Technique for preparing high solid-content low oil-water ratio water-soluble polymer reversed phase emulsion

A technology of water-soluble polymer and inverse microemulsion, which is applied in the field of low oil-water ratio inverse microemulsion preparation and high solid content. phase microemulsion etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The synthesis of embodiment 1 stabilizer

[0018] Weigh 5 grams of OP-10, dissolve it with 30 milliliters of acetone, then add 10 milliliters of toluene, raise the temperature to 50-55 °C, add APS initiator solution and 5 grams of butyl acrylate dropwise to the reaction system at the same time, after the addition is complete, keep it warm After 3-5 hours, the reaction is stopped, and the organic solvent and unreacted butyl acrylate are removed to obtain a self-made stabilizer. The amount of APS accounts for 0.2% to 0.3% of the amount of butyl acrylate.

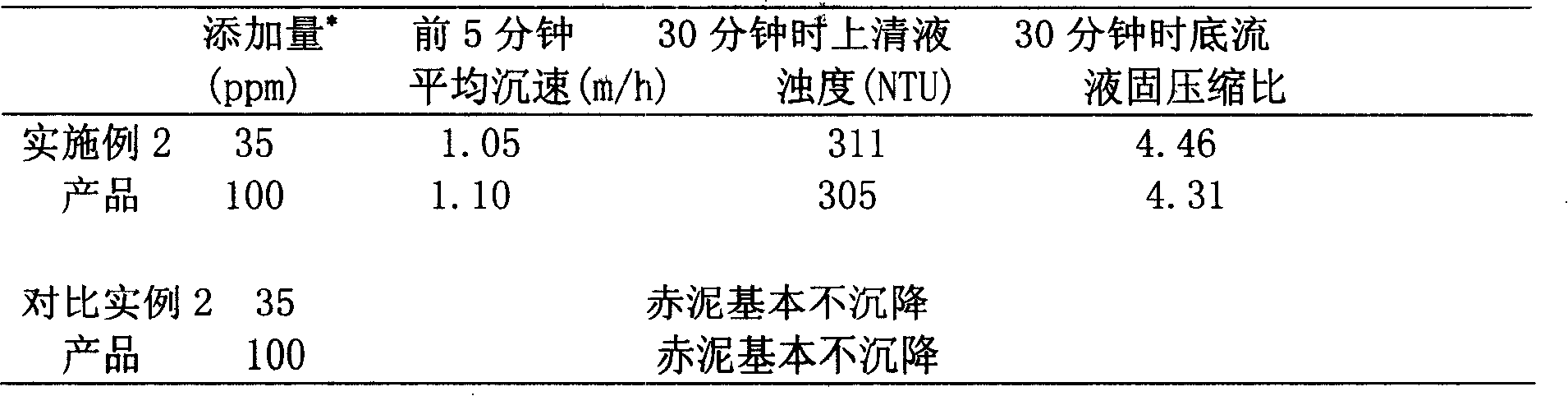

Embodiment 2

[0019] The preparation of the sodium acrylate-acrylamide copolymer inverse microemulsion of embodiment 2 solid content 40%, oil-water ratio 0.5

[0020] In the 100ml three-necked bottle that condensing pipe, air guide tube and mechanical stirring are housed, lead high-purity nitrogen, to discharge oxygen, and add 7.44 gram 32# white oils, 4.5 gram emulsifier SPAN80, gained in 0.56 gram embodiment 1 self-made Stabilizer, warming up to 50°C, after vigorous stirring for 10 minutes, add 23 grams of 56% sodium acrylate-acrylamide (weight ratio of sodium acrylate / acrylamide 1:4) aqueous solution, continue stirring for half an hour, and then slowly add APS aqueous solution (0.03 gram of APS is dissolved in 1 gram of water), when the APS aqueous solution is added to about half of the total amount, slowly start dripping ferric chloride aqueous solution (0.06 gram of ferric chloride is dissolved in 1 gram of water), controlled at About 1 hour to drip. After that, continue to pass high-...

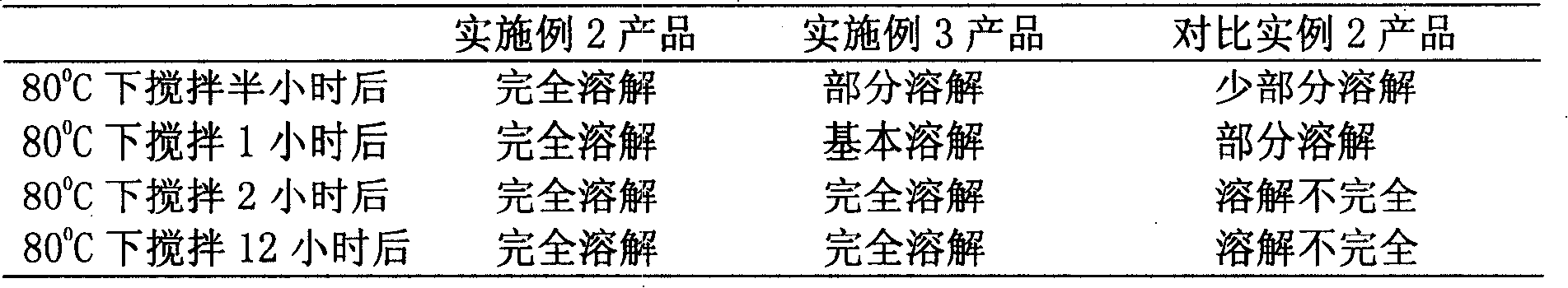

Embodiment 3

[0021]Example 3 Preparation of polyacrylamide inverse microemulsion with a solid content of 40%, an oil-water ratio of 0.6 Pass high-purity nitrogen into a 100ml three-necked bottle equipped with a condenser tube, an air guide tube and a mechanical stirrer to remove oxygen, and add 9.6 Gram 32# white oil, 4.8 grams of emulsifier SPAN80, 0.6 grams of self-made stabilizer obtained in Example 1, heat up to 50 ° C, after vigorously stirring for 10 minutes, add 23 grams of 60% acrylamide aqueous solution, continue stirring for half an hour, Then slowly add APS aqueous solution (0.03 gram of APS is dissolved in 1 gram of water), when the APS aqueous solution is added to about half of the total amount, start to slowly add dropwise ferric chloride aqueous solution (0.06 gram of ferric chloride is dissolved in 1 gram of water) ), controlled to finish dripping in about 1 hour. After that, continue to pass high-purity nitrogen to react for 3 hours, lower the temperature, and stop the rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com