Semiconductor light emitting device and method for fabricating same

一种发光器件、半导体的技术,应用在半导体器件、半导体激光器、半导体/固态器件零部件等方向,能够解决妨碍膜中Mg活化、受主浓度和空穴密度减少等问题,达到抑制增加、抑制元件操作电压、抑制扩散的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

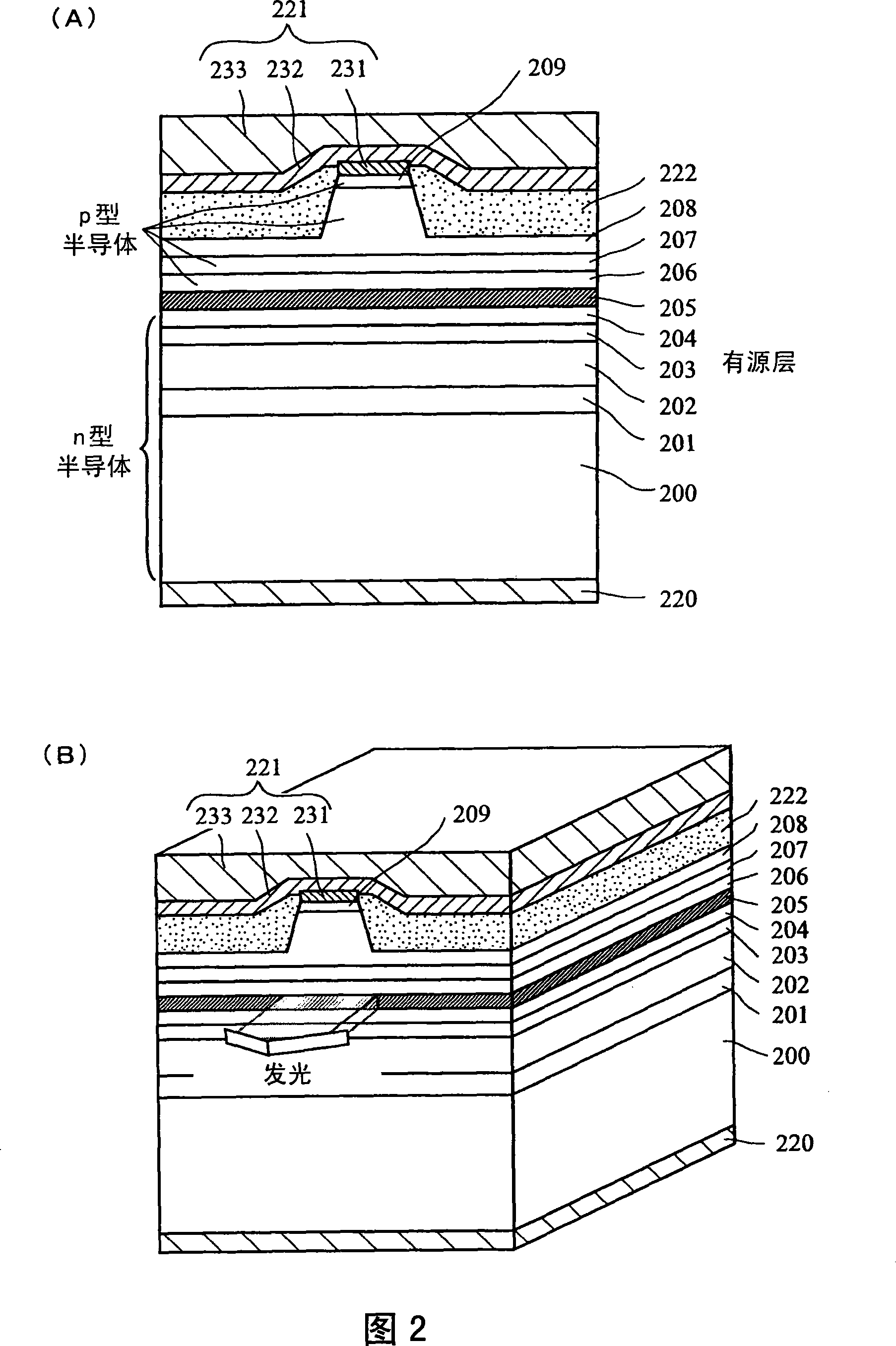

[0051] 2(A) is a schematic sectional view of a semiconductor laser element of the semiconductor laser device used in Example 1 according to the present invention.

[0052] The insulating layer 222 is disposed on the periphery of the protruding portion of the ridge structure to form a current confinement path structure having one electrode electrically connected only to the top of the protruding portion, thereby limiting the portion through which current passes. The current limiting path structure enables approximate control of the spot shape of the emitted light. The insulating layer 222 consists of 1 x 10 17 / cm 3 or above concentrations of hydrogen atoms. The width of the protruding portion of the ridge structure is approximately 1.6 μm, and the length of the resonant cavity is 600 μm. The element undergoes an AR (anti-reflection) coating on the front side and a HR (high reflection) coating on the back side.

[0053] The P-type conductive layer is doped with from 1×10 1...

example 2

[0084] A method and assembly equipment for manufacturing a nitride semiconductor laser device according to the present invention will be described.

[0085] Referring to FIG. 10 , the assembly device has a front chamber 101 and a working chamber 102 . The front chamber 101 makes it possible to introduce the necessary components for assembly into the working chamber 102 without opening the working chamber 102 to the atmosphere. For this purpose, the front chamber 101 has means 103 for introducing purge gas. The working chamber 102 has therein an assembly mechanism 104 for assembling the nitride semiconductor laser device, thereby enabling the assembly work to be performed in an externally isolated sealed space. Between the front chamber 101 and the working chamber 102 there is a transfer device (not shown) for transferring the necessary components required for assembly. The front chamber 101 and the working chamber 102 are separated by a door 109 .

[0086] The working chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com