Current sensor

A current sensor and current sampling technology, which is applied in voltage/current isolation, measuring current/voltage, instruments, etc., can solve the problems of relay protection device misoperation, secondary current distortion, and narrow frequency band, so as to achieve easy installation and Maintenance, wide dynamic range, not easy to burn out effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

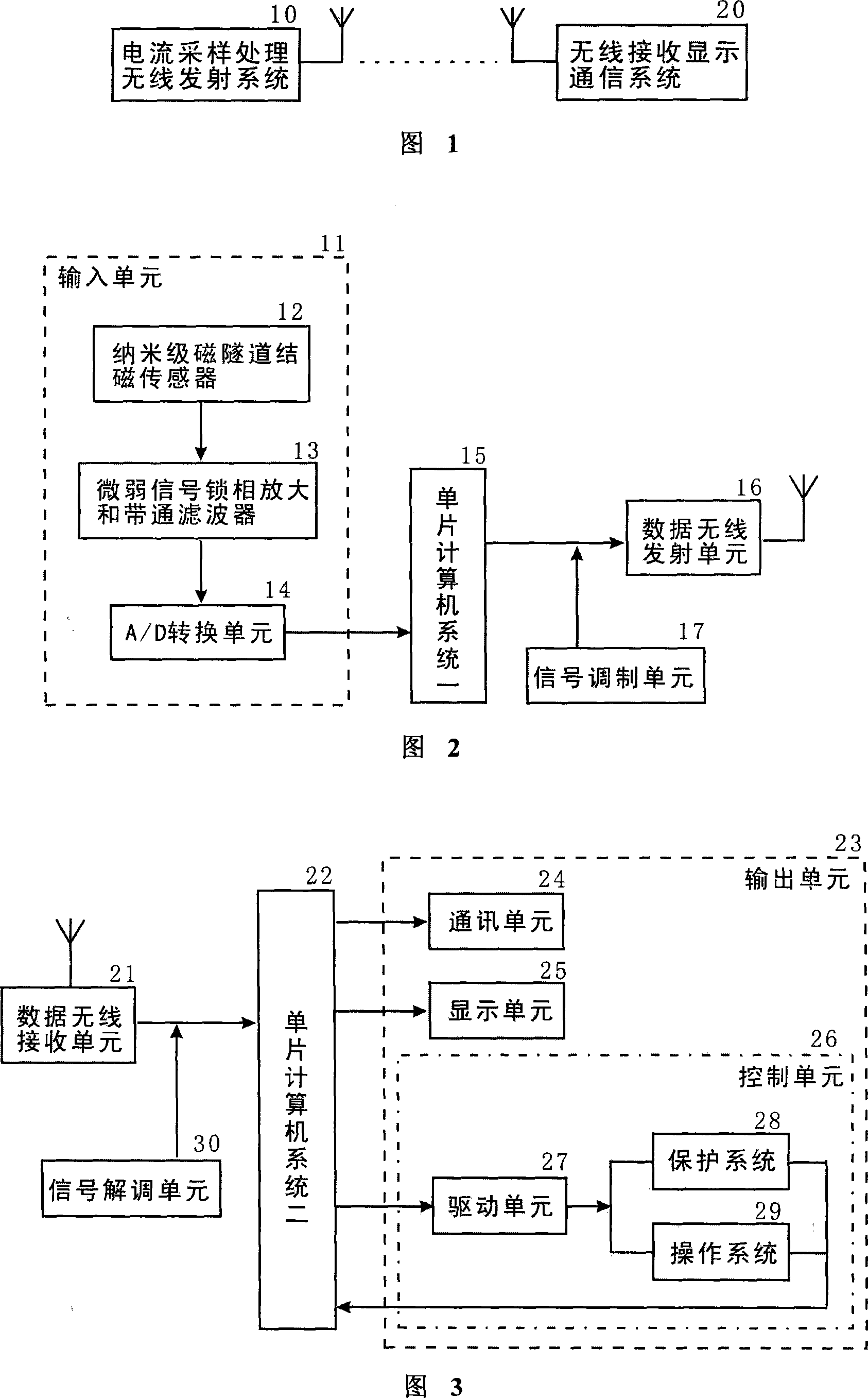

[0038] Embodiment: As shown in FIG. 1, a current sensor includes a current sampling and processing wireless transmitting system 10, and a wireless receiving and displaying communication system 20, and the current sampling and processing wireless transmitting system 10 and the wireless receiving and displaying communication system 20 pass through Connect wirelessly.

[0039] As shown in Figure 2, the current sampling processing wireless transmitting system 10 comprises an input unit 11, a single-chip computer system one 15, and a data wireless transmitting unit 16 connected in sequence; the input unit 11 comprises a nanoscale magnetic tunnel junction magnetic sensor 12 connected in sequence, Weak signal lock-in amplification and bandpass filter 13, A / D conversion unit 14. The A / D conversion unit 14 is connected to a single-chip computer system 15 . Also, a signal modulating unit 17 is connected to the data wireless transmitting unit 16 .

[0040] As shown in FIG. 3 , the wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com