Technique and deice for preparing high purity boron trifluoride gas

A boron trifluoride and gas technology, which is applied in the field of preparing high-purity boron trifluoride gas, can solve the problems of high impurity content of boron trifluoride gas, large amount of sulfuric acid, equipment corrosion, etc., and achieve safe operation of equipment and simple equipment , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

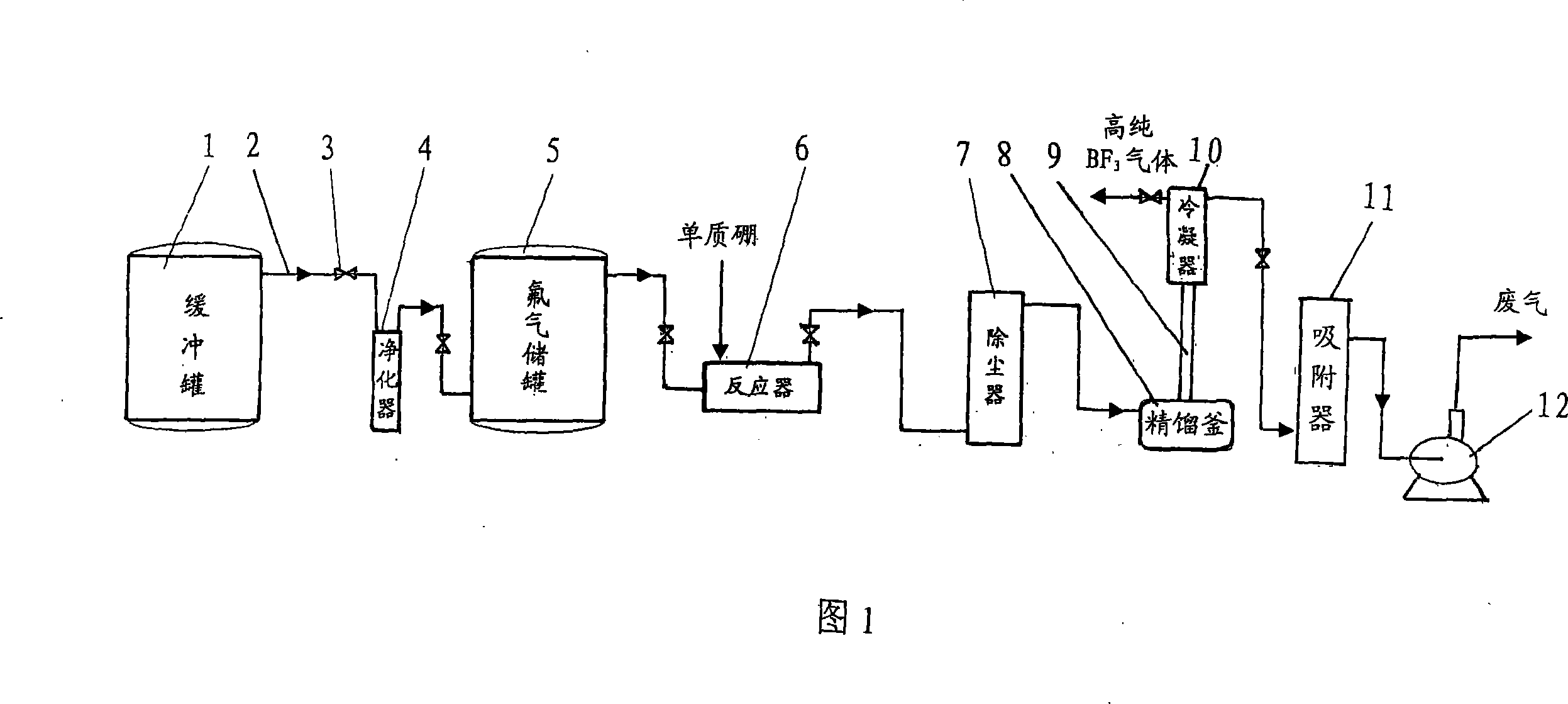

[0031] First, 2 kg of elemental boron with a purity of 92% is added into the reactor, and the reactor is preheated to 150° C. Use liquid nitrogen to freeze the purifier 4 to -185°C, open the valve 3, the fluorine gas in the buffer tank 1 enters the purifier 4 for liquefaction and collection, after the purifier 4 is collected, close the valve 3 to remove most of the hydrogen, oxygen and nitrogen Waiting for high boiling point substances, heat up the purifier 4, gradually thawed fluorine gas enters the fluorine gas storage tank 5 through the pipeline, and the purifier 4 heats up to -140 ° C, and stops heating up. At this time, the pressure of the fluorine gas storage tank 5 is 0.18Mpa. Open the reactor inlet valve and the fluorine gas enters the reactor 6 through the pipeline to carry out the synthesis reaction with elemental boron, and the reaction product is boron trifluoride gas (BF 3 ).

[0032] Analyzing the composition of the gas at the outlet of the reactor, the gas con...

Embodiment 2

[0038]2 kg of elemental boron with a purity of 92% was added into the reactor, and the reactor was preheated to 240° C. Use liquid nitrogen to freeze the purifier 4 to -195°C, open the valve 3, the fluorine gas in the buffer tank 1 enters the purifier 4 for liquefaction and collection, after the purifier 4 is collected, close the valve 3 to remove most of the hydrogen, oxygen and nitrogen Waiting for high boiling point substances, heat up purifier 4, gradually thawed fluorine gas enters fluorine gas storage tank 5 through pipeline, purifier 4 heats up to -145 ℃, stops heating up. At this moment, the pressure of the fluorine gas storage tank 5 is 0.15Mpa. Open the reactor inlet valve 3 and fluorine gas enters the reactor 6 through the pipeline to carry out the synthesis reaction with elemental boron, and the reaction product is boron trifluoride gas (BF 3 ).

[0039] Analyzing the composition of the gas at the outlet of the reactor, the gas contains a small amount of hydrogen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com