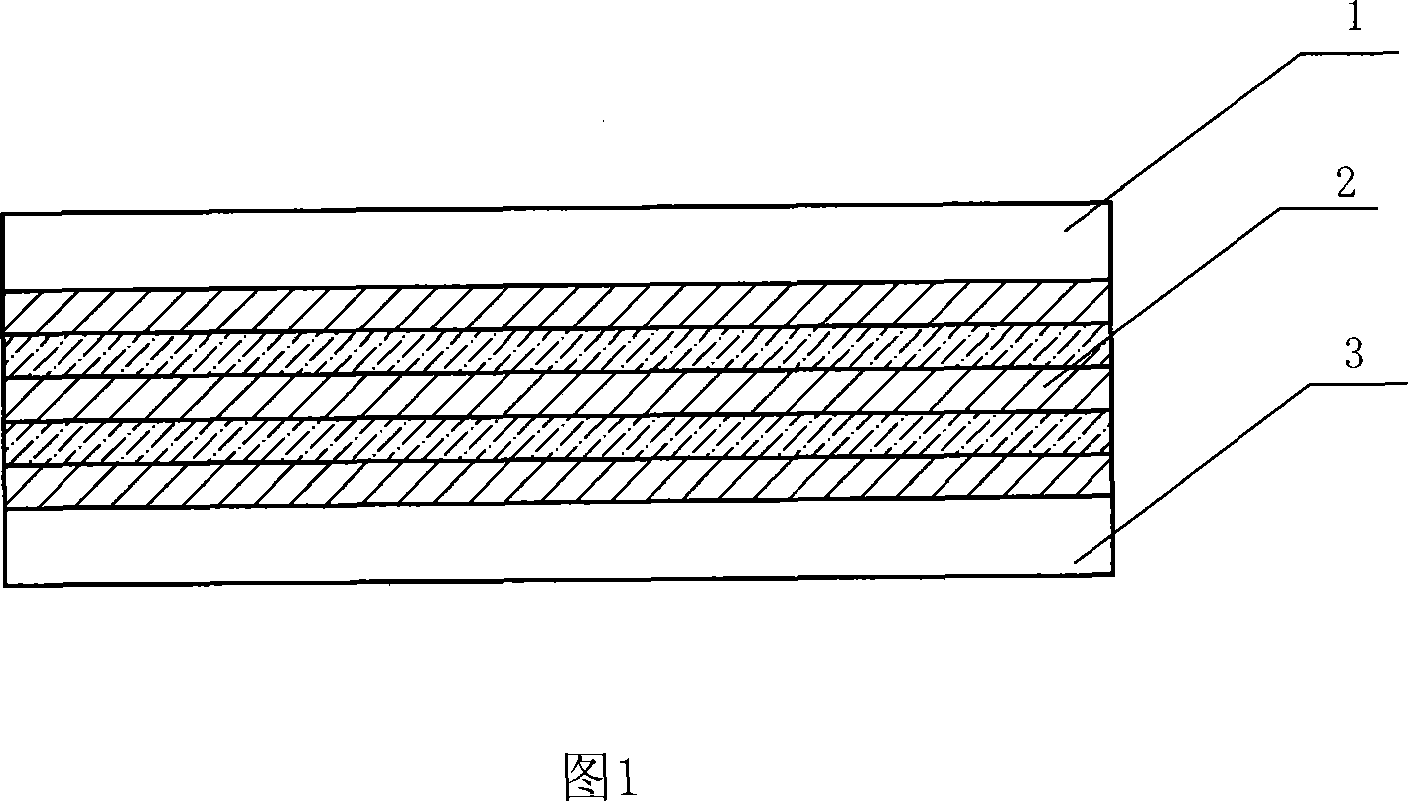

[0022] The present invention will be further described below in conjunction with accompanying drawing:

[0023] To make bamboo-wood oriented particle board, choose bamboo with a diameter greater than 50mm and fast-growing wood to make bamboo and wood-mixed oriented particle board, and complete it according to the following process:

[0024] (1) at first the bamboo tube section that bamboo is cut into 90mm long, will be peeled by wood;

[0025] (2) the bamboo tube section that contains green bamboo, bamboo reed and the log that peels are cut through the flaker or sliced along the length and be 90mm, be thick to be 0.8mm, the wood chip of width 25mm and take the wall thickness of bamboo as Bamboo slices of width;

[0026] (3) Bamboo chips and wood chips after cutting or slicing are dried to a moisture content of 8% through a drier;

[0027] (4) enter the gluing machine after mixing the dried bamboo chips and wood chips for sizing;

[0028] (5) Bamboo, logs, and the fragment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com