Metallic filtering film with antisymmetric structure and method of preparing the same

A technology of metal filter membrane and asymmetric structure, which is applied in the field of metal filter membrane with asymmetric structure and its preparation, can solve the problems of affecting the service life of the line and the effect is not very good, so as to improve the filtration efficiency and adhesion , the effect of fluid flux increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

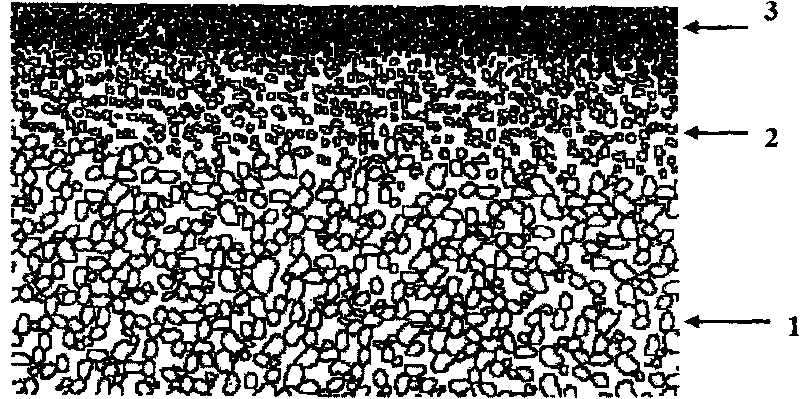

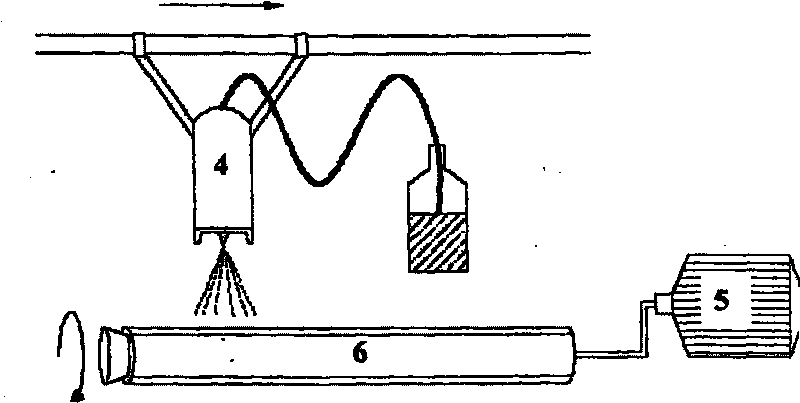

[0023] Example 1: A disk-shaped 316L stainless steel support was used to prepare an asymmetric structural metal film. The main chemical components were: Cr: 16.5%, Ni: 12.4%, Mo: 2.1%, Mn: 0.6%, Si: 1.2%, C: 0.03%, the balance is Fe, the diameter of the disc is 10cm, the thickness is 3mm, the average pore diameter of the support body is 10μm, the porosity is 45%, and the suspension slurry contains 0.5% Carbopol (Carbopol), liquid The phase was pure water, and the weight ratio of metal powder to liquid phase was 2.5:1. The metal powder is stainless steel 316L powder atomized by inert gas, with an average particle size of 3μm; after the slurry is fully stirred and mixed, it is evenly sprayed on the surface of the disc support with a modified spray gun, and then dried at room temperature for 24 hours. While coating the film, a vacuum of -0.3 atm was applied on the uncoated side of the disc; the dried workpiece was vacuum sintered at a temperature of 930° C. for 2.0 hours. The th...

Embodiment 2

[0024] Example 2: A tubular metal support was used to prepare a filter membrane with a non-paired structure. The diameter of the tube was 50 mm, the length was 200 mm, the wall thickness was 2.5 mm, and the porosity of the tubular support was 45%. The average pore diameter is 20 μm, its material is stainless steel 316L, and its chemical composition is the same as that described in Example 1. The metal powder used for the coating film is an inert gas atomized stainless steel 316L powder with an average particle size of 10 μm. The formulation of the coating slurry was the same as described in Example 1. After the slurry was thoroughly stirred and mixed, it was uniformly sprayed onto the outer surface of the tubular support with a modified spray gun, and then dried at room temperature for 24 hours. While coating the film, a vacuum of -0.3 atm was applied in the tube; the dried workpiece was vacuum sintered at a temperature of 1100° C. for 2.0 hours. The sintered filtration contr...

Embodiment 3

[0025] Example 3: This example describes the preparation method of the asymmetric structure of the two-layer film, the preparation method and process conditions of the metal support and the first layer film (transition layer) are exactly the same as those described in Example 2, In this example, a filtration control layer (second layer) with higher filtration precision is also coated on the first film (transition layer), and the metal powder used for preparing the filtration control layer is also produced by inert gas atomization. The average particle size is 1.5 μm, the suspension slurry contains 0.5% Carbopol, the liquid phase is pure water, and the weight ratio of metal powder to liquid phase is 2.5:1; Sintered for 2 hours. The thickness of the second membrane (the filtration control layer) is about 0.1 mm, and the average pore size is about 0.2 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com