A die-cast steel chassis masonry material and its manufacturing method

A manufacturing method and chassis technology, applied in the field of new die-cast steel chassis masonry materials and its manufacturing, to achieve uniform particle size, stable quality, and prevent chassis leakage accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

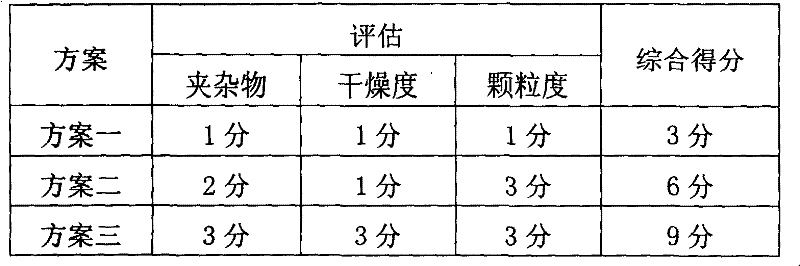

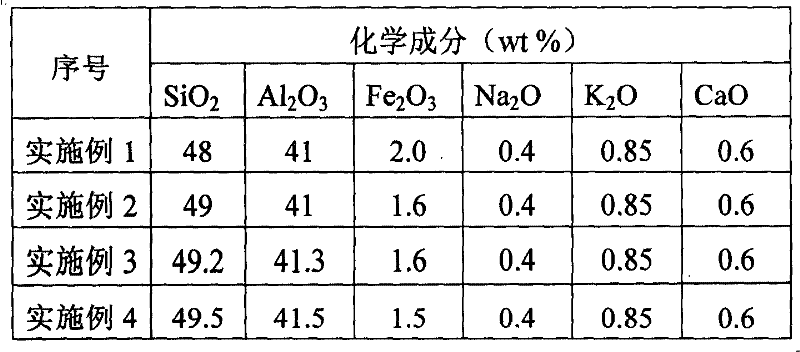

Embodiment 1

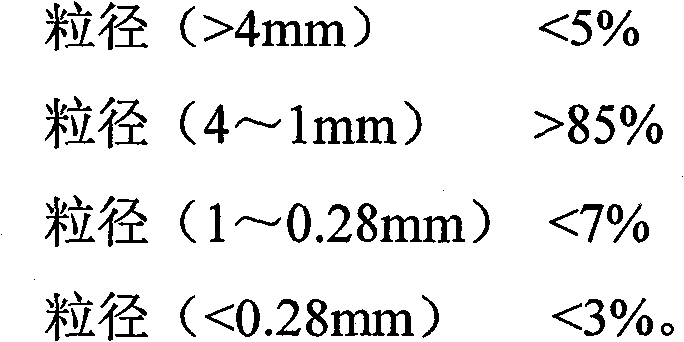

[0047] First of all, the sorted waste clay soup brick raw materials are subjected to primary magnetic separation with a belt magnetic separator, and the large block raw materials after magnetic separation are processed into small pieces of 20*20cm by a jaw crusher, and then sent to the Double-roll crusher, processed into small particles with a particle size of ≤4mm, and then a three-roll magnetic separator with a magnetic induction intensity of 3000 is used to conduct secondary magnetic separation on the small particles, and then the small particles after magnetic separation are separated by the second elevator The granules are sent to the vibrating sieve, and sieved to obtain raw materials with a particle size of 4-1mm. Then add 1% white carbon black anti-high temperature additive to the raw materials of the specifications, knead and stir in the kneader, dry in a baking kiln at 150°C, and finally inspect and pack to obtain a molded steel chassis masonry Material.

Embodiment 2

[0049] Implementation method is the same as Example 1, wherein the add-on of white carbon black is 1.5%.

Embodiment 3

[0051] Implementation method is the same as Example 1, wherein the add-on of white carbon black is 2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com