Microwave auxiliary extraction method of silybum marianum seed oil

A technology of milk thistle seed oil and microwave assisted, applied in the field of food processing, can solve the problems of low extraction rate, low production efficiency, limited extraction of trace substances and the scope of laboratory research, etc., and achieves simple experimental device and heating speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The preliminary test of embodiment 1 single factor

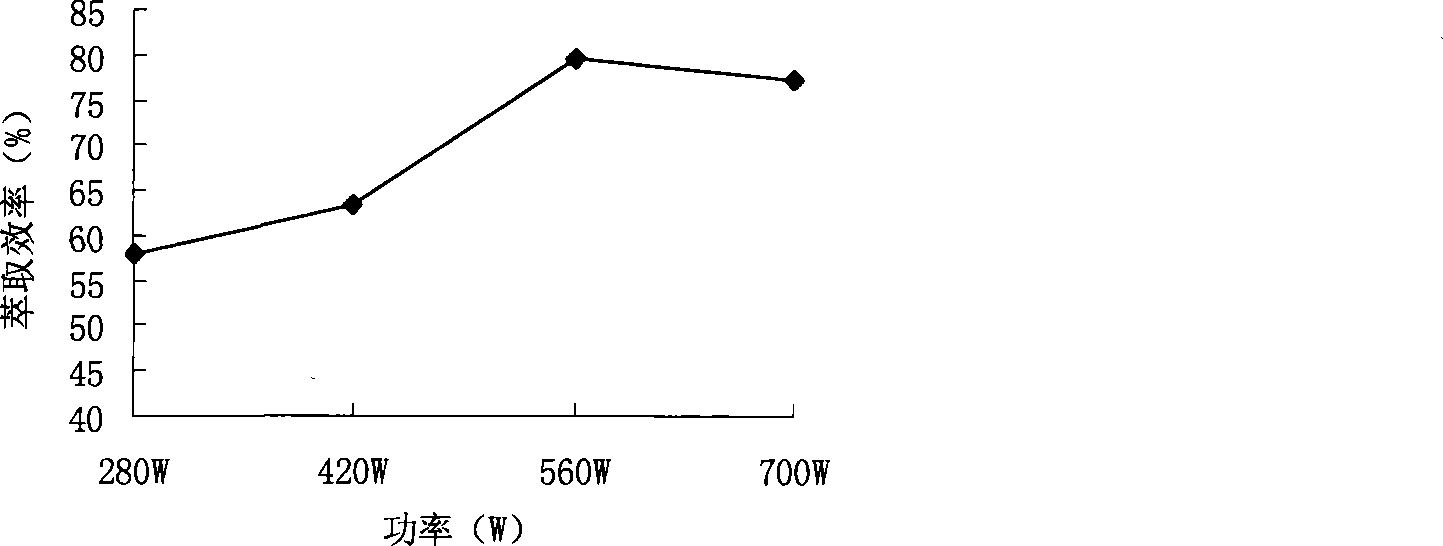

[0023] 1. The effect of microwave power on the extraction of milk thistle seed oil

[0024] In the microwave-assisted extraction process, microwave power is one of the most important factors affecting the extraction effect. This experiment investigated the changes in the extraction effect when the microwave power was 280W, 420W, 560W, and 700W. The results are as follows: figure 1 .

[0025]Microwave extraction is to use a kind of radiation energy with extremely short wavelength and high frequency to process materials. The cell wall of Agaricus blazei absorbs microwave energy, and the tissue molecules produce instantaneous polarization under the action of microwave electromagnetic field, and polarize at a speed of 245 million times per second. Change motion, produce bond vibration, fracture, and mutual friction and collision between particles, so that the inside of the vascular bundle tissue heats up sharply, and can...

Embodiment 2

[0033] 1. Test method

[0034] 1. Sample processing After vacuum-drying the seeds of milk thistle, crush them with a multifunctional food blender and pass through 40 meshes for use.

[0035] 2 Soxhlet extraction method Accurately weigh 10 g of the above-mentioned milk thistle seed powder, degrease with petroleum ether in a Soxhlet extractor for 10 hours, and calculate the extraction rate of milk thistle seed oil.

[0036] 3 Microwave extraction method Accurately weigh 10g of the above seed powder, put it into a conical flask, and add a certain amount of organic solvent. Put the Erlenmeyer flask into a microwave oven and radiate for a certain period of time (intermittent radiation is used to prevent bumping). Then filter and wash the filter residue, transfer the filtrate and washing solution into a conical flask, heat in a water bath to remove the organic solvent, then dry it, and weigh the quality of the milk thistle seed oil. The fat content is determined according to the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Microwave power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com