Monolayer polarizing and direction-matching function conformity membrane as well as method for manufacturing the same and LCD containing the same

A liquid crystal display, polarized light technology, applied in optics, instruments, optical components, etc., can solve the problems of difficult acquisition of TAC film, time-consuming production, easy cracking into small molecules, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

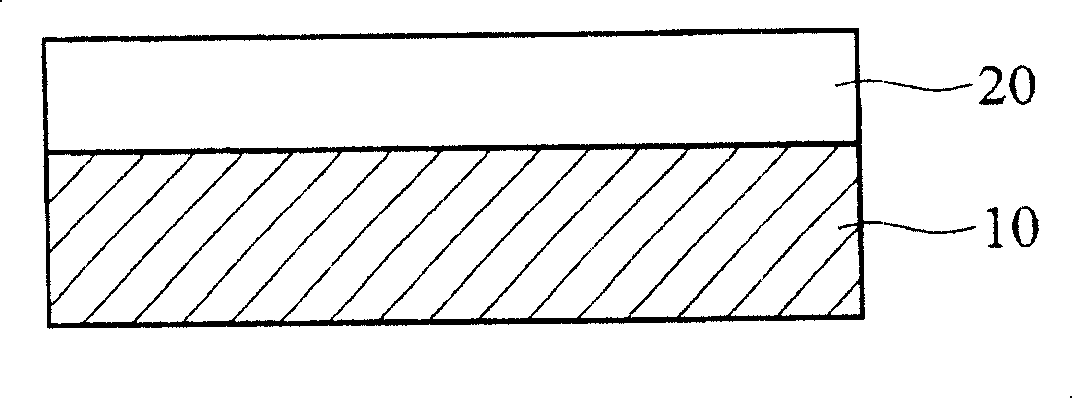

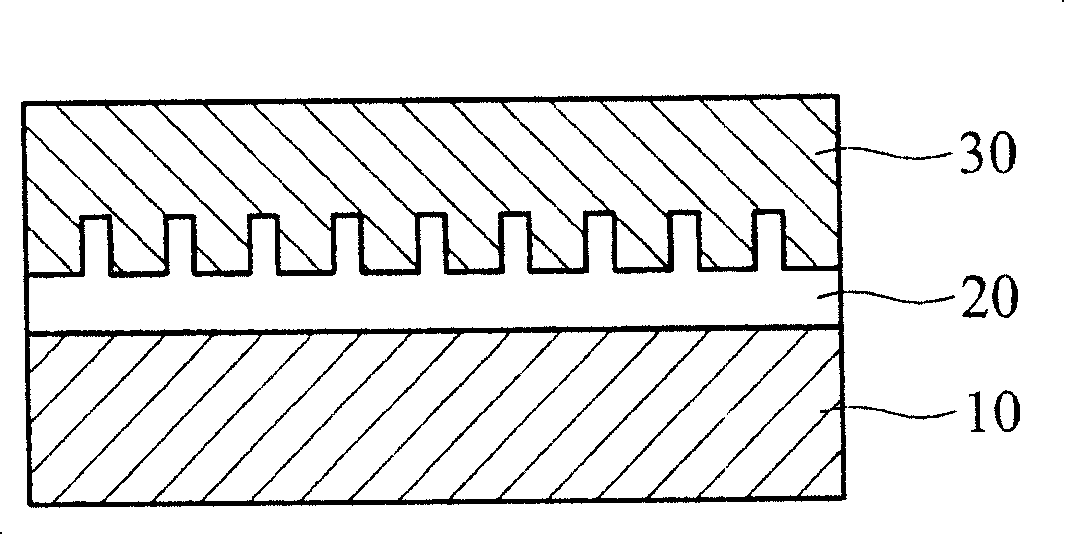

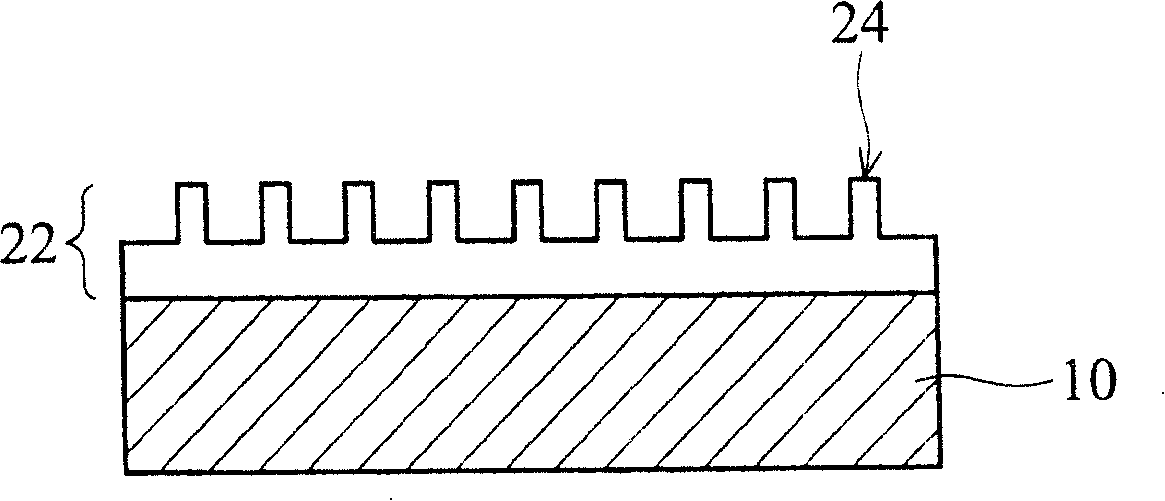

Method used

Image

Examples

Embodiment 1

[0061] Mix the polymerizable nematic liquid crystal uniformly into the solvent toluene, the liquid crystal is 30% by weight relative to the solvent toluene, and add 5% dichroic dye relative to the content of SLM 90519 , the material was coated on a glass substrate coated with ITO electrodes by spin coating method. After the solvent is removed by baking, it is put into the embossing machine, and the embossing process is carried out with a mold with multiple periodic strip-shaped concave-convex structures. The period of the surface structure of the mold is 1.8 μm, the depth is 0.2 μm, and the overall width of the film layer is 3cm, length 4cm, pressure value of imprinting process is 1.5bar, temperature is 100°C, and time is 20 minutes. After embossing, UV light is used for cross-linking (curing), and then the film is released to complete the single-layer polarizing and alignment function integrated film of Example 1 of the present invention. The film thickness of the single-lay...

Embodiment 2~7

[0063] The difference between the single-layer polarizing and alignment functional integrated films of Examples 2-7 and Example 1 is that the periods of the mold surface structures used in Examples 2-7 are 3 μm, 10 μm, 250 nm, 574 nm, 697 nm and 804 nm, and other process conditions And use material all is identical with embodiment 1. Similarly, the polarization degree and average transmittance were tested for the single-layer polarizing and alignment functional integrated films of Examples 2-7, and the test results are shown in Table 1.

[0064] Table 1 Polarization degree and transmittance of single-layer polarizing and alignment functional integrated films of Examples 1-7

[0065] mold pattern cycle

Embodiment 8

[0067] The single-layer polarizing and alignment functional integrated films prepared in Example 1 are placed on the transparent substrate, and the strip-shaped protrusion structures on the two substrates are vertically attached to each other and packaged to form a liquid crystal cell ( cell), injected twisted nematic (TN) liquid crystal (MLC-13900-100, Merck), driven with a voltage of 0-12 volts, and measured its wear and tear under different applied voltages with a red He-Ne laser (633nm). Transparency, the results are shown in Figure 11, the contrast ratio of the obtained liquid crystal display is 19:1.

[0068] From the results in Figures 10 and 11, it can be seen that the polarization degree and average transmittance of the single-layer polarizing and alignment functional integrated film of the present invention can meet the requirements for polarizers in liquid crystal displays, and the single-layer film of the present invention can The integrated film with polarizing an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com