Method for preparing powdered phosphatidyl serine

A powdered phosphatidylserine and serine technology, which is applied in the field of compound preparation, can solve the problems of high cost, large investment in equipment, and difficult to guarantee the reaction conversion rate, etc., and achieve the effect of low cost, small investment in equipment, and reduction of by-products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

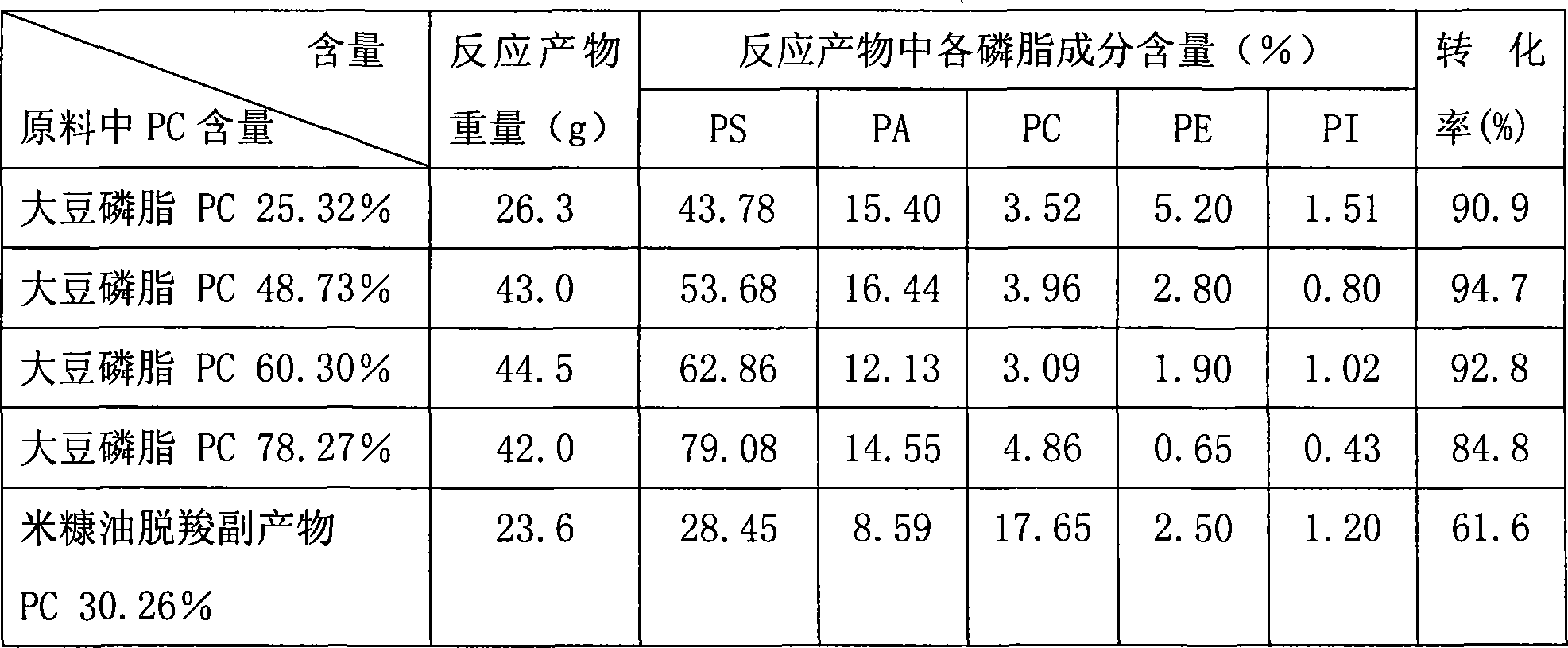

[0020] Weigh 50 g of soybean lecithin with a phosphatidylcholine (PC) content of 25.32% (powdered, commercially available). Add 400ml of water and stir, heat at 50°C, and disperse evenly after half an hour. In addition, weigh 100g of L-serine, CaCL 2 3.2g, 12g sodium acetate, 1.4ml acetic acid, add 400ml water and stir to dissolve, the measured pH is 5.0, after mixing the two systems, add PLD0.18g, the activity unit is 1000units / g. Start timing, the reaction temperature is 40° C. to 50° C., and the conversion rate is detected after 18 hours of reaction. After complete conversion, add ethyl acetate for extraction, then concentrate the extract, add 0.5mg VE as an antioxidant, and finally treat the mixed phospholipids with acetonitrile to obtain 26.3g powdered PS with a PS content of 43.78%. See Schedule.

Embodiment 2

[0022] Weigh 50g of soybean lecithin with a phosphatidylcholine (PC) content of 48.73% (granular, commercially available), add 300ml of water and stir, heat at 20°C, and disperse evenly after half an hour. In addition, weigh 200g of L-serine, CaCL 2 6.4g, 22.2g sodium acetate, 2.8ml acetic acid, add 300ml water and stir to dissolve, the measured pH is 5.0, after mixing the two systems, add 0.80g PLD, the activity unit is 1500units / g. Start timing, the reaction temperature is 40° C. to 50° C., and the conversion rate is detected after 20 hours of reaction. After complete conversion, add n-hexane for extraction, then concentrate the extract, add 2.5 mg VC as an antioxidant, and finally treat the mixed phospholipids with ethanol to obtain 43.0 g powdered PS with a PS content of 53.68%.

Embodiment 3

[0024] Weigh 50g of soybean lecithin with a phosphatidylcholine (PC) content of 60.30% (block, commercially available), add 400ml of water and stir, heat at 50°C, and disperse evenly after half an hour. In addition, weigh 300g of L-serine, CaCL 27.9g, 27.4g sodium acetate, 3.5ml acetic acid, add 400ml water and stir to dissolve, the measured pH is 5.2, after mixing the two systems, add 1.10g PLD, the activity unit is 1500units / g. Start timing, the reaction temperature is 40° C. to 50° C., and the conversion rate is detected after 20 hours of reaction. After complete conversion, add n-hexane for extraction, then concentrate the extract, add 2.5mg VC as an antioxidant, and finally treat the mixed phospholipids with ethanol to obtain 44.5g powdered PS with a PS content of 62.86%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com