Device and method for measuring metal film stress evolution when loading current

A metal thin film, a technique for measuring current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

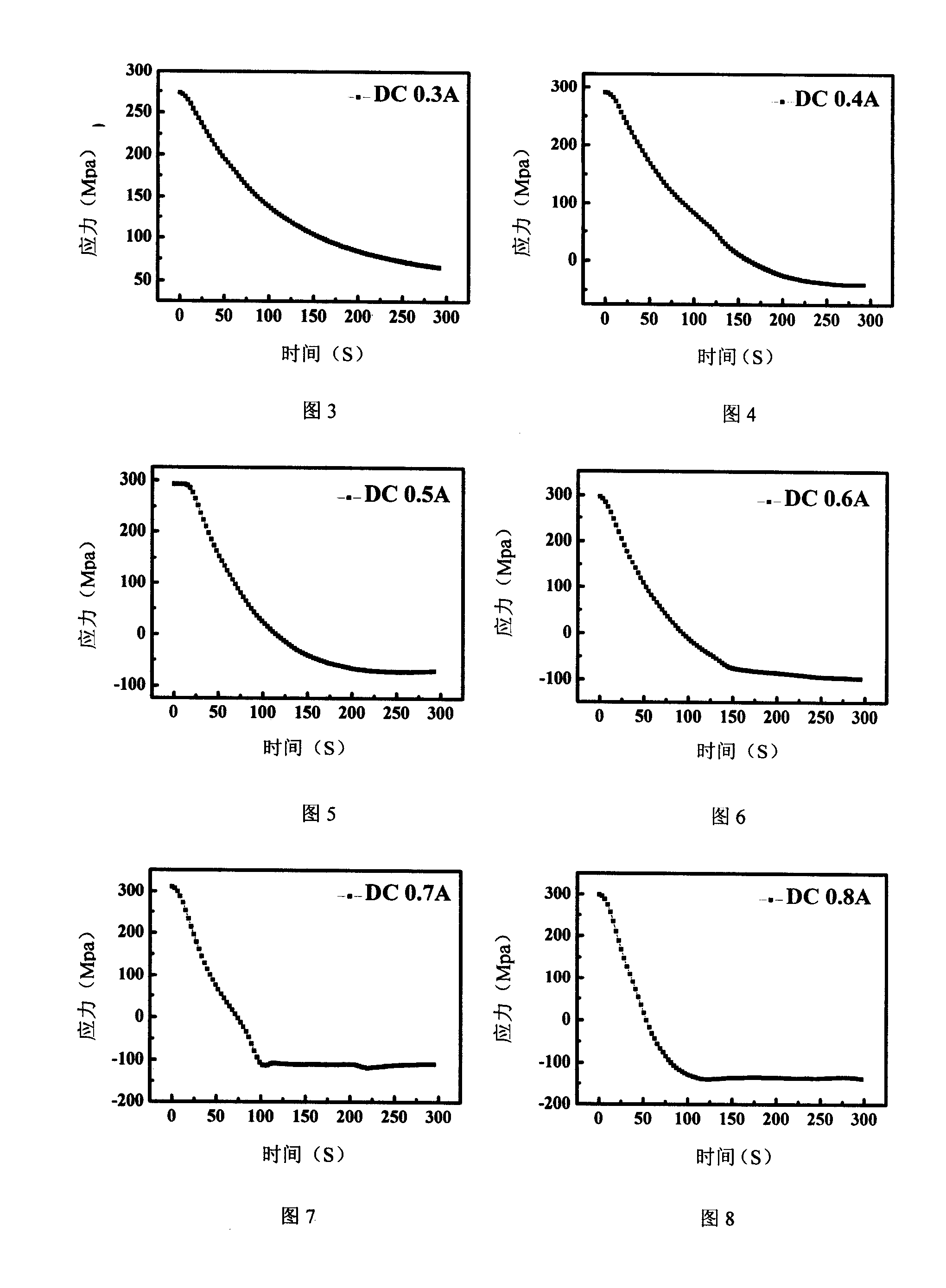

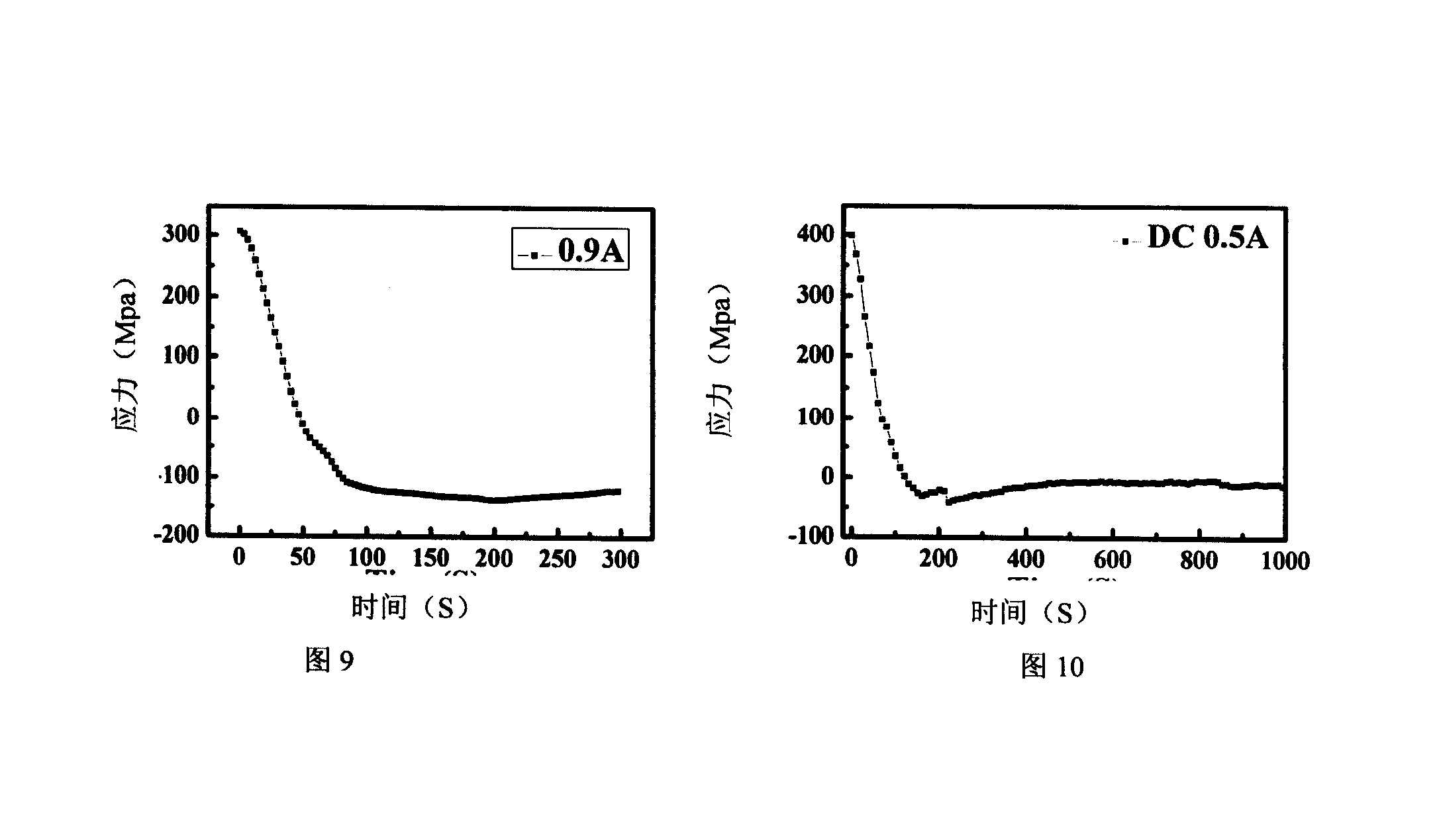

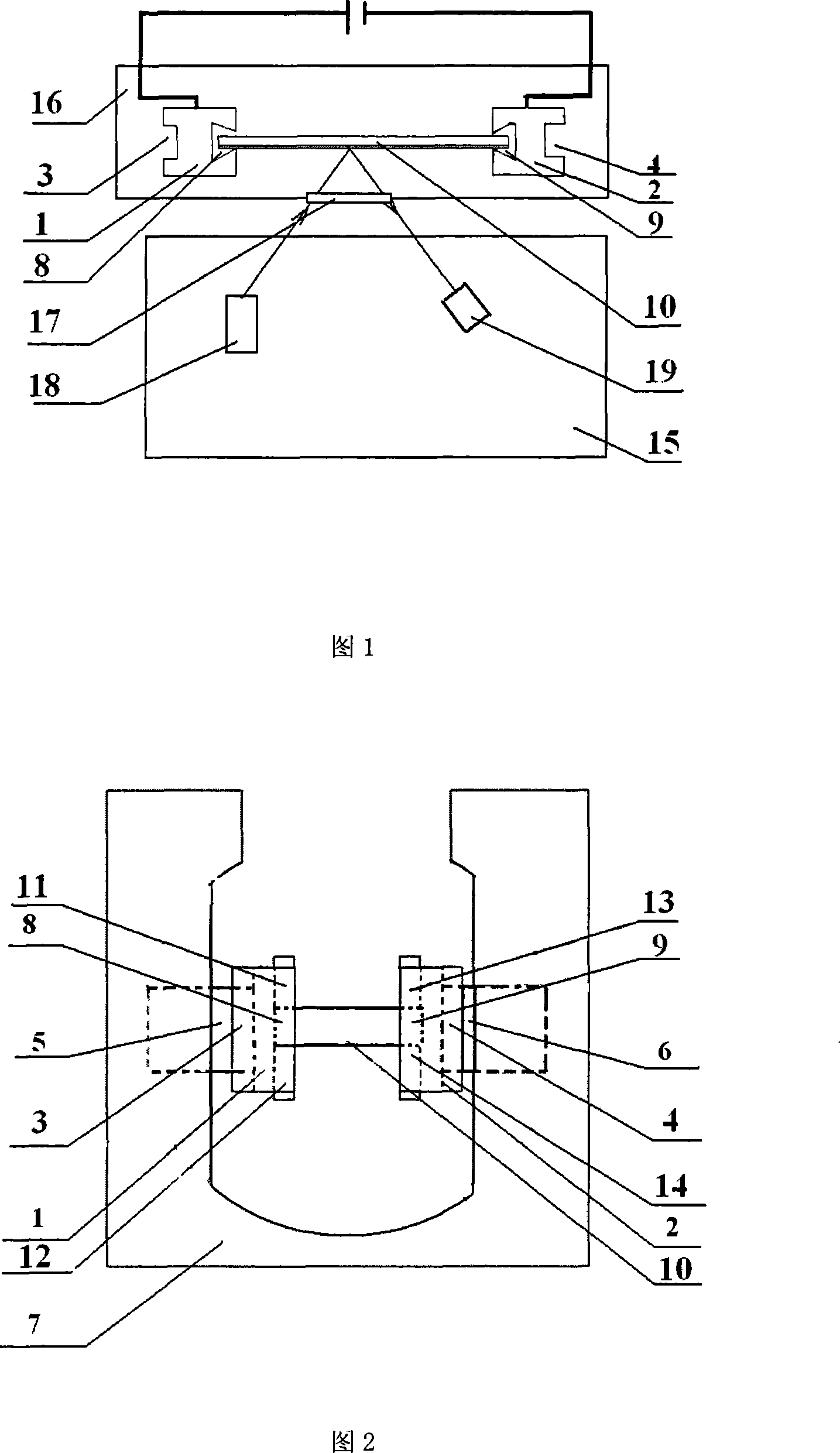

[0040] Embodiment 1: adopt magnetron sputtering deposition method that copper thin film is deposited on 2 inches thermally oxidized silicon chip: SiO2(50nm) / Si(380 μm) / SiO2(50nm), copper thin film thickness 1 μm, deposition process parameter is : sputtering power 100W; sputtering bias -80V; background vacuum: 1.0×10 -6 Pa; Working air pressure (Ar) 0.1Pa; Use a diamond scriber to cut it into a rectangular metal film sample 10 of 5mm * 15mm, place the rectangular metal film sample 10 from the first metal material placement table 1 underside and the second The lower side of the metal material placement table 2 is put into, the first metal plug 11 is inserted into the upper side of the first dovetail-shaped through groove 8, the second metal plug 12 is inserted into the lower side of the first dovetail-shaped through groove, and the second metal plug 12 is inserted into the lower side of the first dovetail-shaped through groove Three metal plugs 13 are inserted into the upper sid...

Embodiment 2

[0041] Embodiment 2: adopt magnetron sputtering deposition method to deposit copper thin film on 2 inches thermally oxidized silicon wafer: SiO2(50nm) / Si(380 μm) / SiO2(50nm), copper thin film thickness 1 μm, deposition process parameter is : sputtering power 100W; sputtering bias -80V; background vacuum: 1.0×10 -6 Pa; Working air pressure (Ar) 0.1Pa; Use a diamond scriber to cut it into a rectangular metal film sample 10 of 5mm * 15mm, place the rectangular metal film sample 10 from the first metal material placement table 1 underside and the second The lower side of the metal material placement table 2 is put into, the first metal plug 11 is inserted into the upper side of the first dovetail-shaped through groove 8, the second metal plug 12 is inserted into the lower side of the first dovetail-shaped through groove, and the second metal plug 12 is inserted into the lower side of the first dovetail-shaped through groove Three metal plugs 13 are inserted into the upper side of t...

Embodiment 3

[0042] Embodiment 3: adopt magnetron sputtering deposition method to deposit copper thin film on 2 inches thermally oxidized silicon wafer: SiO2(50nm) / Si(380 μm) / SiO2(50nm), copper thin film thickness 1 μm, deposition process parameter is : sputtering power 100W; sputtering bias -80V; background vacuum: 1.0×10 -6 Pa; Working air pressure (Ar) 0.1Pa; Use a diamond scriber to cut it into a rectangular metal film sample 10 of 5mm * 15mm, place the rectangular metal film sample 10 from the first metal material placement table 1 underside and the second The lower side of the metal material placement table 2 is put into, the first metal plug 11 is inserted into the upper side of the first dovetail-shaped through groove 8, the second metal plug 12 is inserted into the lower side of the first dovetail-shaped through groove, and the second metal plug 12 is inserted into the lower side of the first dovetail-shaped through groove Three metal plugs 13 are inserted into the upper side of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com