Colored coating composition

A technique for coloring paints and compositions, applied to polyester paints, coatings, devices for coating liquids on surfaces, etc., capable of solving problems such as metallic stains, poor smoothness, and easy occurrence of metallic stains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

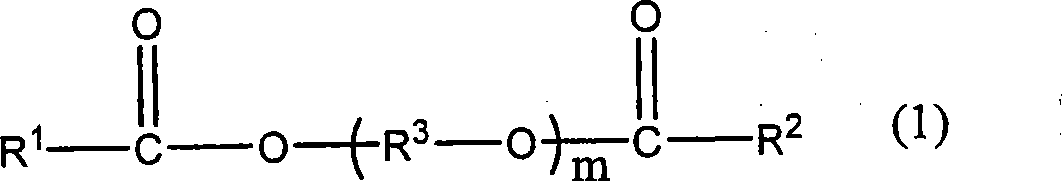

Method used

Image

Examples

manufacture example 1

[0199] In a reaction vessel equipped with a thermometer, a constant temperature box, a stirring device, a reflux condenser and a water separator, add 174 parts of trimethylolpropane, 327 parts of neopentyl glycol, 352 parts of adipic acid, and 109 parts of isophthalic acid. parts and 101 parts of 1,2-cyclohexanedicarboxylic acid anhydride, after raising the temperature to 160°C to 230°C over 3 hours, while using a water separator to distill off the condensation water, it was kept at 230°C to react until the acid The value is 3 mgKOH / g or less. Add 59 parts of trimellitic anhydride to this reaction product, and perform addition reaction at 170°C for 30 minutes, then cool to 50°C or lower, add 2-(dimethylamino)ethanol to acid group equivalent, and neutralize , deionized water was slowly added to obtain a hydroxyl-containing polyester resin solution (A1-1) with a solid content concentration of 45% and a pH of 7.2. The acid value of the obtained hydroxyl group-containing polyeste...

manufacture example 2

[0202] In a reaction vessel equipped with a thermometer, a constant temperature box, a stirring device, a reflux condenser and a water separator, add 168 parts of trimethylolpropane, 316 parts of neopentyl glycol, 93 parts of adipic acid, and 211 parts of isophthalic acid parts, 188 parts of phthalic anhydride, and 65 parts of 1,2-cyclohexanedicarboxylic anhydride. After raising the temperature to 160°C to 230°C over 3 hours, the water generated by the condensation reaction was distilled off with a water separator. , while keeping at 230°C, it was reacted until the acid value was 3 mgKOH / g or less. Add 59 parts of trimellitic anhydride to this reaction product, and perform addition reaction at 170°C for 30 minutes, then cool to 50°C or lower, add 2-(dimethylamino)ethanol to acid group equivalent, and neutralize , deionized water was slowly added to obtain a hydroxyl-containing polyester resin solution (A1-2) with a solid content concentration of 45% and a pH of 7.2. The obtai...

manufacture example 3

[0205] In a reaction vessel equipped with a thermometer, a constant temperature box, a stirring device, a reflux condenser and a water separator, add 166 parts of trimethylolpropane, 314 parts of neopentyl glycol, 338 parts of adipic acid and 1,2-cyclo 194 parts of hexanedicarboxylic acid anhydride, heated up to 160°C to 230°C over 3 hours, kept at 230°C while distilling off the water generated by the condensation reaction with a water separator, and reacted until the acid value was 3mgKOH / g or less. Add 94 parts of 1,2-cyclohexanedicarboxylic acid anhydride to this reaction product, and perform addition reaction at 170°C for 30 minutes, then cool to below 50°C, and add 2-(dimethyl (amino)ethanol and neutralized, deionized water was slowly added to obtain a hydroxyl-containing polyester resin solution (A1-3) with a solid content concentration of 45% and a pH of 7.2. The obtained hydroxyl group-containing polyester resin had an acid value of 35 mgKOH / g, a hydroxyl value of 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com