Inclined plate separate film biological reactor

A membrane bioreactor, a separate technology, applied in sustainable biological treatment, osmotic/dialysis water/sewage treatment, aerobic process treatment, etc. and other problems, to achieve the effect of convenient management and operation, reducing operating costs and increasing sludge load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

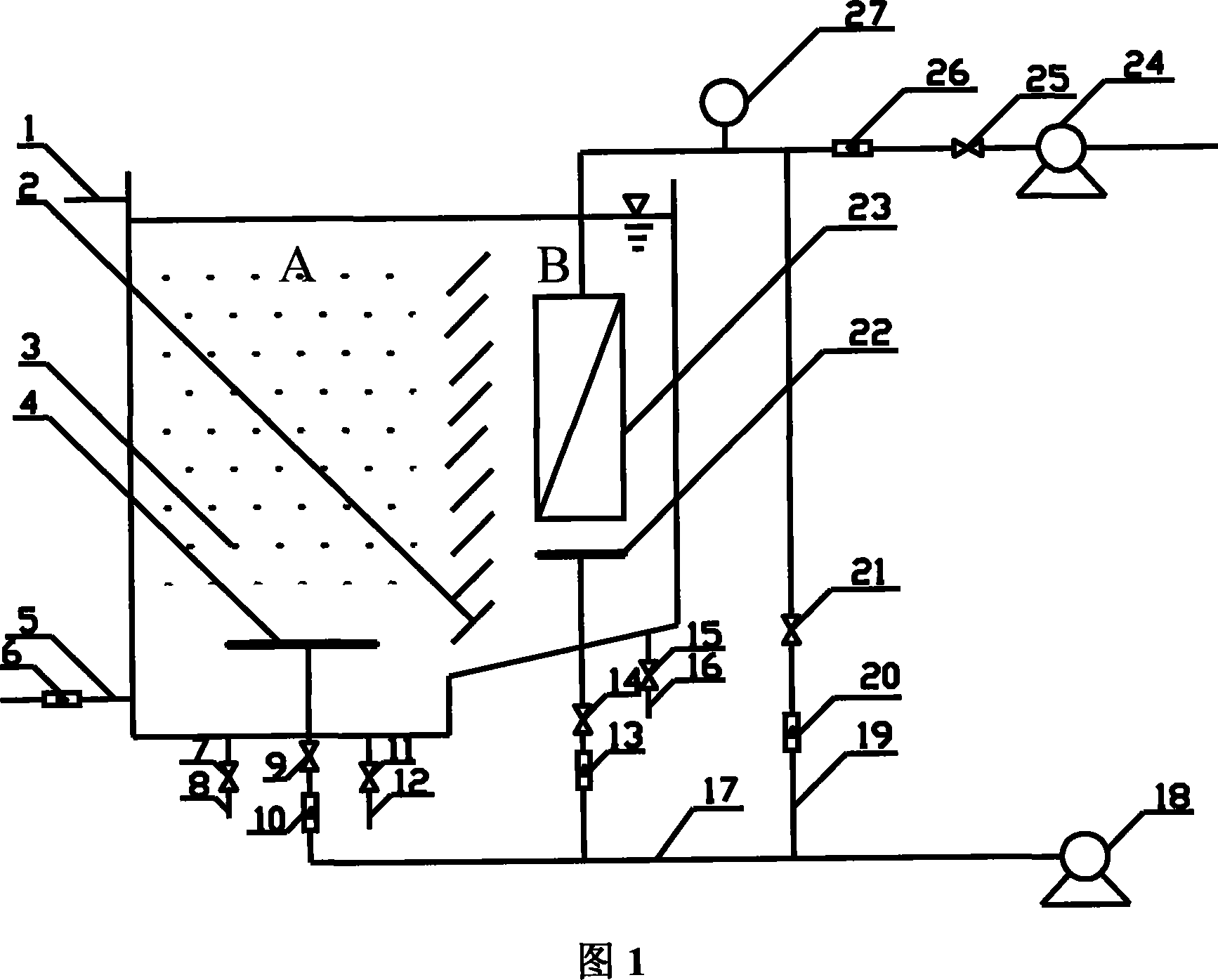

[0023] Referring to Fig. 1, a preferred embodiment of the present invention is described as follows in conjunction with accompanying drawing: sewage enters biological contact oxidation zone (A) through water inlet pipe (5), and the inner chamber of biological contact oxidation zone is equipped with suspended filler or suspended filler; The aeration of the aeration tube in the oxidation zone provides the oxygen required for the biological reaction while increasing the hydraulic power, so that the sewage is fully mixed; the sewage enters the membrane separation zone (B) through the sloping plate (2), and part of the sludge settles under the barrier effect of the sloping plate Return to the biological contact oxidation zone (A), so that the biomass of the sewage in the membrane separation zone (B) is lower than the biomass of the sewage in the biological contact oxidation zone (A); the aeration of the aeration head (22) in the membrane separation zone Under the action, the sewage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com