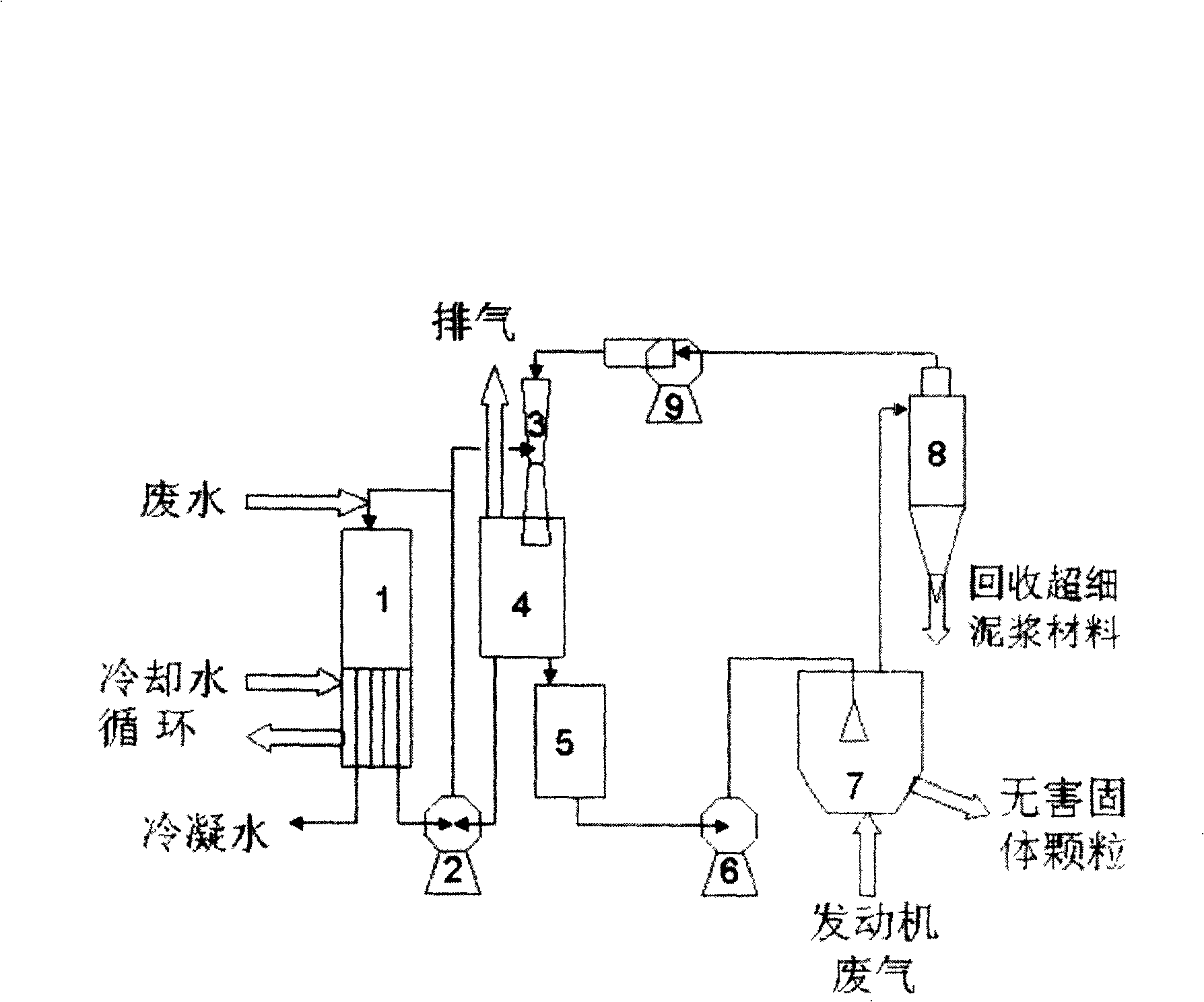

On-site comprehensive approach for wastewater, artesian well, waste slurry and engine waste gas

An engine, waste mud technology, applied in dewatering/drying/concentrating sludge treatment, chemical instruments and methods, heating water/sewage treatment, etc., can solve the problems of hidden environmental hazards and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] Example 1: 500kW diesel engine circulating cooling water treatment waste water 900kg / h and reclaim 855kg / h condensed water, engine exhaust treatment 260kg / h of waste mud with a solid rate of 33% and recycle 80kg / h ultrafine powder mud material Circulating water at 95-105°C convects and releases heat between the tubes of the first-effect falling-film heating section in the three-effect falling-film evaporator 1, so that the waste water pushed down by the fluid column in the second-effect falling-film heating section is heated in the tube to T eva1 =75~95℃ and film evaporation under the pressure drop of 38~84kPa, the evaporation intensity is 14~20kg / (h·m 2 ), the evaporation load is 220-315kg / h; the generated first-effect steam condenses and releases heat between the tubes of the second-effect falling-film heating section of device 1, so that the waste water pushed down by the liquid column in the third-effect falling-film heating section is heated in the tube warm up to...

Embodiment 2

[0011] Example 2: 500kW diesel engine circulating cooling water treats 900kg / h of waste water and recycles 855kg / h of condensed water, and treats 260kg / h of waste mud with a solid content of 33% in engine exhaust to make it thermally decompose at high temperature to achieve harmless 95~ The circulating water at 105°C convects and releases heat between the tubes of the first-effect falling-film heating section in the three-effect falling-film evaporator 1, so that the wastewater pushed down by the fluid column in the second-effect falling-film heating section is heated in the tube to T eva1 =75~95℃ and film evaporation under the pressure drop of 38~84kPa, the evaporation intensity is 14~20kg / (h·m 2 ), the evaporation load is 220-315kg / h; the generated first-effect steam condenses and releases heat between the tubes of the second-effect falling-film heating section of device 1, so that the waste water pushed down by the liquid column in the third-effect falling-film heating secti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com