Process for preparing n-propanol by hydrogenation of propionaldehyde with cu-zn catalyst

A production process and a technology for n-propanol, applied in the chemical industry, can solve the problems of easy deactivation of cobalt-based catalysts, side reactions of reduction into hydrocarbons, high price, etc., and achieve the effects of low cost, few side reactions, and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

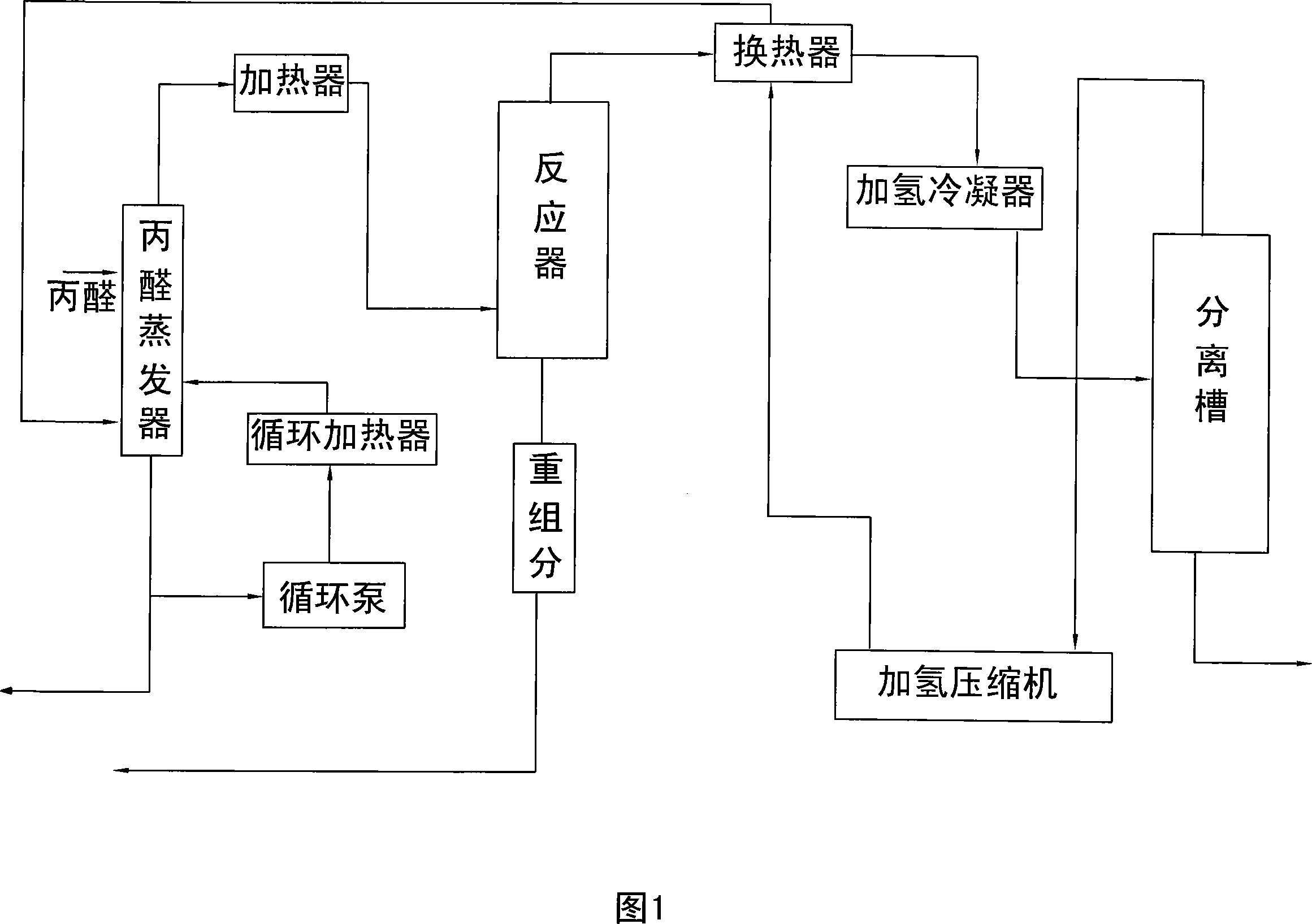

Method used

Image

Examples

Embodiment 1

[0020] The molar ratio of propionaldehyde to hydrogen is 1:1, and the composition of the copper-zinc catalyst is: 29.66% of copper oxide, 70% of zinc oxide, 0.07% of aluminum oxide, 0.07% of ferric oxide, and 0.2% of sodium oxide. %.

[0021] Propionaldehyde gas phase hydrogenation reaction temperature is 160°C, reaction space velocity is 0.4h -1 , the hydrogen oil ratio is 3500.

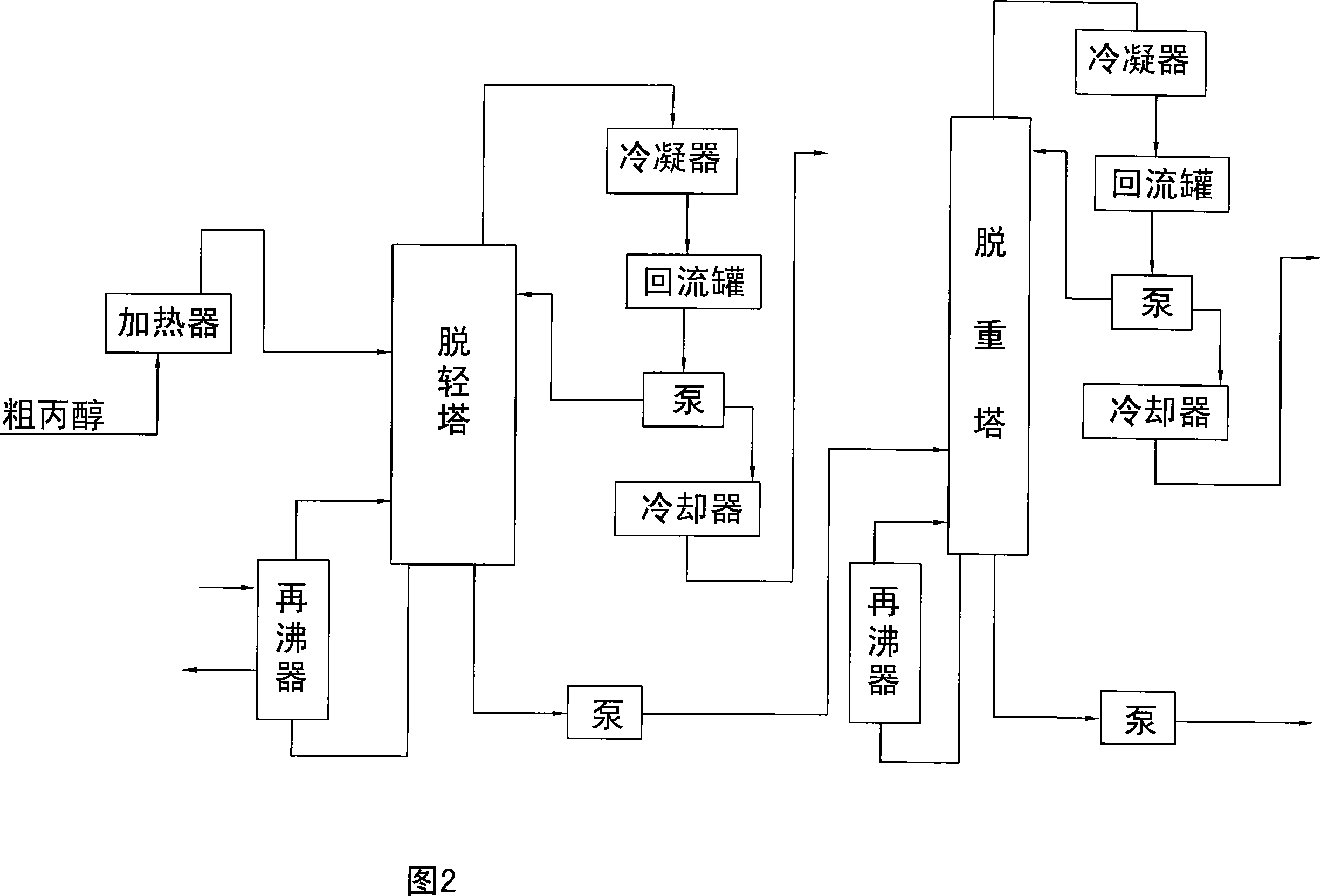

[0022] Crude propanol enters the delightening tower to remove light components, the temperature at the bottom of the delightening tower is 90°C, and the temperature at the top of the tower is 76°C. The heavy components are removed in the weight-removing tower, the temperature at the bottom of the weight-removing tower is 92°C, and the temperature at the top of the tower is 94°C.

[0023] The purity of the product n-propanol is 99.76%.

Embodiment 2

[0025] The molar ratio of propionaldehyde to hydrogen is 1:2, and the composition of the copper-zinc catalyst is: 31.3% copper oxide, 68.3% zinc oxide, 0.11% aluminum oxide, 0.09% iron sesquioxide, and 0.2% sodium oxide. %.

[0026] Propionaldehyde gas phase hydrogenation reaction temperature is 170°C, reaction space velocity is 0.5h -1 , the hydrogen oil ratio is 4500.

[0027] Crude propanol enters the delightening tower to remove light components, the temperature at the bottom of the delightening tower is 92°C, and the temperature at the top of the tower is 80°C. The heavy components are removed in the weight-removing tower, the temperature at the bottom of the weight-removing tower is 98°C, and the temperature at the top of the tower is 96°C.

[0028] The purity of the product n-propanol is 99.85%.

Embodiment 3

[0030] The molar ratio of propionaldehyde to hydrogen is 1:3, and the composition of the copper-zinc catalyst is: 45% copper oxide, 54.5% zinc oxide, 0.06% aluminum oxide, 0.14% iron oxide, and 0.3% sodium oxide. %.

[0031] Propionaldehyde gas phase hydrogenation reaction temperature is 180°C, reaction space velocity is 0.55h -1 , the hydrogen oil ratio is 4800.

[0032] Crude propanol enters the delightening tower to remove light components, the temperature at the bottom of the delightening tower is 98°C, and the temperature at the top of the tower is 90°C. The heavy components are removed in the weight-removing tower, the temperature at the bottom of the weight-removing tower is 100°C, and the temperature at the top of the tower is 105°C.

[0033] The purity of the product n-propanol is 99.88%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com