Steel slag baking-free brick

A technology for unburned bricks and steel slag, which is applied in the field of steel slag unburned bricks to achieve the effects of reducing accumulation, reducing environmental pollution and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

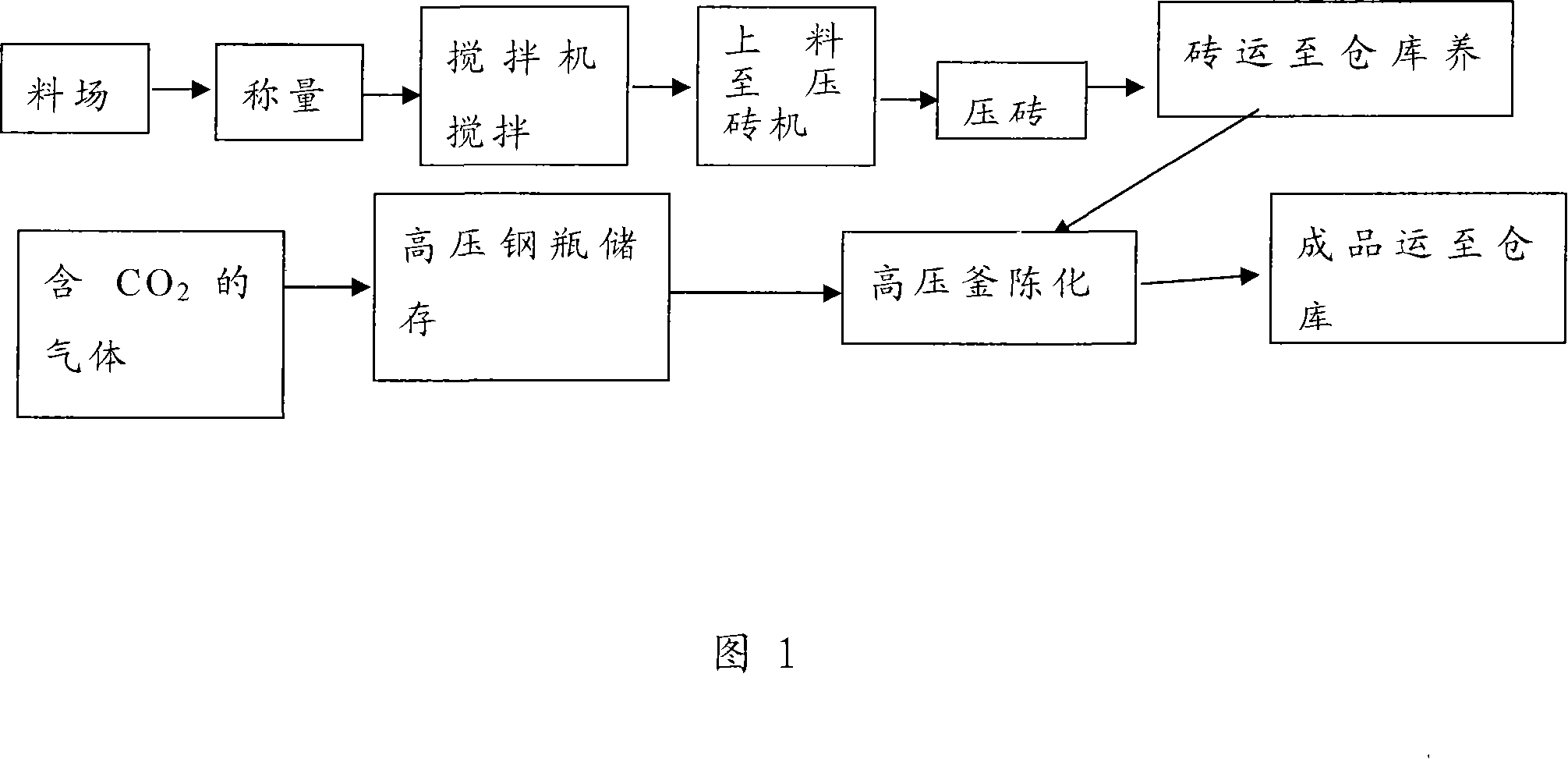

Method used

Image

Examples

Embodiment 1

[0029] Take 10 parts of steel slag sand, 40 parts of steel slag powder, 50 parts of blast furnace slag, 5 parts of lime, add 10 parts of water, mix evenly with a mixer, feed the material to the brick pressing mold, press it with a brick pressing machine, and put the pressed The bricks are stored in the warehouse under natural conditions for 3 days, and the cured bricks are placed in a high-pressure container. At room temperature, CO 2 Gas (purity is 20%), the aging pressure is 0.1MPa, and the aging time is 36h. The average compressive strength of the obtained steel slag unburned brick is: 15MPa, and the strength of 80% of the products can reach 18MPa. After boiling for 3h, Inspection after pressure steaming for 3 hours, the stability is all qualified. See the table below for various performance data.

[0030] project

[0031] C K

Embodiment 2

[0033] Take 10 parts of steel slag sand, 40 parts of steel slag powder, 50 parts of blast furnace slag, 5 parts of lime, add 10 parts of water, mix evenly with a mixer, feed the material to the brick pressing mold, press it with a brick pressing machine, and put the pressed The bricks are stored in the warehouse under natural conditions for 3 days, and the cured bricks are placed in a high-pressure container. At room temperature, CO 2 Gas (purity is 90%), the aging pressure is 0.1MPa, the aging time is 3h, the average compressive strength of the obtained steel slag unburned brick is: 20MPa, wherein the strength of 50% of the product can reach 25MPa, after boiling for 3h, Inspection after pressure steaming for 3 hours, the stability is all qualified. See the table below for various performance data.

[0034] project

[0035] power level

Embodiment 3

[0037] Take 10 parts of steel slag sand, 40 parts of steel slag powder, 60 parts of blast furnace slag, 5 parts of lime, add 10 parts of water, mix evenly with a mixer, feed the material to the brick press mold, press it with a brick press, and put the pressed The bricks are stored in the warehouse under natural conditions for 3 days, and the cured bricks are placed in a high-pressure container. At room temperature, CO 2 Gas (purity is 20%), the aging pressure is 0.5MPa, and the aging time is 20h, the average compressive strength of the obtained steel slag unburned brick is: 15MPa, and the strength of 80% of the products can reach 18MPa, after boiling for 3h, Inspection after pressure steaming for 3 hours, the stability is all qualified. See the table below for various performance data.

[0038] project

[0039] thickness

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| molar volume | aaaaa | aaaaa |

| molar volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com