Stable recombinant human endostain preparation and preparing method thereof

An endostatin and vascular endothelium technology, which is applied in the field of recombinant human endostatin preparation and preparation technology, can solve the problems such as no relevant reports and unsatisfactory stability, and achieves simple preparation process, maintaining stability, and formulating a formula. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

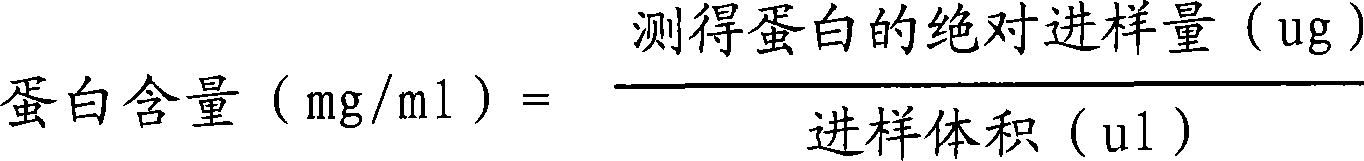

Method used

Image

Examples

preparation Embodiment 1

[0036] Use 30mM acetic acid-sodium acetate buffer system with pH5.5±0.5 to perform ultrafiltration dialysis on the purified recombinant human endostatin protein solution, and prepare 151.5ml recombinant human endostatin solution with a concentration of 9.9mg / ml 60ml of 20% mannitol and 7.5ml of 20% sucrose solution were added, 2.98ml of 1.5M acetic acid-sodium acetate buffer solution with a pH of about 5.5 was added, and water for injection was added to 300ml. Sterilize and filter through a 0.22 μm microporous membrane, dispense into prefilled syringes, and store at 4°C.

preparation Embodiment 2

[0038] Use 30mM acetic acid-sodium acetate buffer system with pH5.5±0.5 to perform ultrafiltration dialysis on the purified recombinant human endostatin protein solution, and prepare 90.9ml recombinant human endostatin solution with a concentration of 9.9mg / ml , add 60ml of 20% mannitol, add 4.20ml of acetic acid-sodium acetate buffer solution of about 1.5M pH5.5, and add water for injection to 300ml. Sterilize and filter through a 0.22μm microporous membrane, pack into vials, the liquid level is 1-1.5cm higher than the bottom of the bottle, add butyl rubber stopper, place the liquid in a freeze-drying box, and the temperature of the product drops to - 40°C, keep it for 3-4 hours, vacuumize, heat the partition, raise the temperature of the product to -20°C, keep it for 8 hours, continue heating to raise the temperature to 25°C, keep it for 6 hours, until the vacuum degree does not change much , take it out after vacuum pressing, and roll the cap.

preparation Embodiment 3

[0040] Use 30mM acetic acid-sodium acetate buffer system with pH5.5±0.5 to perform ultrafiltration dialysis on the purified recombinant human endostatin protein solution, and prepare 151.5ml recombinant human endostatin solution with a concentration of 9.9mg / ml , add 60ml of 20% mannitol and 15ml of 20% sucrose solution, add 2.98ml of 1.5M acetic acid-sodium acetate buffer solution with a pH of about 5.5, and add water for injection to 300ml. Sterilize and filter through a 0.22μm microporous membrane, pack into vials, the liquid level is 1-1.5cm higher than the bottom of the bottle, add butyl rubber stopper, place the liquid in a freeze-drying box, and the temperature of the product drops to - 40°C, keep it for 4-5 hours, vacuumize, heat the partition, raise the temperature of the product to -25°C, keep it for 10 hours, continue heating to raise the temperature to 30°C, keep it for 4 hours, until the vacuum degree does not change much , take it out after vacuum pressing, and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com