Delayed coking treatment method for waste plastics and treatment device thereof

A technology of delayed coking and waste plastics, applied in plastic recycling, preparation of liquid hydrocarbon mixture, petroleum industry, etc., can solve the problems of small application range, high input cost, complicated process, etc., to reduce secondary pollution and low input cost , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

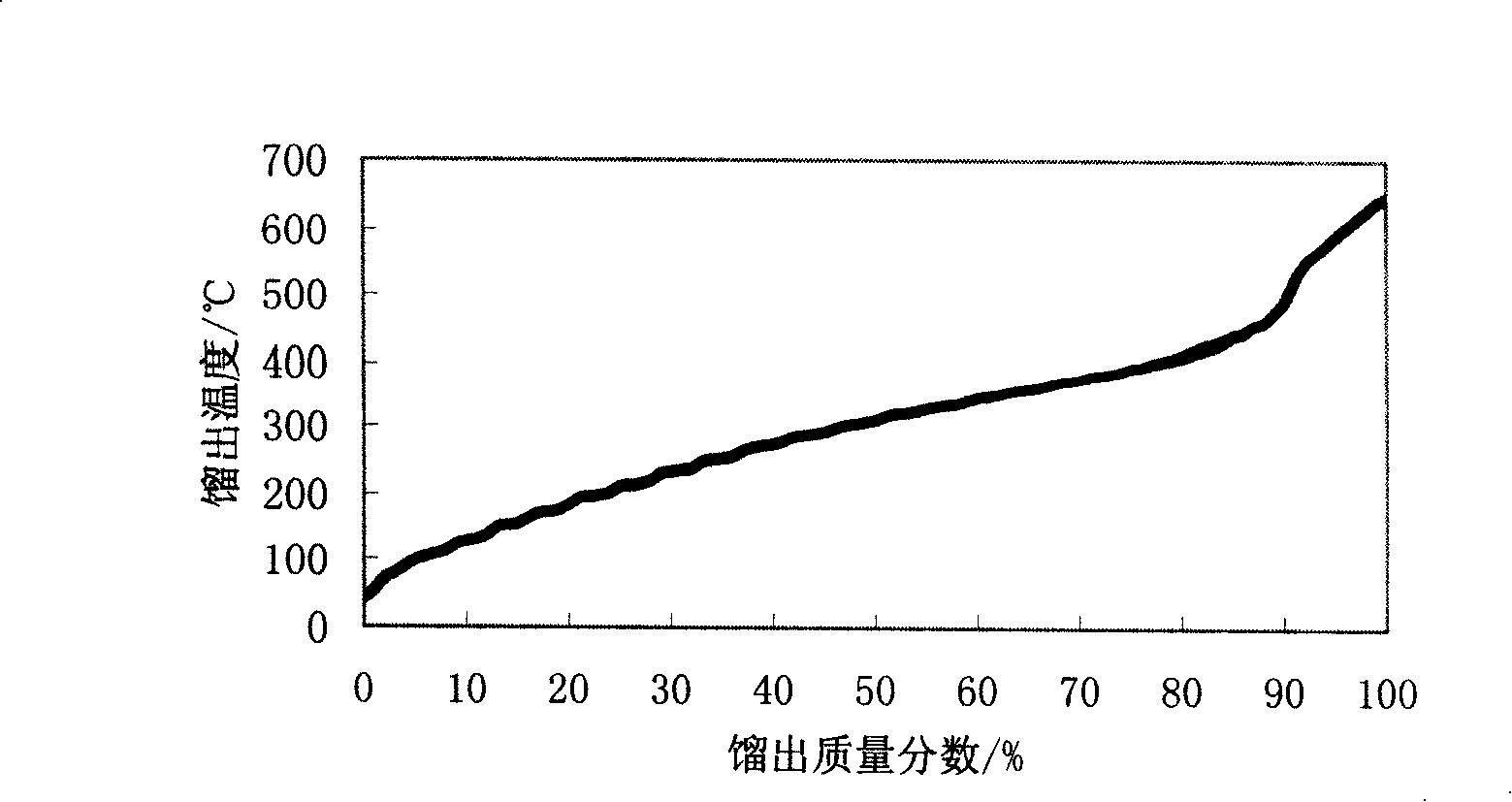

[0043] The raw material is waste plastic (PE), crushed to less than 0.5mm, and preheated to 300°C after removing impurities. Then the temperature is rapidly raised to 500°C in the heating furnace. The product yields obtained after reaction and fractionation are shown in Table 1.

[0044] Table 1 waste plastics delayed coking product yield (wt%)

[0045] raw material

liquid product yield

Solid product yield

gas product yield

waste plastic

90.8%

0.67%

8.95%

[0046] Referring to the chromatographic analysis method of biomass tar, n-hexane, benzene, and absolute ethanol are used in sequence to elute the aliphatic hydrocarbons, aromatic hydrocarbons, and polar components in the liquid product, drive off the solvent, and weigh. Obtain the content of each component in the sample, and use the difference method to obtain the asphaltene content. The results are shown in Table 2. It can be seen that most of the plastic tar is ali...

Embodiment 2

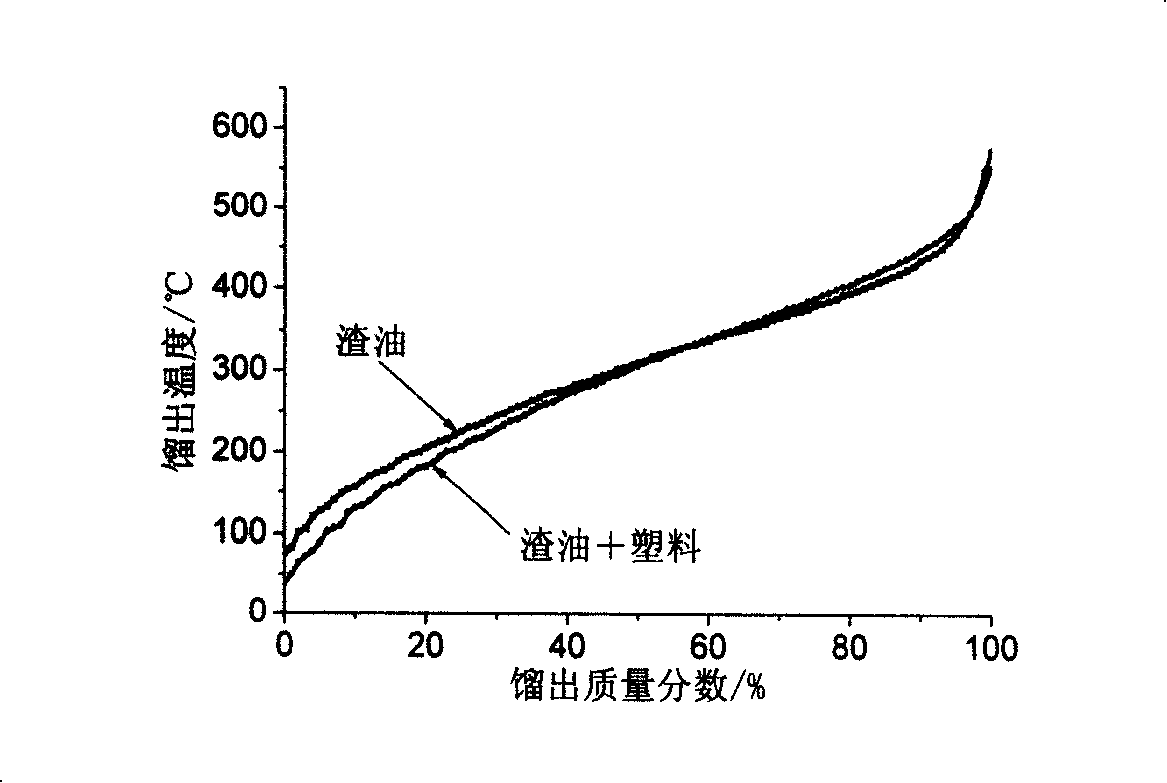

[0054] The raw material is 10% pretreated waste plastic (PE) mixed with 90% residual oil (vacuum residual oil from Shanghai Petrochemical 1 million tons / year delayed coking unit, the composition is 60% sand light oil + 40% Oman oil ), the mixture was preheated to 200°C and then rapidly heated to 500°C in the heating furnace. After a reaction time of 2 to 3 hours, the product yields obtained are shown in Table 4.

[0055] Table 4 Waste Plastics Mixed Residue Delayed Coking Product Yield (wt%)

[0056] raw material

liquid product yield

Solid product yield

gas product yield

waste plastic

66.45

21.04

12.51

[0057] Adopt the same experimental analysis method as Example 1 to carry out the distillation range analysis of liquid product. The results are shown in Table 5 below and image 3 .

[0058] Table 5 Tar fraction content / % of co-refined plastics and residual oil

[0059]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com