Two-phase flow integrated quartz resistance furnace

A resistance furnace and phase flow technology, applied in the direction of silicon oxide, silicon dioxide, etc., can solve the problems of rising cable temperature, humid working environment, increasing contact resistance, etc., to reduce resistance loss, increase operating voltage, and reduce contact The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

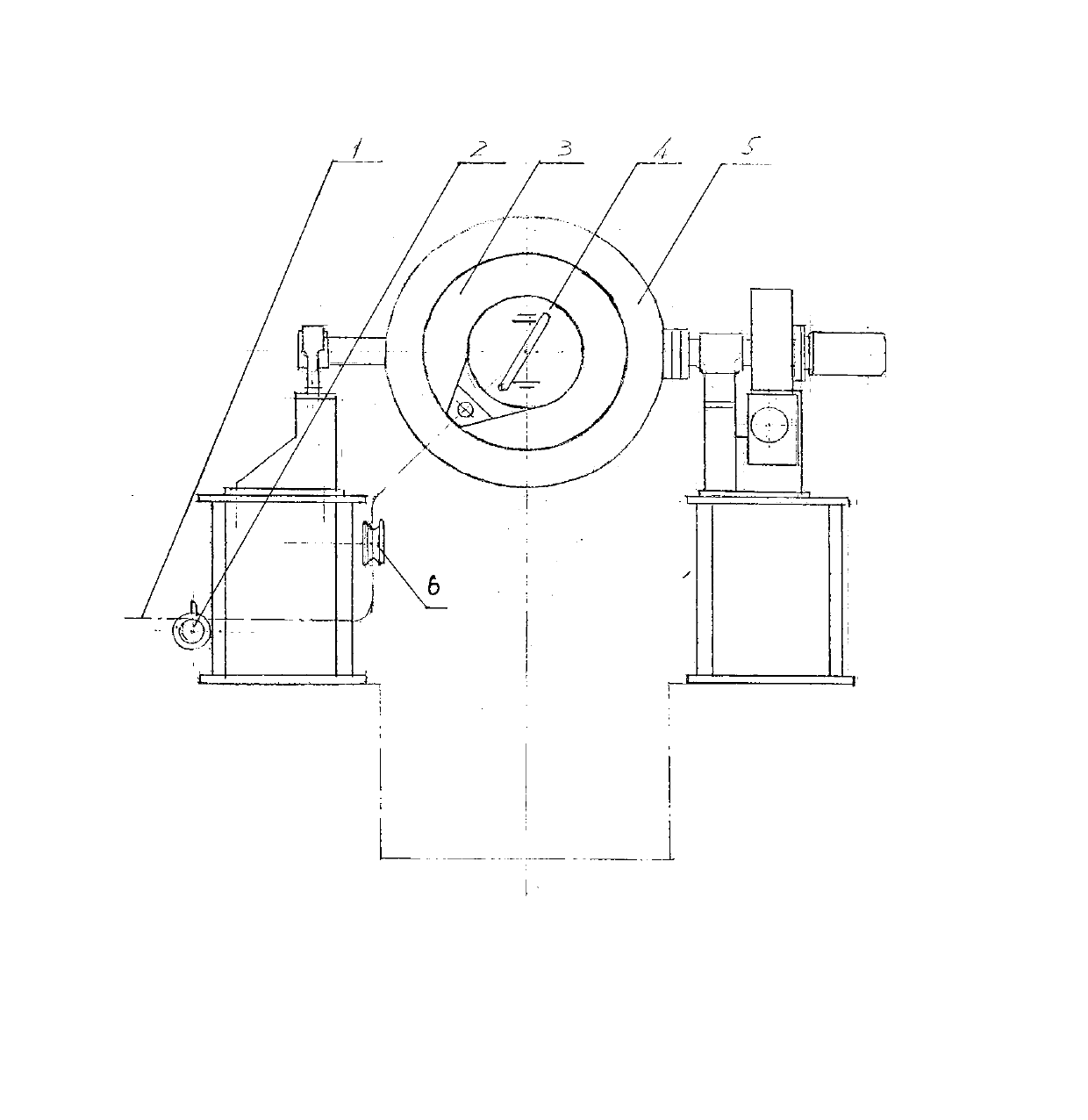

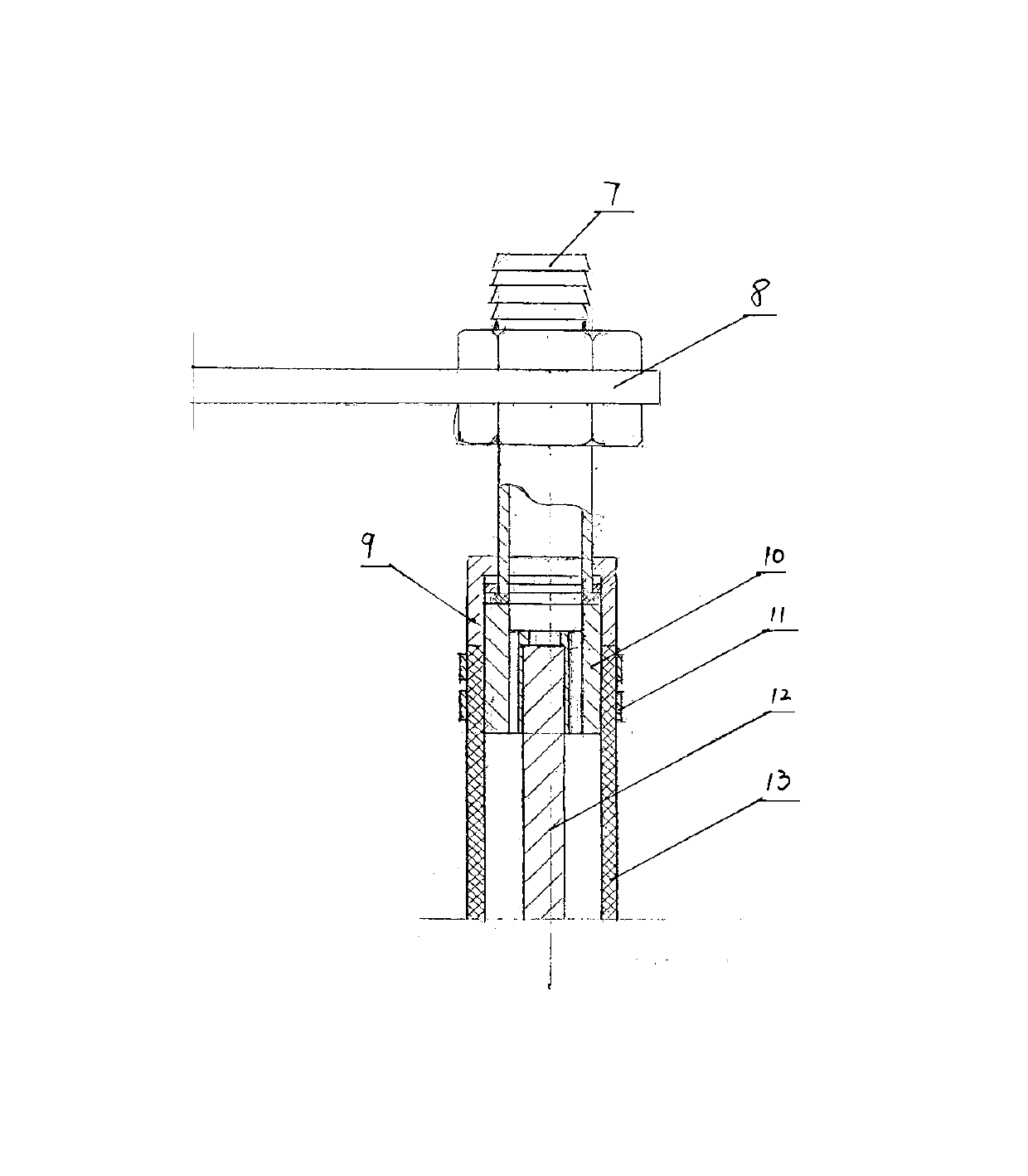

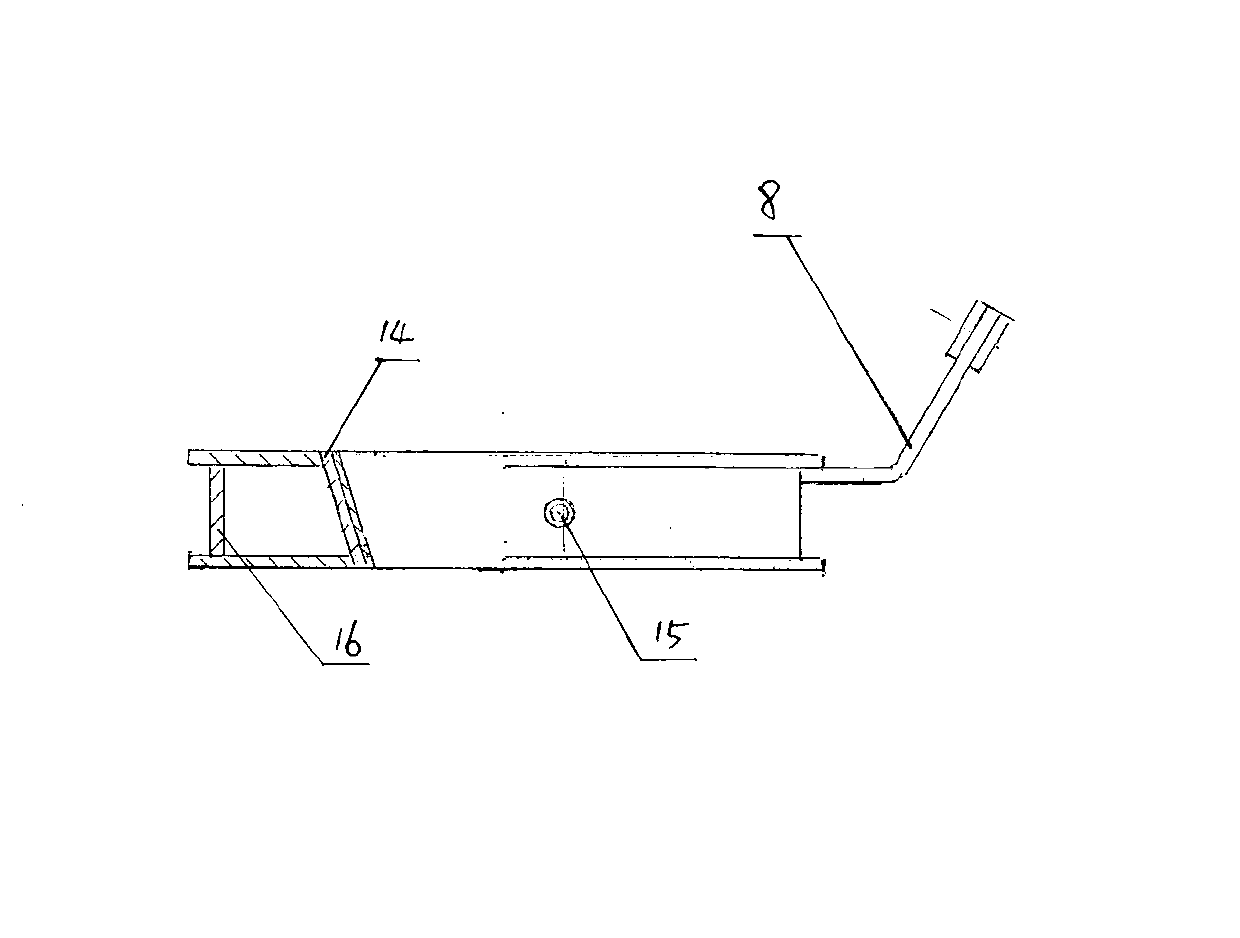

[0013] A two-phase flow integrated quartz resistance furnace, including a circular metal cylinder 5 mounted on a rotating shaft and capable of rotating 180 degrees, a graphite electrode is longitudinally arranged in the cylinder 5, and the two ends of the graphite electrode pass through the graphite electrode. The electrode sleeve 14 is connected with the composite electrode 8 arranged at both ends of the cylinder, the composite electrode 8 is connected with the low-voltage side of the transformer in front of the furnace through the cable 1, and the furnace cover cooling water drum 3 is arranged around the composite electrode 8, and the graphite electrode sleeve 14 is surrounded by a water-cooling jacket 4, the water-cooling jacket 4 includes an inner ring and an outer ring 16, the inner ring is composed of a graphite electrode sleeve 14, the composite electrode 8 made of copper-iron composite material is fixed to the outer ring 16, and the cable 1 is water-cooled Cables, water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com