Engine control module environment durability test all-purpose platform and test method

A technology of control module and general platform, which is applied in the direction of engine testing, machine/structural component testing, measuring devices, etc. It can solve the problem of inability to configure analog signal types and parameters on site, inability to adapt to automotive EFI engine technology, and inability to set automatic Issues such as cycle strategy to achieve the effect of improving test reliability, shortening test process, great flexibility and scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] specific implementation plan

[0029] The test system will be further elaborated below in conjunction with the accompanying drawings:

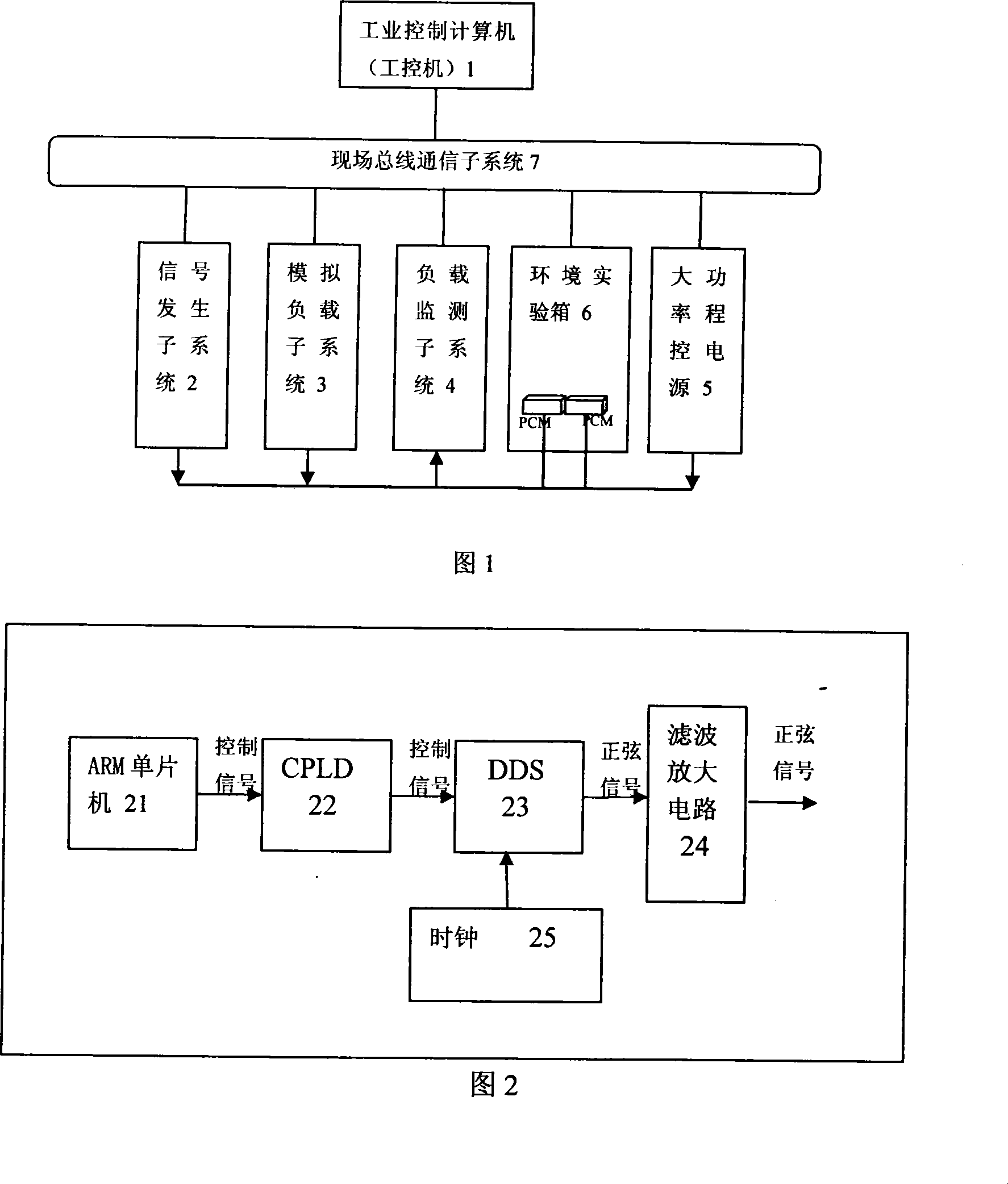

[0030]The industrial control computer (industrial computer) 1 is the core of the entire test system and the main platform for man-machine communication, on which the control software and test software of the upper computer run. This system adopts Advantech's industrial computer, and installs a communication protocol conversion card. It mainly uses the field bus communication subsystem 7 to connect the signal generation subsystem 2, the analog load subsystem 3, the load monitoring subsystem 4, the program-controlled high-power power supply 5, and the environment. The experimental boxes 6 are connected to form a communication network to realize the sending and receiving of information. At the same time, the industrial computer 1 is equipped with a conditioning amplifier, A / D card, D / A card, and uses application software developed by Visu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com